Author: Denis Avetisyan

Researchers have developed a soft robotic wrist that dynamically adjusts its stiffness, enabling more robust and adaptable performance in complex, contact-rich tasks.

A novel soft wrist, called CLAW, demonstrates improved learning and performance in manipulation tasks like peg-in-hole insertion and real-world object handling through anisotropic and selectable stiffness.

Robust robot learning in contact-rich manipulation is challenged by unpredictable collisions that hinder performance and risk damage. This limitation motivates the research presented in ‘A Soft Wrist with Anisotropic and Selectable Stiffness for Robust Robot Learning in Contact-rich Manipulation’, which introduces CLAW, a novel soft wrist mechanism offering large deformation ranges and tunable anisotropic stiffness. Experimental results demonstrate that CLAW achieves significantly improved success rates in benchmark tasks like peg-in-hole insertion compared to both rigid and conventional soft grippers. Could this adaptable compliance unlock more robust and versatile robotic systems capable of navigating complex, real-world environments?

The Algorithmic Imperative: Bridging Precision and Uncertainty

Conventional robotic grippers, prominently exemplified by the Rigid Parallel Gripper, often falter when confronted with the unpredictable nature of real-world assembly. These devices, designed for precision in controlled environments, lack the adaptability needed to accommodate variations in object position, orientation, and shape – factors commonly encountered in unstructured settings. Minute discrepancies, such as a slightly misaligned part or an unexpected obstruction, can disrupt the grasping process and lead to assembly failures. The rigidity inherent in these designs prevents them from conforming to the object or absorbing minor impacts, making them susceptible to slippage or complete loss of contact. This limitation highlights a critical challenge in robotics: bridging the gap between the predictable precision of automated systems and the inherent uncertainties of the physical world.

The difficulty many robotic systems experience during assembly arises from a fundamental rigidity in their design. Traditional grippers, while precise, lack compliance – the ability to yield and adapt to contact forces. This inflexibility proves problematic when interacting with real-world objects, which invariably exhibit variations in shape, position, and surface properties. Upon initial contact, a rigid gripper may exert excessive force, leading to slippage, instability, or even damage to delicate components. Consequently, assembly attempts frequently fail, as the robot is unable to maintain a secure and stable grasp despite seemingly accurate positioning. This highlights a critical need for robotic manipulation systems that can actively sense and respond to contact forces, effectively ‘feeling’ their way through assembly tasks and accommodating the inherent uncertainties of the physical world.

Truly autonomous robotic manipulation demands more than just precise movements; it necessitates a system’s ability to dynamically respond to the unpredictable nature of physical interaction. Current robotic systems often falter when confronted with variations in object pose, unexpected collisions, or imprecise environments, as maintaining stable contact-the foundation of successful assembly or delicate handling-becomes exceedingly difficult. Researchers are actively developing strategies to imbue robots with enhanced sensing capabilities and compliant actuators, allowing them to detect and react to unforeseen circumstances in real-time. This involves not just correcting for disturbances, but proactively anticipating them, and adjusting grip force and trajectory accordingly to preserve stable contact and successfully complete manipulation tasks – ultimately bridging the gap between controlled laboratory settings and the complexities of the real world.

CLAW: A Paradigm Shift in Variable Stiffness Design

CLAW represents a departure from conventional robotic wrist designs by incorporating variable stiffness capabilities. Traditional robotic manipulators often utilize rigid links and joints, limiting adaptability and potentially causing damage during contact with uncertain environments or delicate objects. CLAW addresses these limitations through a soft wrist construction, allowing for compliance and force distribution. This variable stiffness is not a fixed property, but rather a dynamically adjustable characteristic, enabling the wrist to transition between flexible and rigid states as needed for different manipulation tasks. The design aims to improve robustness, safety, and overall performance in scenarios requiring delicate interaction or operation in unstructured environments.

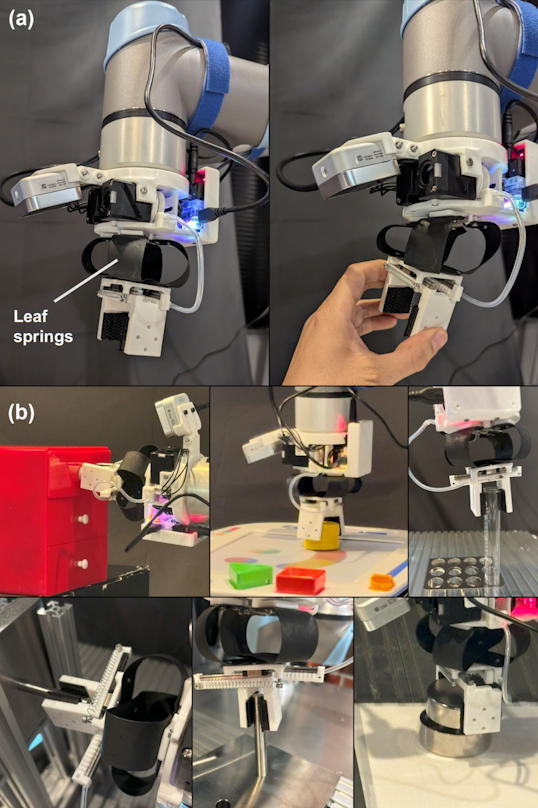

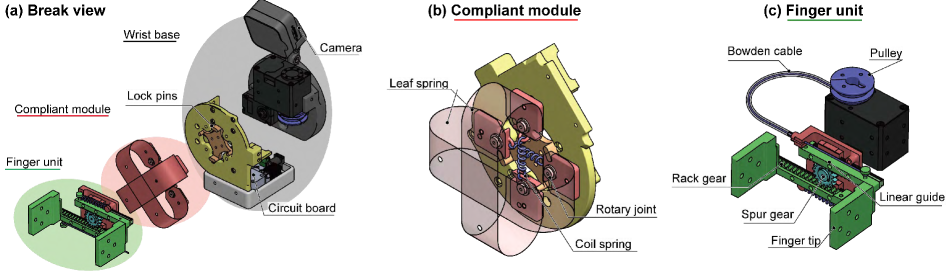

CLAW’s mechanical design centers around the integration of leaf springs and convex tape to achieve a balance between flexibility and stability within a constrained volume. The leaf springs provide inherent compliance, enabling the wrist to conform to grasped objects and external forces. Convex tape, bonded to the leaf springs, introduces pre-tension and structural rigidity, preventing unwanted buckling and maintaining positional accuracy. This combination allows CLAW to exhibit multi-directional bending while resisting deformation under load, resulting in a compact and robust variable stiffness mechanism suitable for delicate or demanding manipulation tasks.

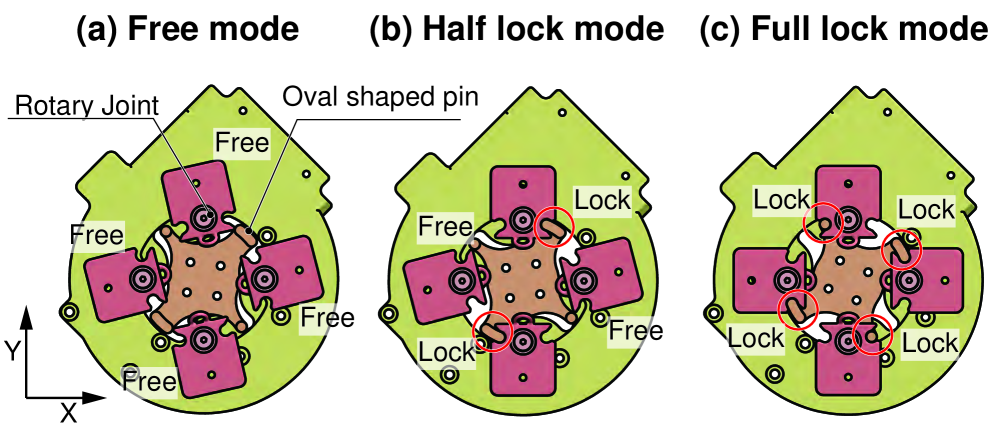

CLAW’s integrated locking mechanism provides adaptable rigidity through three distinct configurations. In Free Mode, all locking elements are disengaged, allowing for maximum flexibility and suitability for tasks requiring unconstrained movement or delicate contact. Half-Lock Mode engages a subset of the locking elements, providing intermediate stiffness for applications needing partial stabilization while retaining a degree of compliance. Full-Lock Mode engages all locking elements, creating a rigid structure ideal for tasks demanding precise positioning and high force transmission. Transitions between these modes are designed to be seamless and rapid, enabling CLAW to dynamically adjust its stiffness in response to varying task requirements without interrupting operation.

Empirical Validation: CLAW’s Superior Performance on the Functional Manipulation Benchmark

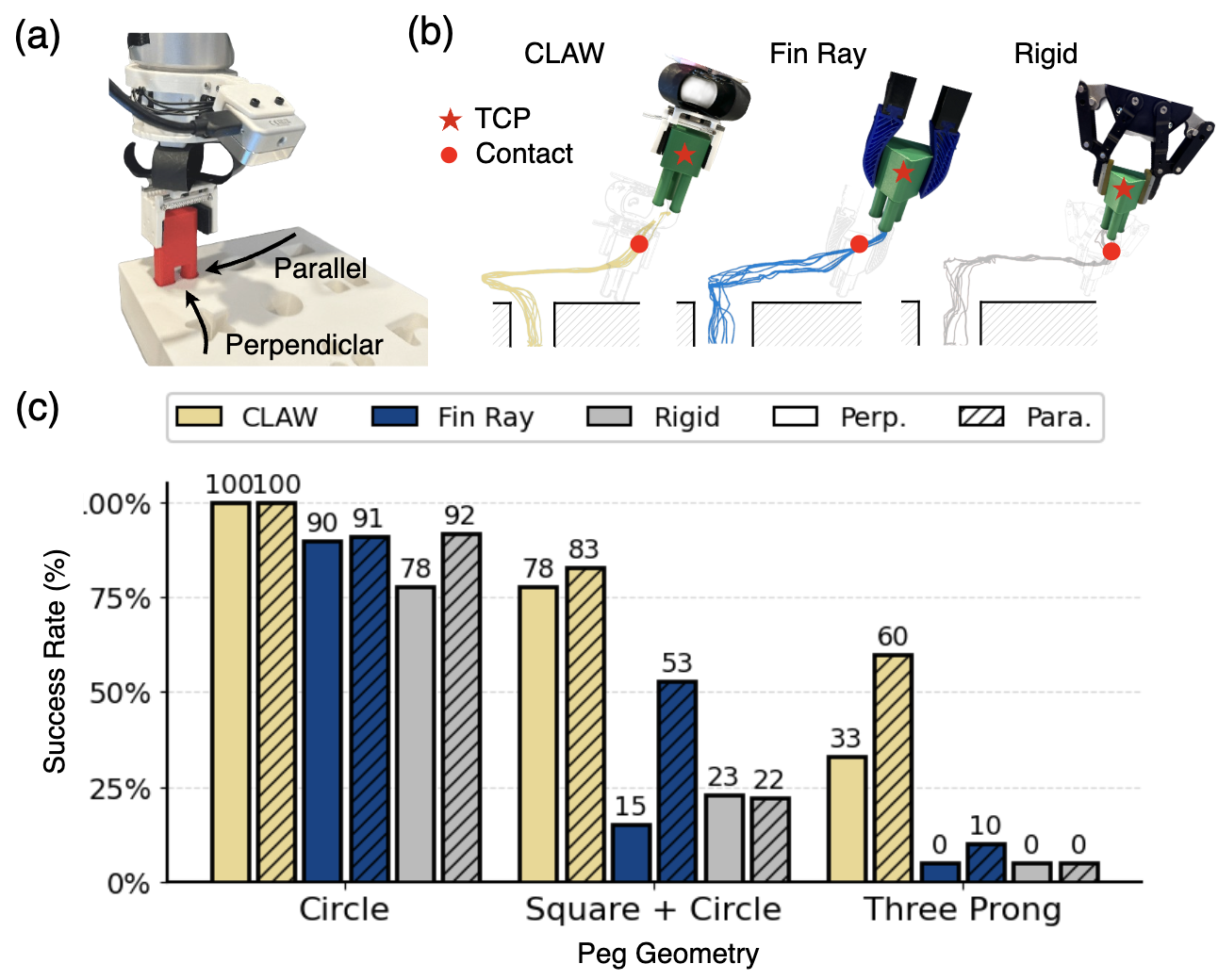

The Functional Manipulation Benchmark (FMB) provides a standardized assessment of robotic manipulation capabilities, specifically focusing on assembly tasks requiring dexterity and precision. This benchmark suite consists of a series of peg-in-hole insertions with varying peg geometries, approach angles, and insertion directions, allowing for quantitative comparison of different robotic grippers and control strategies. Utilizing the FMB ensures objective evaluation, moving beyond subjective assessments of robotic performance and providing statistically relevant data for benchmarking and improvement. The FMB’s defined tasks and success criteria enable researchers and developers to isolate and analyze specific aspects of robotic manipulation, such as grasping, insertion, and force control.

During evaluation using the Functional Manipulation Benchmark (FMB) peg-in-hole tasks, the CLAW gripper achieved an overall success rate of 76%. This performance represents a statistically significant improvement over two baseline grippers: the Fin Ray gripper, which achieved a 43% success rate, and a standard rigid gripper, which achieved 36%. These results indicate CLAW’s enhanced capabilities in performing precision manipulation tasks as defined by the FMB.

During Functional Manipulation Benchmark (FMB) testing, CLAW demonstrated a 76% success rate when attempting insertion of a 3-prong peg using a perpendicular approach. This performance metric represents a significant improvement over both comparison grippers; the Fin Ray gripper and a rigid gripper each achieved a success rate of only 36% on the same task. The substantial difference in success rates indicates CLAW’s superior ability to handle the complexities introduced by the peg’s geometry and the perpendicular insertion angle, which requires precise manipulation and force control.

Quantitative evaluation of CLAW’s performance on square+circle peg insertion tasks, conducted with a parallel approach direction, revealed a significant advantage over the Fin Ray gripper. CLAW achieved a success rate four times greater than that of the Fin Ray gripper in these specific tasks. This data indicates CLAW’s superior ability to manage the geometric complexities inherent in inserting non-circular pegs, particularly when aligned for a parallel insertion attempt. The observed performance difference highlights CLAW’s enhanced dexterity and control mechanisms in accommodating varied peg shapes and orientations.

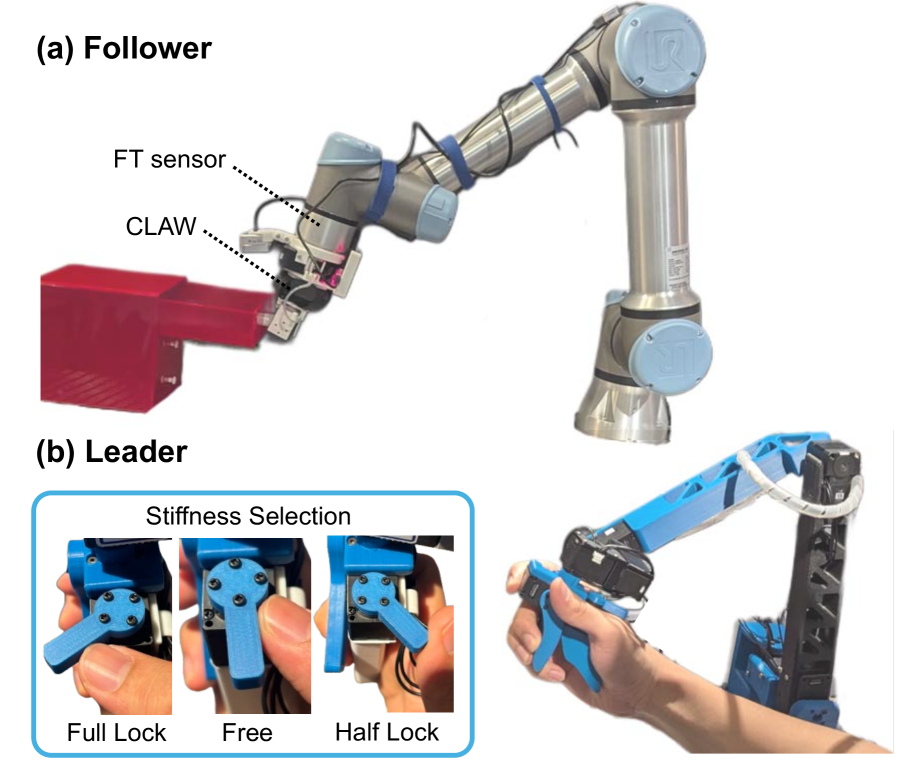

CLAW’s stability and precision are significantly enhanced through the implementation of advanced control strategies. These strategies center on a Forward Dynamics Compliance Controller, which predicts and compensates for external disturbances by modeling the robot’s dynamic behavior. Crucially, this controller is integrated with feedback from a Six-Axis Force/Torque (FT) sensor. The FT sensor measures forces and torques applied to the gripper, providing real-time data used to adjust the controller’s parameters and ensure precise manipulation, even in the presence of uncertainty or contact with the environment. This combination enables CLAW to maintain stable grasps and execute complex assembly tasks with increased accuracy and robustness.

During door opening tasks, CLAW exhibited a measurable reduction in applied force upon transitioning from Full-lock mode to Free mode. Data indicated a sharp decrease in resistance, signifying that Free mode allows for greater compliance and reduces the force required to manipulate the door handle. This suggests that CLAW’s Free mode effectively minimizes interaction forces during the initial stages of door opening, potentially preventing forceful impacts or unnecessary strain on the mechanism and allowing for a smoother, more energy-efficient operation compared to maintaining a rigid Full-lock configuration.

Towards a Future of Adaptable Robotics: The Implications of Variable Stiffness

Current force-controlled robots, while precise, often struggle with unpredictable environments and delicate interactions due to their rigid structures and limited adaptability. The development of CLAW signifies a move beyond these limitations, offering a robotic system engineered for enhanced robustness and flexibility. Unlike traditional robots that resist external forces, CLAW utilizes principles of soft robotics and variable stiffness to conform to its surroundings and absorb impacts. This allows for more reliable operation in cluttered or dynamic workspaces, and enables safer, more intuitive collaboration with humans. By prioritizing compliance and adaptability, CLAW doesn’t simply react to disturbances – it anticipates and accommodates them, representing a crucial advancement towards robotic systems capable of truly versatile performance in real-world scenarios.

The development of CLAW signifies a departure from traditional rigid robotics, instead leveraging the principles of Soft Robotics and Variable Stiffness to redefine interaction and capability. This approach allows the robot to conform to grasped objects, distributing forces evenly and preventing damage-a crucial element for delicate assembly or collaborative tasks with humans. By modulating stiffness, CLAW can transition seamlessly between firm, precise movements for structural work and compliant, adaptable responses for safe human interaction. This dynamic control not only enhances dexterity in complex environments but also reduces the risk of injury during shared workspaces, opening doors to applications where robots and humans work in close proximity on intricate procedures, such as electronics manufacturing or surgical assistance.

The innovative design principles underpinning CLAW – a robotic system exhibiting both adaptability and force compliance – are not limited to a single platform. Researchers envision these strategies being readily transferable to a diverse array of robotic morphologies, from delicate surgical instruments to large-scale industrial manipulators. This scalability stems from a core focus on variable stiffness control and soft robotics principles, allowing for the creation of robots capable of navigating unpredictable environments and interacting safely with complex objects. By decoupling actuator power from physical rigidity, CLAW’s approach facilitates the development of machines exhibiting heightened dexterity, improved energy efficiency, and a significantly expanded operational envelope – ultimately fostering a future where robots are not simply automated tools, but truly versatile and intelligent collaborators.

The pursuit of robust robotic manipulation, as demonstrated by CLAW, necessitates a departure from rigid, pre-defined solutions. This research champions a system where adaptability-specifically, anisotropic and selectable stiffness-becomes paramount. It echoes Barbara Liskov’s sentiment: “It’s one of the most powerful things about programming-you can design a system to be extended.” CLAW isn’t merely a gripper; it’s a programmable foundation for contact-rich tasks, capable of evolving its behavior to meet unforeseen challenges. The core concept of variable stiffness isn’t simply about achieving flexibility, but about creating a system that can be rigorously proven to handle a broader range of scenarios, a testament to mathematical purity in design.

What Remains to Be Proven?

The demonstrated gains in manipulation, while empirically sound, merely shift the locus of the problem. The presented CLAW mechanism offers a tunable compliance, yet the derivation of optimal stiffness profiles for arbitrary contact-rich tasks remains largely heuristic. The algorithms employed, reliant on imitation learning, inherit the limitations of the demonstrator – a subtle point often overlooked in the rush to showcase ‘performance.’ True elegance would lie not in mimicking successful actions, but in deriving them a priori from first principles of mechanics and contact dynamics.

Furthermore, the anisotropic stiffness, while a logical progression beyond isotropic compliance, introduces a higher-dimensional parameter space for control. The current approach, while functional, lacks a formal justification for the chosen anisotropy directions. One suspects that optimal performance demands a stiffness tensor tailored not just to the task, but to the specific geometry of the manipulated object – a level of geometric awareness currently absent. The claim of ‘robustness’ requires rigorous mathematical definition, beyond mere resilience to minor perturbations.

Ultimately, this work highlights a persistent tension within the field. The pursuit of ‘soft’ robotics often prioritizes adaptability over predictability. However, without a corresponding investment in provably correct control algorithms, such systems risk becoming sophisticated, yet fundamentally unpredictable, instruments. The path forward lies not merely in building more compliant mechanisms, but in developing the mathematical frameworks to truly understand-and therefore control-their behavior.

Original article: https://arxiv.org/pdf/2602.14434.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- MLBB x KOF Encore 2026: List of bingo patterns

- Overwatch Domina counters

- Honkai: Star Rail Version 4.0 Phase One Character Banners: Who should you pull

- eFootball 2026 Starter Set Gabriel Batistuta pack review

- Brawl Stars Brawlentines Community Event: Brawler Dates, Community goals, Voting, Rewards, and more

- Lana Del Rey and swamp-guide husband Jeremy Dufrene are mobbed by fans as they leave their New York hotel after Fashion Week appearance

- 1xBet declared bankrupt in Dutch court

- Gold Rate Forecast

- eFootball 2026 Jürgen Klopp Manager Guide: Best formations, instructions, and tactics

- Breaking Down the Ending of the Ice Skating Romance Drama Finding Her Edge

2026-02-17 18:47