Author: Denis Avetisyan

A new robotic system demonstrates the ability to strategically manipulate objects and pack them into partially filled containers, opening doors for automation in unstructured environments.

Researchers achieve a 70% success rate using physics-based simulation, trajectory optimization, and model predictive control for non-prehensile object packing.

Automating warehouse tasks demands increasingly sophisticated robotic manipulation, yet current bin-packing strategies largely presume empty containers, ignoring the reality of cluttered environments. This paper, ‘Pack it in: Packing into Partially Filled Containers Through Contact’, introduces a robotic system that overcomes this limitation by strategically manipulating existing objects to create space for new items. Achieving a 70% success rate on real hardware, the approach utilizes contact-aware trajectory optimization within a model predictive control framework, guided by a physics-aware perception system. Could this contact-based method unlock truly autonomous and efficient warehouse operations, even in highly disorganized settings?

The Inherent Disorder of Real-World Bin Packing

Robotic bin packing, a deceptively complex task for automated systems, consistently falters when moved beyond carefully curated laboratory settings. The primary difficulty lies in the inherent unpredictability of real-world environments-spaces are rarely neat and orderly. Objects tend to be irregularly shaped, varying widely in size, weight, and fragility, and are often partially hidden from view-a phenomenon known as occlusion. This poses a significant challenge for robotic perception systems, which rely on visual data to identify and locate objects. Consequently, traditional algorithms, designed for simpler scenarios, struggle to accurately assess available space and plan collision-free paths, leading to inefficiencies and failures when confronted with the clutter and complexity of a densely populated bin or storage area.

Automated bin packing in realistic environments presents a significant hurdle for robotics due to limitations in reliably perceiving, planning, and executing complex manipulations. Current systems struggle with the ambiguity of cluttered scenes, often misidentifying object shapes and available free space, leading to flawed plans. These plans frequently fail during execution because they don’t account for the subtle dynamics of contact – the way objects shift and settle when touched – or unexpected disturbances. Consequently, robotic attempts at packing can result in unstable arrangements, object detachment, and ultimately, task failure, highlighting the need for more sophisticated algorithms capable of handling the inherent uncertainties of real-world clutter and ensuring robust, dependable performance.

Successfully packing objects into a confined space isn’t simply a matter of finding room; it demands intricate calculations regarding available volume and the potential for interference. The challenge lies in a robot’s ability to not only perceive the shapes and sizes of items, but also to anticipate how those objects will interact with each other and the container walls during placement. This necessitates a constant evaluation of ‘free space’ – areas not currently occupied – while simultaneously predicting collisions and modeling the physics of contact. Each object introduced alters the available space and the stability of the existing arrangement, creating a cascading effect of dependencies that requires complex computational strategies to resolve in real-time. Effectively navigating these dynamics is crucial, as even minor miscalculations can lead to instability, object detachment, or complete task failure.

Automated bin-packing systems frequently encounter difficulties not present in controlled laboratory settings, leading to operational failures stemming from unpredictable real-world factors. These systems are particularly susceptible to object detachment-where items are inadvertently dislodged during manipulation-and task timeouts, occurring when the robot is unable to complete the packing process within a reasonable timeframe. The root cause lies in the inherent variability of cluttered environments: unexpected object geometries, inconsistent friction coefficients, and subtle disturbances all contribute to inaccurate predictions during motion planning. Consequently, even minor deviations from anticipated conditions can cascade into larger errors, forcing the system to halt or causing items to fall, highlighting the need for more robust and adaptable algorithms capable of handling the complexities of genuine, unstructured spaces.

![The optimal packing pose minimizes disturbance to surrounding objects, as shown on the top, while suboptimal poses, like the one on the bottom, incur a higher cost [latex]Eq.5[/latex] due to their inability to properly displace objects within the container.](https://arxiv.org/html/2602.12095v1/Placement_planner_snapshots.png)

A Physics-Informed System for Non-Prehensile Manipulation

Non-prehensile manipulation, as employed in this system, refers to the insertion of objects into a container without directly grasping and lifting them. This technique utilizes pushing, sliding, or other forms of external force application to maneuver objects into desired positions. This approach is particularly advantageous in cluttered environments where traditional grasping-based robotic systems struggle due to limited access or potential collisions with surrounding objects. By avoiding the need for a secure grip, the system can operate effectively in scenes with high object density and complex geometries, offering increased robustness and operational flexibility compared to methods reliant on prehensile actions.

The system’s perception module estimates the 6D pose of objects – position and orientation – using a combined vision and physics-based approach. This module integrates data from visual sensors with predictions derived from a physics engine to improve pose estimation accuracy, particularly when objects are partially occluded. By modeling physical properties and anticipating likely configurations based on observed contact points and gravitational forces, the system can resolve ambiguities in the visual data and infer the complete pose even with limited visibility. This predictive capability allows for robust tracking and manipulation in complex, cluttered environments where traditional vision-only methods would fail.

The perception system employs marker-based tracking utilizing OptiTrack Vicon motion capture technology to determine the six-degrees-of-freedom pose – position and orientation – of objects within the workspace. Specifically, objects are fitted with passive infrared markers which are detected by OptiTrack cameras. The system then triangulates the 3D locations of these markers, enabling accurate, real-time pose estimation even with partial occlusions. This approach yields position accuracy of less than one millimeter and orientation accuracy of less than one degree, providing the necessary precision for subsequent path planning and manipulation stages. Data is outputted as a stream of pose information, synchronized with the robot’s control loop.

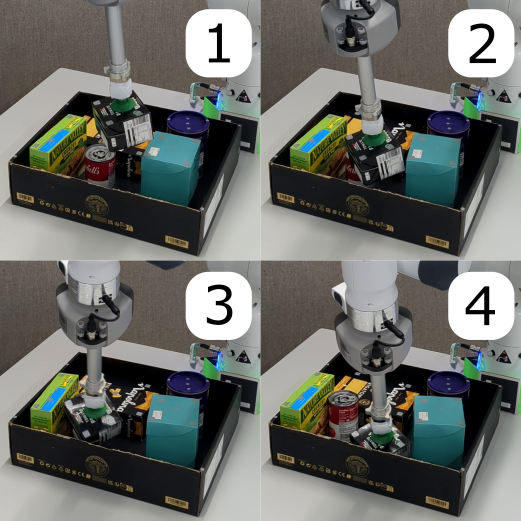

The placement planner operates by simulating proposed object poses within the container environment to assess feasibility prior to execution. This simulation incorporates a physics engine to model contact forces and predict resulting object and container stability. Collision detection is performed to identify potential interferences between the object being placed and both existing packed objects and the container walls, preventing invalid placements. The planner evaluates multiple potential poses, scoring them based on stability metrics and collision-free operation, and selects the highest-scoring pose for robotic execution. This proactive approach minimizes the need for corrective actions during physical packing and ensures robust performance in dynamic environments.

Trajectory Optimization: A Mathematically Precise Approach

Trajectory optimization is utilized to transform the task of packing objects into a mathematical problem suitable for robotic control. This involves defining a cost function that quantifies both the efficiency of the packing arrangement – typically maximizing the number of objects placed – and the probability of successful placement, thereby minimizing potential failures due to collisions or unstable configurations. The robot’s movements are then planned as a sequence of states and control inputs that minimize this cost function, subject to the robot’s kinematic and dynamic constraints. By formally defining the packing problem in this manner, we enable the use of optimization algorithms to automatically generate efficient and robust motion plans.

The Iterative Linear Quadratic Regulator (iLQR) algorithm is employed to address the non-linear optimization problem inherent in trajectory planning for robotic insertion. iLQR functions by locally approximating the system dynamics with a linear model and iteratively refining a trajectory based on quadratic cost functions that penalize deviations from the desired path and control effort. This iterative process involves computing a locally optimal control law using a Riccati equation, followed by trajectory updates and re-linearization. The resulting trajectories are characterized by smoothness and dynamic feasibility, ensuring that the robot can physically execute the planned movements within its kinematic and dynamic limits. The algorithm’s efficiency stems from its ability to leverage second-order information, enabling rapid convergence to optimal solutions for complex, multi-dimensional problems.

Physics simulation is integral to the trajectory optimization process, enabling prediction of contact interactions between the robot and the environment during insertion. These simulations utilize dynamic models to forecast forces and torques arising from contact, identifying potential collision scenarios or instability issues before execution. By simulating these interactions, the planned trajectory can be refined to maintain stable contact, minimize stress on the robot, and avoid failures due to unforeseen physical constraints. Specifically, simulation data informs adjustments to trajectory waypoints, velocity profiles, and applied forces, increasing the robustness of the insertion process against modeling errors and external disturbances.

Model Predictive Control (MPC) functions by repeatedly solving an optimization problem over a finite time horizon during the robot’s insertion process. At each control step, MPC utilizes the current state of the system, a dynamic model, and predicted disturbances to calculate an optimal trajectory for the upcoming time interval. This trajectory is then applied to the robot, and the process repeats, shifting the prediction horizon forward. This continuous re-optimization allows the system to react to unmodeled dynamics, external disturbances, and inaccuracies in the robot’s state estimation, ensuring robust and successful insertion even in the presence of uncertainty. The optimization considers constraints such as robot joint limits, collision avoidance, and desired insertion force profiles.

Demonstrated Robustness and Pathways for Future Advancement

The system exhibits markedly improved reliability in non-prehensile manipulation tasks, substantially lowering the incidence of operational failures. Traditional robotic approaches often struggle with both applying appropriate force and maintaining secure contact with objects during insertion, leading to either insufficient force for effective manipulation or unintended detachment. This framework mitigates these issues through precise reasoning about physical interactions and environmental constraints, allowing for a more controlled and stable insertion process. By proactively anticipating and addressing potential failure points, the system minimizes disruptions and significantly enhances the consistency of object placement, even within densely cluttered containers.

The system’s ability to reliably insert objects into cluttered containers hinges on its sophisticated understanding of available space and potential for collision. Unlike conventional robotic manipulation techniques that often rely on simplified models or pre-defined trajectories, this framework meticulously analyzes the environment to predict how an object will interact with both the container and any existing contents. By proactively identifying and avoiding potential collisions before they occur, the system circumvents a common source of failure in non-prehensile manipulation – the lodging or displacement of objects during insertion. This proactive collision avoidance, combined with precise free-space reasoning, allows for successful manipulation even in densely packed and unpredictable environments, representing a significant advancement over methods prone to getting stuck or causing unintended disturbances.

The developed framework exhibits a remarkable capacity to generalize across diverse scenarios, extending beyond the specific objects and containers used during its initial training phase. This adaptability stems from the system’s reliance on physics-based planning and free-space reasoning, allowing it to effectively manipulate novel objects with varying geometries and material properties. Furthermore, the framework isn’t constrained by specific container dimensions or configurations; it successfully navigates and inserts objects into receptacles of different shapes, sizes, and levels of clutter. This inherent flexibility positions the system as a versatile solution for a broad spectrum of robotic manipulation tasks, promising reliable performance in dynamic and unpredictable environments where pre-programmed solutions often fall short.

The system’s performance showcases a compelling bridge between simulation and real-world applicability, achieving a 70% success rate when tested on physical robotic hardware. This demonstrates the feasibility of manipulating objects into cluttered containers without relying on traditional grasping methods, instead leveraging non-prehensile manipulation guided by physics-based planning. Notably, simulations yielded an even higher success rate of 93%, suggesting a strong correlation between the virtual and physical executions and highlighting the potential for further refinement through continued simulation-based optimization. The gap between simulated and real-world results, while present, remains narrow enough to validate the core principles of the approach and encourage its deployment in complex, unstructured environments.

The pursuit of efficient packing, as demonstrated in this work, echoes a fundamental principle of mathematical elegance. The system’s success isn’t merely about achieving a 70% packing rate, but about the provable logic underpinning the trajectory optimization and physics-based simulation. Donald Davies once stated, “The best programs are those that are elegantly simple.” This sentiment aligns perfectly with the research; the system avoids brute-force approaches, instead employing strategic contact-based manipulation to create space-a solution rooted in necessity and symmetry. The algorithm’s ability to predictably alter the container’s state, while impressive on hardware, is ultimately a testament to the mathematical purity driving its design.

What’s Next?

The reported 70% success rate, while demonstrating a functional system, merely shifts the focus. It is not enough to achieve packing; a rigorous analysis of the 30% failure cases is paramount. These failures are not random noise, but rather expose the limits of the current model – the points where the approximations of physics diverge from reality. To claim true progress, the system must offer a quantifiable metric of its own uncertainty – a prediction of when it cannot reliably pack, rather than simply attempting and failing.

Furthermore, the reliance on trajectory optimization, while computationally effective, begs the question of optimality. Does the system find the most efficient packing arrangement, or merely a sufficient one? A mathematically provable guarantee of optimality, even for a limited class of objects and containers, would elevate this work beyond empirical demonstration. To simply observe success on hardware does not validate the underlying principles.

Future work should therefore prioritize formal verification. Can the system’s behavior be reduced to a set of logical statements, allowing for automated proof of correctness? The pursuit of robust, provably correct robotic manipulation, rather than simply ‘good enough’ performance, remains the ultimate, and stubbornly elusive, goal.

Original article: https://arxiv.org/pdf/2602.12095.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Star Wars Fans Should Have “Total Faith” In Tradition-Breaking 2027 Movie, Says Star

- Gold Rate Forecast

- Christopher Nolan’s Highest-Grossing Movies, Ranked by Box Office Earnings

- Jessie Buckley unveils new blonde bombshell look for latest shoot with W Magazine as she reveals Hamnet role has made her ‘braver’

- Country star Thomas Rhett welcomes FIFTH child with wife Lauren and reveals newborn’s VERY unique name

- eFootball 2026 is bringing the v5.3.1 update: What to expect and what’s coming

- Mobile Legends: Bang Bang 2026 Legend Skins: Complete list and how to get them

- Decoding Life’s Patterns: How AI Learns Protein Sequences

- Are Halstead & Upton Back Together After The 2026 One Chicago Corssover? Jay & Hailey’s Future Explained

- KAS PREDICTION. KAS cryptocurrency

2026-02-15 16:03