Author: Denis Avetisyan

A new framework translates natural language instructions into executable manufacturing plans, promising more adaptable and intelligent production systems.

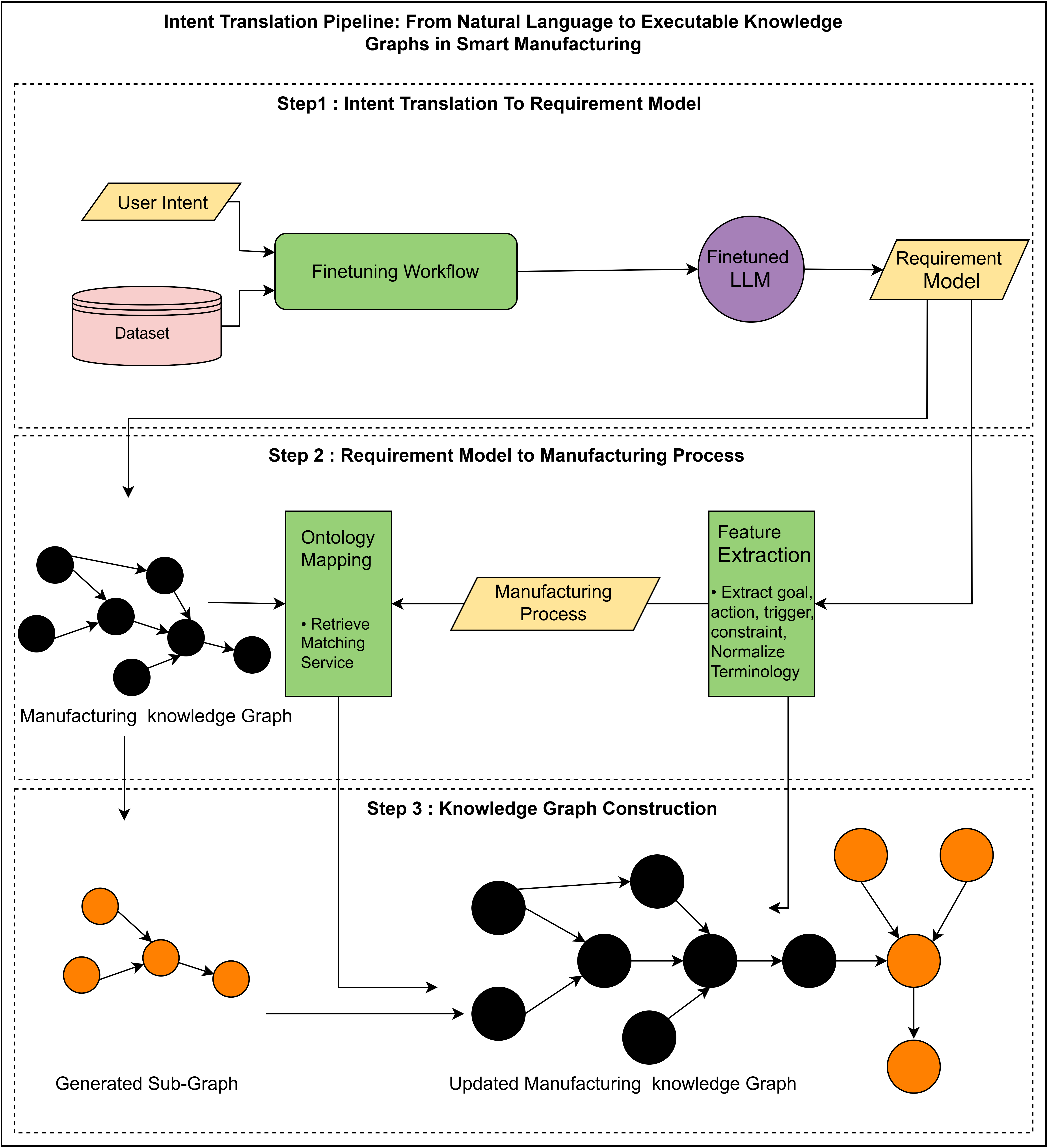

This review details a unified approach leveraging instruction-tuned large language models and knowledge graphs to model manufacturing requirements based on the ISA-95 standard.

The increasing complexity of modern manufacturing demands more flexible and intuitive interfaces between human operators and automated systems. This need is addressed in ‘Intent-Driven Smart Manufacturing Integrating Knowledge Graphs and Large Language Models’ which introduces a unified framework leveraging instruction-tuned large language models and knowledge graphs to translate natural language manufacturing intents into structured, machine-executable requirement models. Experimental results demonstrate significant performance gains, achieving up to 97.27% overall accuracy in intent translation, paving the way for scalable and adaptive manufacturing processes. Could this approach unlock a new era of truly intelligent and human-centric manufacturing systems?

Deconstructing the Factory Floor: The Knowledge Bottleneck

The advent of Industry 4.0 is fueling a transformation in manufacturing, promising gains in automation and efficiency previously considered unattainable. This new paradigm leverages technologies like the Internet of Things, cloud computing, and artificial intelligence to create ‘smart’ factories capable of self-optimization and real-time decision-making. By connecting machines, systems, and data across the entire production lifecycle, manufacturers envision streamlined processes, reduced waste, and increased productivity. This isn’t merely about automating existing tasks; it’s about creating adaptive, responsive systems that can anticipate problems, adjust to changing conditions, and ultimately, drive innovation at an accelerated pace. The potential impact extends beyond cost savings, encompassing enhanced product quality, faster time-to-market, and the ability to personalize products to meet individual customer needs.

The promise of smart manufacturing hinges on the ability of systems to not just collect data, but to interpret it and make informed decisions-a task proving remarkably difficult. Current knowledge representation methods often fall short when faced with the sheer complexity and dynamic nature of modern manufacturing environments. Effectively capturing the nuanced relationships between machines, materials, processes, and products-and then reasoning about them in real-time-requires moving beyond simple data aggregation. The challenge lies in creating systems that can understand context, handle uncertainty, and adapt to unforeseen circumstances – essentially, systems capable of ‘common sense’ reasoning within a highly specialized domain. Without breakthroughs in this area, the full potential of Industry 4.0 will remain unrealized, as automation will be limited by an inability to navigate the inherent complexities of the manufacturing floor.

Conventional manufacturing intelligence systems often falter when confronted with the sheer variety and velocity of data generated in modern facilities. These systems, typically reliant on pre-programmed rules and static datasets, struggle to synthesize information from disparate sources – sensor readings, machine logs, quality control reports, and even operator notes – creating knowledge silos that limit their effectiveness. This inability to dynamically integrate and interpret evolving data streams prevents true autonomy; the systems cannot readily adapt to changing production conditions, unexpected equipment behavior, or the introduction of new processes. Consequently, human intervention remains crucial for problem-solving and optimization, negating the full potential of smart manufacturing and hindering the development of genuinely self-regulating production lines.

Mapping the Machine: Knowledge Graphs as the Foundation

Knowledge Graphs (KGs) provide a formalized method for representing information about a specific domain – such as manufacturing processes, equipment, or materials – in a way that computers can directly process. This representation moves beyond simple data storage by explicitly defining entities – the key objects or concepts – and the relationships between them. The machine-interpretable format allows for automated reasoning; that is, the KG can be used to infer new knowledge based on existing data and defined rules. For example, a KG could determine that a specific machine requires maintenance based on its operational hours and the defined maintenance schedule for that equipment type. This capability extends beyond simple data retrieval to support predictive analytics, anomaly detection, and optimization within a manufacturing environment.

Knowledge Graphs (KGs) enable data integration by representing information as interconnected entities and relationships, rather than isolated data points. This structure allows data from disparate sources – such as PLCs, MES, ERP, and sensor data – to be linked based on shared entities or properties. By defining these relationships, KGs overcome data silos and facilitate complex queries that require combining information across multiple systems. For example, a query could identify all work orders impacted by a specific equipment failure, linking failure data from a sensor, the affected equipment from the asset management system, and the related work orders from the MES. The graph structure supports traversal and inference, enabling answers to questions that would be difficult or impossible to resolve with traditional relational databases.

The ISA-95 standard, also known as IEC 62453, provides a hierarchical model for manufacturing operations management, defining levels from enterprise resource planning (ERP) down to process control. Leveraging ISA-95 as a foundational framework for Knowledge Graph (KG) construction ensures semantic consistency and interoperability by establishing a common vocabulary and structure for representing manufacturing entities – such as equipment, materials, personnel, and processes – and their relationships. Specifically, ISA-95’s defined levels and functional areas serve as a blueprint for organizing KG nodes and edges, facilitating data exchange and integration across disparate systems within the manufacturing environment. This adherence to a recognized standard simplifies KG maintenance, promotes reusability of knowledge assets, and reduces the complexity of integrating new data sources.

Graph databases, such as Neo4j, are frequently employed for the storage and management of knowledge graph data due to their native support for representing and traversing relationships. Unlike relational databases which require complex joins to navigate connections, graph databases store relationships as first-class citizens, enabling significantly faster query performance for connected data. Neo4j, specifically, utilizes a property graph model, allowing both nodes (entities) and relationships to have properties, which facilitates the representation of rich, contextual information. This architecture is particularly well-suited for knowledge graphs where the connections between data points are as important as the data itself, supporting efficient reasoning and inference operations critical for intelligent manufacturing applications.

Bridging the Gap: LLMs and KGs for Intent-Driven Automation

Large Language Models (LLMs) demonstrate proficiency in natural language processing tasks, specifically excelling at understanding the semantic meaning of text and accurately identifying user intent from unstructured input. However, these models are fundamentally pattern recognition systems trained on extensive text corpora and, as such, lack the capacity for deductive or inductive reasoning. While LLMs can simulate reasoning through learned associations, they cannot perform complex logical inferences or reliably apply knowledge beyond the data they were trained on. This limitation necessitates the integration of LLMs with external knowledge sources and reasoning engines to enable true intent-driven automation requiring more than simple pattern matching.

The integration of Large Language Models (LLMs) with Knowledge Graphs (KGs) facilitates the conversion of unstructured natural language queries into structured, machine-readable formats. This process leverages the LLM’s capacity for natural language understanding to identify key entities and relationships within a query, and then maps these to corresponding nodes and edges within the KG. The resulting structured representation enables automated reasoning by allowing systems to traverse the KG, infer new information, and ultimately support decision-making processes that would be impossible with natural language alone. This approach moves beyond simple keyword matching, allowing for nuanced understanding and complex query resolution based on the relationships defined within the KG.

Methods such as Multi-State LSTMs (MS-LSTM) and frameworks like Knowledge-Aware Reasoning Machine (KARMA) address the challenge of grounding natural language in structured knowledge. MS-LSTM employs a recurrent neural network architecture to model the sequential aspects of language while simultaneously tracking the state of entities within a knowledge graph (KG), enabling it to identify and link linguistic expressions to corresponding KG entities. KARMA, conversely, focuses on explicitly representing knowledge graph traversals as part of the reasoning process, allowing the system to not only identify entities but also to infer relationships and derive new knowledge based on the KG structure. Both approaches utilize techniques like entity linking and relation extraction to map natural language input to a formal KG representation, thereby facilitating semantic understanding and enabling downstream tasks like question answering and automated reasoning.

Instruction Tuning significantly improves the capacity of Large Language Models (LLMs) to produce JSON Requirement Models from natural language input. Evaluations demonstrate an accuracy rate of 97.29% in converting user intents into structured, machine-executable models. This process exhibits a rapid inference time of 54 milliseconds per sample, indicating suitability for real-time applications requiring the translation of natural language requests into actionable instructions for automated systems. The methodology focuses on refining the LLM’s output format to adhere to a predefined JSON schema, ensuring compatibility with downstream processing and execution engines.

Beyond Automation: Servitization and Manufacturing-as-a-Service

The convergence of knowledge graphs (KGs) and large language models (LLMs) signifies a fundamental shift in manufacturing, driving a transition from traditional product sales to service-oriented models known as servitization. This isn’t merely about offering extended warranties; it’s about delivering manufacturing capabilities as a flexible, on-demand service. KGs provide a structured, machine-readable representation of complex manufacturing processes, equipment data, and domain expertise, while LLMs unlock the ability to reason over that knowledge, predict potential issues, and personalize service offerings. By integrating these technologies, manufacturers can move beyond simply selling a product and instead offer ongoing performance, optimization, and proactive maintenance – essentially selling ‘outcome as a service’ and forging deeper, more valuable relationships with their customers. This paradigm represents a move from ownership to access, fostering innovation and creating new revenue streams within the manufacturing sector.

Manufacturing-as-a-Service represents a fundamental shift in how production is approached, moving beyond the traditional model of selling physical products to offering access to manufacturing capabilities as a fully flexible, on-demand service. This paradigm allows businesses to scale production rapidly without significant capital investment, accessing specialized equipment, expertise, and processes precisely when needed. Rather than owning and maintaining costly infrastructure, companies can effectively ‘rent’ manufacturing capacity, optimizing resource utilization and fostering greater agility in response to fluctuating market demands. This service-oriented approach extends beyond simple outsourcing; it involves a continuous, data-driven relationship where manufacturers provide not just parts, but also insights, predictive maintenance, and process optimization – ultimately delivering performance as a service and fostering deeper customer engagement.

The realization of sophisticated Manufacturing-as-a-Service hinges on robust knowledge representation, and advanced Knowledge Graph (KG) construction frameworks are proving essential to this endeavor. Tools like OmEGa and KG-LLM facilitate the creation of richly interconnected KGs, capturing not just product data but also process knowledge, maintenance schedules, and even real-time performance metrics. However, building a KG is not a one-time task; methods such as Rethink provide iterative approaches to KG refinement, ensuring the knowledge remains accurate and current as manufacturing processes evolve. These frameworks enable automated reasoning and intelligent decision-making, allowing manufacturers to move beyond simply selling products to offering comprehensive, data-driven services, ultimately transforming how value is created and delivered.

The application of knowledge graphs (KGs) is proving transformative in complex maintenance regimes, as exemplified by the Aircraft Maintenance Prediction Optimization (AMPO) framework. AMPO leverages a meticulously constructed KG to integrate diverse data sources – including maintenance records, sensor readings, and engineering specifications – into a unified, queryable resource. This allows for not only predictive maintenance, identifying potential failures before they occur, but also for optimized scheduling of repairs and streamlined parts ordering. By reasoning over the relationships within the KG, AMPO can suggest the most effective repair procedures, identify root causes of failures with greater accuracy, and ultimately reduce downtime and operational costs within the aviation industry. This demonstrates the practical power of KGs to move beyond simple data storage, enabling intelligent decision-making and a proactive approach to asset management.

The Future of Intelligent Manufacturing: A Knowledge-Driven Ecosystem

The convergence of knowledge graphs (KGs) and large language models (LLMs) signifies more than incremental progress in manufacturing; it establishes the foundation for a fundamentally new ecosystem driven by accessible and actionable knowledge. Traditionally, manufacturing relied on siloed data and implicit expertise, limiting adaptability and innovation. This new paradigm shifts that reliance, enabling systems to not just process data, but to understand the relationships between components, processes, and market forces. By representing manufacturing knowledge in a structured, interconnected format – the KG – and then empowering LLMs to reason over that knowledge, manufacturers can achieve unprecedented levels of automation, predictive maintenance, and rapid response to disruption. This isn’t simply about building smarter machines; it’s about creating a self-learning, self-optimizing manufacturing environment where knowledge, rather than physical assets, is the primary driver of value.

The emerging manufacturing landscape promises a dynamic system distinguished by its capacity to swiftly adjust to evolving conditions. This isn’t simply about reacting to change, but proactively anticipating and incorporating new information – from supply chain disruptions to shifting consumer preferences – with minimal friction. A knowledge-driven ecosystem empowers manufacturers to reconfigure processes, redeploy resources, and even redesign products on-the-fly, fostering remarkable resilience against unforeseen challenges. This heightened responsiveness translates directly into a competitive advantage, enabling businesses to not only survive but thrive amidst constant market flux and deliver increasingly personalized customer experiences.

Manufacturers are poised to redefine operational paradigms by strategically harnessing the power of integrated knowledge systems. Beyond simple automation, a knowledge-centric approach enables proactive problem-solving, predictive maintenance, and the optimization of complex processes – ultimately driving significant gains in efficiency and reducing waste. This isn’t merely about processing data, but about understanding why things happen, allowing for rapid adaptation to unforeseen challenges and the swift implementation of innovative solutions. Consequently, manufacturers can move beyond reactive strategies to anticipate customer needs, personalize products with unprecedented precision, and deliver enhanced value that fosters lasting relationships and competitive advantage. The ability to synthesize information from diverse sources, combined with advanced reasoning capabilities, will be the cornerstone of future manufacturing success.

The progression of intelligent manufacturing hinges significantly on ongoing investigation into knowledge distillation and the refinement of advanced reasoning algorithms. Knowledge distillation focuses on transferring expertise from complex, potentially unwieldy knowledge graphs to smaller, more efficient models, enabling real-time decision-making on the factory floor. Simultaneously, breakthroughs in reasoning – moving beyond simple pattern recognition to causal inference and predictive analytics – will allow systems to not only identify problems but also proactively suggest and implement solutions. These combined efforts promise to unlock the latent potential within manufacturing data, fostering systems capable of continuous learning, autonomous optimization, and remarkably adaptable production processes, ultimately defining a new era of industrial intelligence.

The pursuit of intent-driven smart manufacturing, as detailed in this framework, inherently necessitates a willingness to deconstruct established processes. It’s a systematic probing of what is to reveal what could be. This echoes John McCarthy’s sentiment: “It is better to risk making a mistake than to be paralyzed by indecision.” The paper’s methodology – translating natural language into executable requirement models – isn’t simply about automation; it’s about actively testing the boundaries of current manufacturing limitations. Each translation is, in effect, a controlled experiment, a deliberate attempt to see if the system can accommodate a new intent. The elegance lies in the structured failure; identifying where the system resists allows for refinement and a deeper understanding of its underlying architecture, a confession of design sins, as it were.

Beyond the Blueprint

The presented framework, while a demonstrable step toward intent-driven manufacturing, skirts the inevitable question of trust. Translating natural language into executable models necessitates a system that not only understands intent but also rigorously verifies it. The current reliance on instruction tuning, however sophisticated, remains fundamentally a pattern-matching exercise. True intelligence demands the ability to identify not just what is said, but what is not said-the implicit assumptions, the potential failure modes, the unstated consequences.

Further exploration must confront the brittleness inherent in knowledge graph construction. Maintaining a consistently accurate and comprehensive representation of a manufacturing environment-especially one subject to constant change-is a Sisyphean task. The challenge isn’t merely data integration; it’s establishing a dynamic, self-correcting knowledge base capable of accommodating ambiguity and contradiction. The ISA-95 standard provides a useful scaffolding, but formal ontologies, by their nature, struggle to capture the messiness of real-world operations.

Ultimately, the pursuit of intent-driven manufacturing isn’t about replacing human expertise; it’s about augmenting it. The most fruitful avenue for future research lies not in automating decision-making entirely, but in building systems that transparently reveal their reasoning, allowing human operators to challenge, refine, and ultimately own the intelligence embedded within the manufacturing process. Security, after all, isn’t found in a black box, but in complete and utter visibility.

Original article: https://arxiv.org/pdf/2602.12419.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- MLBB x KOF Encore 2026: List of bingo patterns

- Overwatch Domina counters

- Honkai: Star Rail Version 4.0 Phase One Character Banners: Who should you pull

- eFootball 2026 Starter Set Gabriel Batistuta pack review

- Brawl Stars Brawlentines Community Event: Brawler Dates, Community goals, Voting, Rewards, and more

- Lana Del Rey and swamp-guide husband Jeremy Dufrene are mobbed by fans as they leave their New York hotel after Fashion Week appearance

- Gold Rate Forecast

- Breaking Down the Ending of the Ice Skating Romance Drama Finding Her Edge

- ‘Reacher’s Pile of Source Material Presents a Strange Problem

- Top 10 Super Bowl Commercials of 2026: Ranked and Reviewed

2026-02-17 05:20