Author: Denis Avetisyan

Researchers have developed a novel sensing system for electro-ribbon actuators, enabling more precise and adaptable movements in soft robotic systems.

Integrated optical sensors and machine learning algorithms provide accurate curvature analysis for electro-ribbon actuators, addressing a critical gap in proprioceptive feedback.

Despite their potential for high-displacement, fast-paced movements, electro-ribbon actuators (ERAs) have long been limited by imprecise proprioceptive feedback. This paper introduces the ‘Optically Sensorized Electro-Ribbon Actuator (OS-ERA)’, a novel approach integrating soft optical waveguide sensors and machine learning to reliably classify bending states and resolve this longstanding bottleneck. By analyzing curvature through embedded sensors and training a classifier, we demonstrate accurate and repeatable performance even with variations in actuation speed and voltage. Could this advancement pave the way for truly closed-loop control and expanded applications of ERA technology in soft robotics and beyond?

Beyond Rigid Constraints: Re-Engineering Movement

Conventional robotics, historically dominated by systems built with rigid materials like metals and hard plastics, frequently struggles when operating in unpredictable or delicate surroundings. These structures, while offering precision in controlled settings, inherently lack the flexibility to safely interact with complex environments or handle fragile objects. This rigidity poses significant challenges in applications ranging from medical procedures and search-and-rescue operations to collaborative robotics working alongside humans. The inflexibility not only limits a robot’s adaptability but also introduces potential safety hazards, as unexpected collisions can result in damage to both the robot and its surroundings. Consequently, a shift towards more compliant and adaptable robotic systems is gaining momentum, driven by the need for robots that can navigate and interact with the world in a more natural and secure manner.

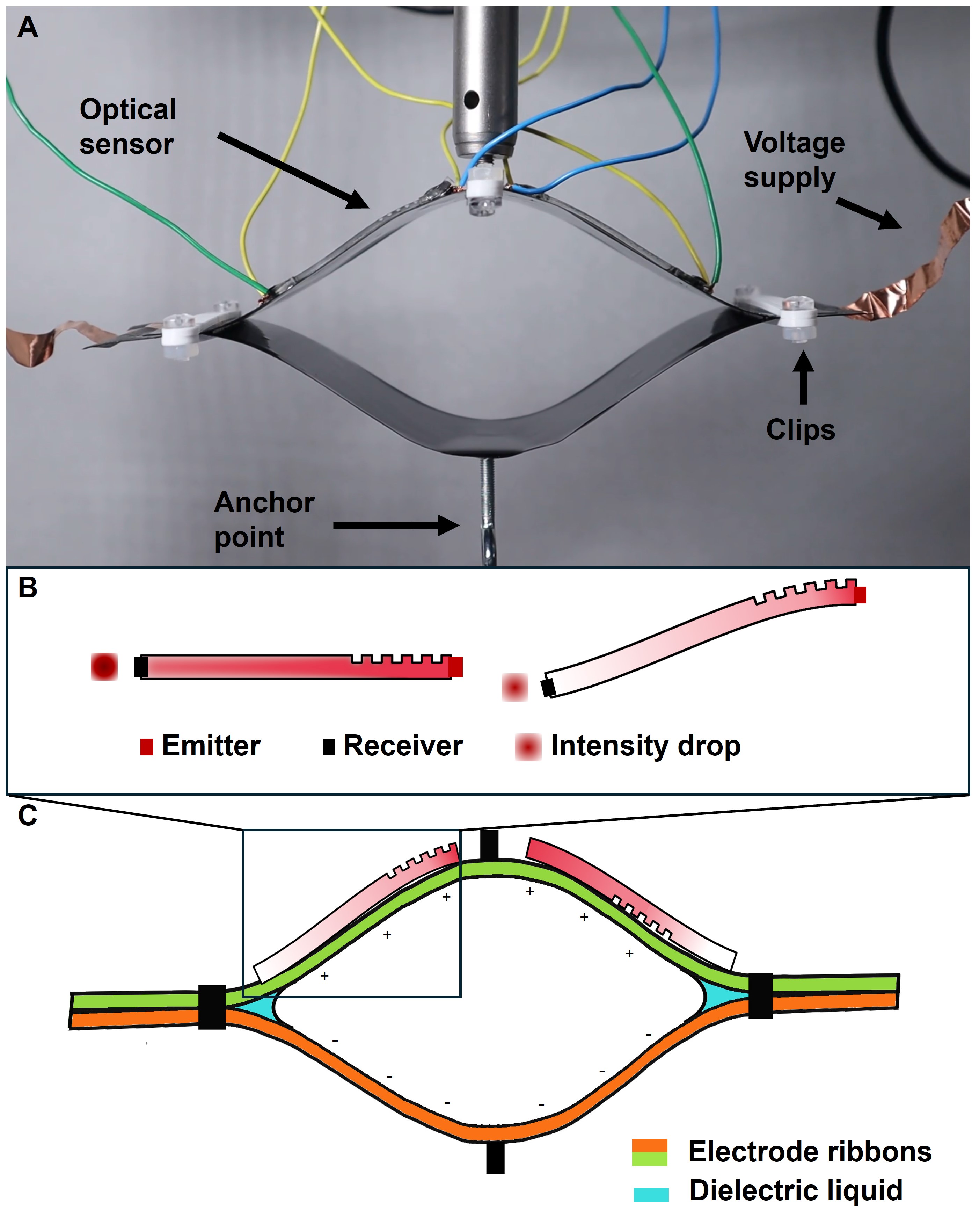

Electro-Ribbon Actuators (ERAs) represent a significant departure from traditional robotic systems, offering a pathway to remarkably adaptable and safe machines. These actuators achieve motion through electrostatic attraction between a patterned electrode and a grounded conductive ribbon, resulting in a surprisingly high force-to-weight ratio and inherent compliance. Unlike bulky motors and rigid linkages, ERAs are constructed from pliable materials, allowing them to conform to irregular surfaces and navigate constrained spaces with reduced risk of damage or injury. This lightweight nature also drastically reduces the energy required for operation, opening doors to untethered, long-duration robotic applications. The fundamental principle allows for intricate movements-bending, stretching, and gripping-all while maintaining a gentle, biologically-inspired interaction with the environment, making them ideal candidates for applications in prosthetics, minimally invasive surgery, and delicate manipulation tasks.

Electro-Ribbon Actuators, despite their promise of flexible and powerful movement, are susceptible to instabilities that present significant control challenges. A primary concern is “pull-in instability,” a phenomenon where the electrostatic force attracting the actuator’s ribbons rapidly increases as they approach each other, leading to unpredictable snapping motions and a loss of fine motor control. This effect isn’t merely a nuisance; it fundamentally limits the precision with which these actuators can be commanded, hindering their application in tasks demanding delicate manipulation or sustained positioning. Researchers are actively investigating various strategies – including advanced control algorithms and clever mechanical designs – to mitigate pull-in and unlock the full potential of ERA-based soft robotics, aiming for systems that are both powerful and reliably precise.

Realizing the full capabilities of Electro-Ribbon Actuator (ERA)-driven soft robots hinges on the development of robust and integrated sensing systems. While ERAs offer unprecedented flexibility and power, their inherent compliance introduces complexities in positional control; without precise feedback, these robots are prone to inaccuracies and instabilities. Advanced sensing modalities-ranging from capacitive and piezoresistive sensors embedded within the actuator itself, to external vision-based tracking-provide the necessary information to counteract these challenges. This data allows for real-time adjustments, enabling precise movements, adaptive behaviors, and safe interaction with unpredictable environments. Ultimately, sophisticated sensing isn’t merely an add-on, but a foundational element for transforming ERAs from promising prototypes into reliable and versatile robotic systems capable of complex tasks.

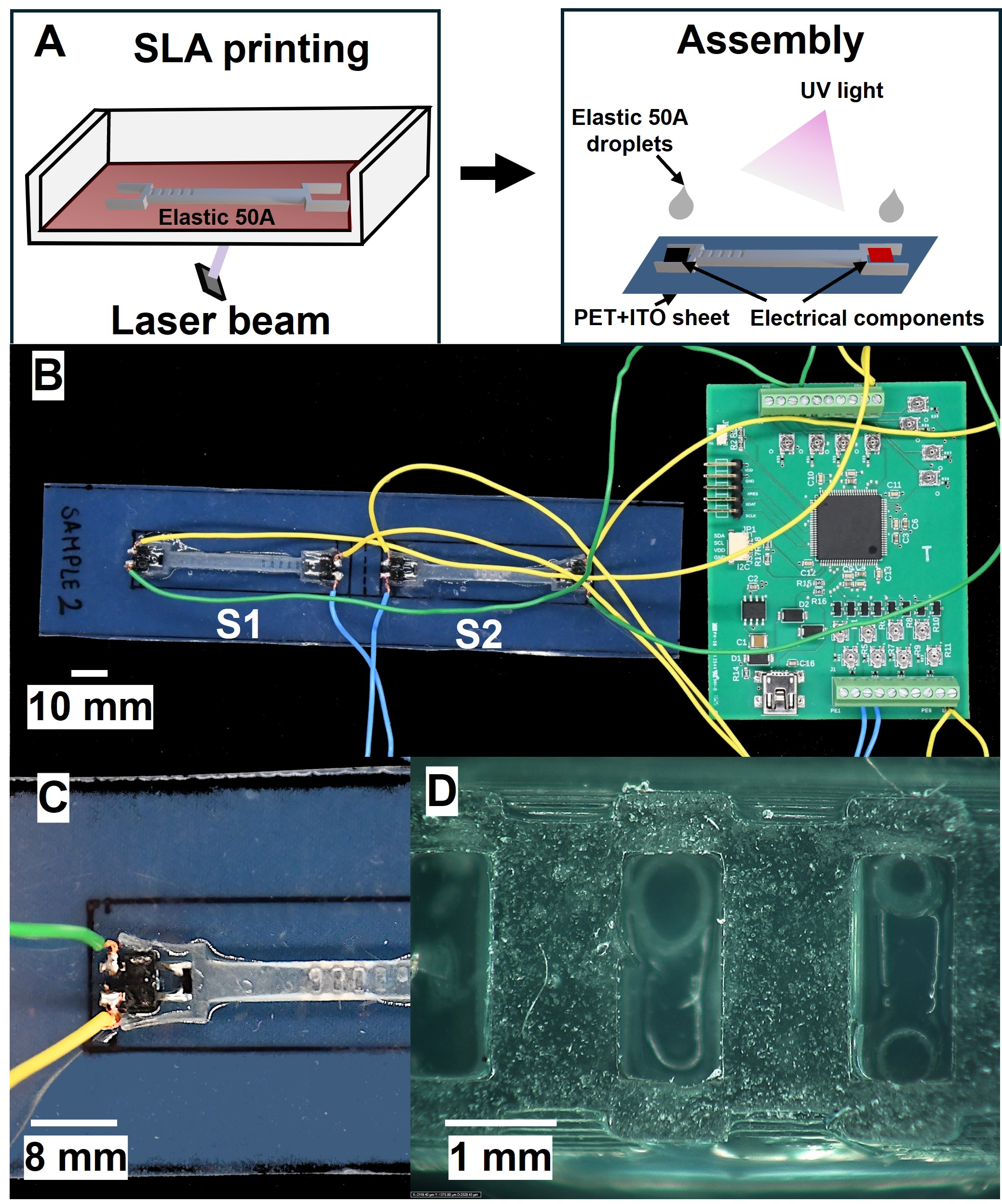

![The curvature of the electro-ribbon, measured during loading with an 8 kV voltage and 20 g mass over 51.75 mm, is sensed by soft optical sensors [latex]S_1[/latex] and [latex]S_2[/latex] positioned with emitters near the anchoring point and receivers in the distal clips.](https://arxiv.org/html/2602.17474v1/Figures/Figure_Curvature2.png)

Sensing the Unseen: Limitations of Conventional Methods

Traditional methods for measuring deformation in Electrically Reconfigurable Antennas (ERAs) often present integration challenges. Systems relying on Linear Variable Differential Transformers (LVDTs) or physical strain gauges introduce significant weight and volume, directly impacting the performance of lightweight ERA designs intended for applications like unmanned aerial vehicles. Furthermore, many conventional sensors utilize metallic components and active circuitry, generating electromagnetic interference that can disrupt the antenna’s operation and degrade signal quality. This interference necessitates additional shielding and filtering, adding further to the system’s complexity and weight. The size and electromagnetic signature of these sensors therefore limit the achievable miniaturization and performance of advanced ERA systems.

Capacitance-based sensing utilizes the change in capacitance between electrodes to determine ERA deformation, offering the advantage of integrating sensing functionality directly into the actuator structure-a “self-sensing” capability. However, this method is inherently susceptible to electrical noise from various sources, including temperature fluctuations, electromagnetic interference, and parasitic capacitances within the system. Consequently, meticulous calibration procedures are essential to establish a baseline and compensate for these error sources. Calibration typically involves applying known displacements and recording corresponding capacitance changes to create a mapping function, and may require frequent re-calibration to maintain accuracy due to sensor drift or environmental changes. Furthermore, signal conditioning and filtering techniques are often necessary to improve the signal-to-noise ratio and enhance measurement resolution.

Effective control of Electrically Reconfigurable Antennas (ERAs) necessitates a closed-loop control system to mitigate inherent mechanical instability and maintain desired performance characteristics. This system relies on continuous monitoring of ERA deformation and subsequent adjustments to applied control voltages. However, the efficacy of this control is directly proportional to the accuracy and reliability of the feedback signal; errors or noise within this feedback loop will propagate and exacerbate instability, potentially leading to degraded performance or even system failure. Consequently, sensor precision, calibration stability, and robust signal processing are critical components in ensuring the successful implementation of closed-loop control for ERAs.

Current electrorheological actuator (ERA) systems require deformation sensing for effective control, but traditional methods present limitations in size, weight, and electromagnetic interference. A new sensing paradigm is needed to address these issues and enable high-performance ERAs. This involves developing techniques capable of providing precise measurements of ERA deformation with minimal impact on the actuator’s dynamics. Ideal solutions would be lightweight, compact, and electromagnetically passive, allowing for real-time feedback without introducing external disturbances. Research focuses on modalities such as integrated micro-sensors, optical methods leveraging laser displacement or interferometry, and potentially self-sensing materials that directly correlate deformation with a measurable electrical property, offering improved accuracy and reduced system complexity.

Illuminating Movement: The Optically-Sensed ERA Solution

The Optically Sensorized Electro-Ribbon Actuator (OS-ERA) integrates flexible waveguides directly into its structure to measure bending. These waveguides function by altering the intensity of light transmitted through them as the actuator deforms; bending causes a change in the angle of light propagation within the waveguide, inducing refraction and a corresponding shift in light intensity. This optical sensing approach offers several advantages, including a minimal mass increase to the actuator – avoiding interference with dynamic performance – and immunity to electromagnetic interference, as light is used for measurement rather than electrical signals. The embedded nature of the waveguides also allows for distributed sensing along the length of the actuator, providing a detailed profile of deformation.

The OS-ERA system determines actuator deformation by analyzing changes in light intensity within integrated soft waveguides. Bending of the actuator alters the path of light traveling through these waveguides, inducing measurable variations in light intensity that correlate directly to the degree of curvature. To enhance accuracy and mitigate noise, a Butterworth filter is applied to the raw light intensity data. This filtering process removes high-frequency noise while preserving the signal indicative of actuator bending, enabling precise determination of deformation characteristics. The combination of optical sensing and signal processing allows for quantitative measurement of actuator shape and position.

A supervised machine learning approach was implemented to classify bending states of the OS-ERA, utilizing a Support Vector Machine (SVM) with a Radial Basis Function (RBF) kernel. This methodology achieved repeatable classification independent of applied voltage, demonstrating consistent performance even with a limited training dataset of only three trials. The SVM was trained to correlate changes in light intensity, as measured by the optical sensing system, with specific bending configurations of the actuator. The RBF kernel allows for non-linear mapping between input features and output classes, enabling accurate classification despite the complex relationship between actuator deformation and optical signal changes. This minimal training requirement highlights the efficiency and adaptability of the OS-ERA sensing system in conjunction with machine learning techniques.

Testing of the Optically Sensorized Electro-Ribbon Actuator (OS-ERA) revealed a measured contraction of 99.31% when subjected to loading conditions. This indicates a substantial degree of deformation capability within the actuator’s design. The reported percentage represents the amount of reduction in length from the actuator’s initial, unloaded state, demonstrating its ability to achieve significant shape changes in response to applied force. This high level of deformation is a key characteristic of the OS-ERA and contributes to its potential applications in areas requiring substantial mechanical adjustments.

![During OS-ERA movement ([latex]12.3 g, 5 kV[/latex]), the model accurately predicts actuator curves (visualized as colored ribbons) based on video frames, as demonstrated by the successful mapping of testing trajectories at 3 kV (blue) and 5 kV (red) onto training data from 4 kV (colored dots).](https://arxiv.org/html/2602.17474v1/Figures/Figure_Results.jpg)

Beyond Current Limits: The Expanding Horizon of Soft Robotics

Conventional sensing methods often struggle with the inherent compliance and infinite degrees of freedom characteristic of soft robots, hindering precise control and reliable operation. However, the development of the Optically-Sensed Elastic Resistance Amplifier (OS-ERA) offers a significant leap forward. This innovative sensing solution directly measures deformation within the soft robot’s structure using embedded optical sensors, providing a robust and accurate feedback mechanism. Unlike traditional methods reliant on external cameras or complex mathematical models, the OS-ERA is largely independent of external factors and offers high sensitivity, allowing for nuanced control of ERA-driven soft robots even under complex loading conditions. This improved sensing capability not only enhances the robot’s ability to perform intricate tasks but also paves the way for more sophisticated control strategies and ultimately, more adaptable and intelligent soft robotic systems.

The development of accurate and reliable soft robotic systems unlocks a spectrum of possibilities across multiple disciplines. In the realm of healthcare, the technology promises to revolutionize minimally invasive surgical procedures, allowing for greater precision and reduced trauma through flexible, adaptable tools. Beyond medicine, inspiration from biological systems – such as the movements of an octopus or the gait of a cheetah – fuels the creation of bio-inspired locomotion systems capable of navigating complex terrains. Furthermore, the nuanced control afforded by these robots enables the development of adaptive grasping mechanisms, which can delicately handle fragile objects or firmly secure tools, proving invaluable in manufacturing, search and rescue operations, and even everyday assistive devices.

The predictive power of lumped-parameter models for optimizing OS-ERA systems hinges on their continued refinement, particularly in accounting for the complex interplay between material properties and loading conditions. Current models, while effective, often simplify the inherent non-linearities present in soft robotic actuators; improved formulations incorporating more nuanced representations of elastomer behavior – including viscoelasticity and hysteresis – are crucial. Researchers are actively exploring methods to calibrate these models using data-driven approaches, allowing for accurate predictions of deformation and force output under a wider range of external loads and environmental factors. This enhanced predictive capability isn’t merely about improving accuracy; it directly enables the design of more robust and adaptable soft robots capable of performing complex tasks in unpredictable real-world scenarios, and facilitates the development of control strategies that maximize performance and minimize energy expenditure.

Continued development hinges on a synergistic approach, pairing the OS-ERA sensing technology with sophisticated control algorithms – such as reinforcement learning and model predictive control – to enable increasingly complex and autonomous movements in soft robots. Simultaneously, investigations into novel materials – including intrinsically stretchable polymers and self-healing elastomers – promise to overcome current limitations in durability, responsiveness, and payload capacity. This convergence of intelligent control and advanced materials will not only refine existing applications in fields like minimally invasive surgery and bio-inspired robotics, but also unlock entirely new possibilities, potentially leading to adaptable prosthetics, personalized rehabilitation devices, and even soft robots capable of navigating and interacting with unstructured environments in unprecedented ways.

The pursuit of accurate proprioception in soft robotics, as demonstrated by this work on optically sensorized electro-ribbon actuators, echoes a fundamental principle of intelligence: understanding through decomposition. The researchers didn’t simply accept the limitations of sensing bending states; instead, they meticulously reverse-engineered the problem with integrated optical waveguides and machine learning. As Marvin Minsky once stated, “You can’t always get what you want, but if you try sometimes you find you can get what you need.” This sentiment beautifully encapsulates the iterative process of scientific discovery; the team needed a precise understanding of curvature, and through ingenious design and analysis, they achieved it, highlighting that progress often resides in challenging existing boundaries.

Where Do We Go From Here?

The presented work circumvents a persistent challenge in electro-ribbon actuator (ERA) control – the elusive sense of self. The integration of optical sensing, while demonstrably effective at classifying bending states, merely scratches the surface of what ‘proprioception’ might mean for a fundamentally deformable machine. Current machine learning models excel at pattern recognition, but true understanding demands a system that anticipates failure, not just reacts to it. The actuator, in essence, still requires external validation of its own state-a frustrating reliance on observation for a device striving for autonomous movement.

Future iterations will inevitably push the boundaries of materials science. The dielectric liquid zipping mechanism, while elegant, represents a potential single point of failure. A more robust design might explore self-healing polymers or redundant actuation pathways. More intriguing, however, is the prospect of embedding computational elements within the actuator itself. Imagine an ERA that not only senses its deformation but also adjusts its internal parameters to compensate for wear, environmental changes, or even intentional damage – a system that learns, adapts, and arguably, survives.

The real test won’t be achieving increasingly accurate curvature analysis, but in relinquishing control altogether. Can an ERA, armed with a sufficiently sophisticated internal model, navigate complex environments without explicit guidance? The answer, predictably, lies in embracing the inevitable chaos of the physical world – for it is in the struggle against entropy that true intelligence, even mechanical intelligence, is forged.

Original article: https://arxiv.org/pdf/2602.17474.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- MLBB x KOF Encore 2026: List of bingo patterns

- eFootball 2026 Jürgen Klopp Manager Guide: Best formations, instructions, and tactics

- Overwatch Domina counters

- 1xBet declared bankrupt in Dutch court

- Gold Rate Forecast

- Magic Chess: Go Go Season 5 introduces new GOGO MOBA and Go Go Plaza modes, a cooking mini-game, synergies, and more

- eFootball 2026 Starter Set Gabriel Batistuta pack review

- Clash of Clans March 2026 update is bringing a new Hero, Village Helper, major changes to Gold Pass, and more

- Brawl Stars Brawlentines Community Event: Brawler Dates, Community goals, Voting, Rewards, and more

- eFootball 2026 Show Time Worldwide Selection Contract: Best player to choose and Tier List

2026-02-22 18:03