Author: Denis Avetisyan

Researchers have developed a unified approach to modeling and controlling the complex interactions between robots and objects, paving the way for more robust and adaptable manipulation capabilities.

This work introduces Unicomp, a complementarity programming-based framework for real-time rigid-body manipulation, enabling handling of non-convex contacts and complex friction without predefined contact modes.

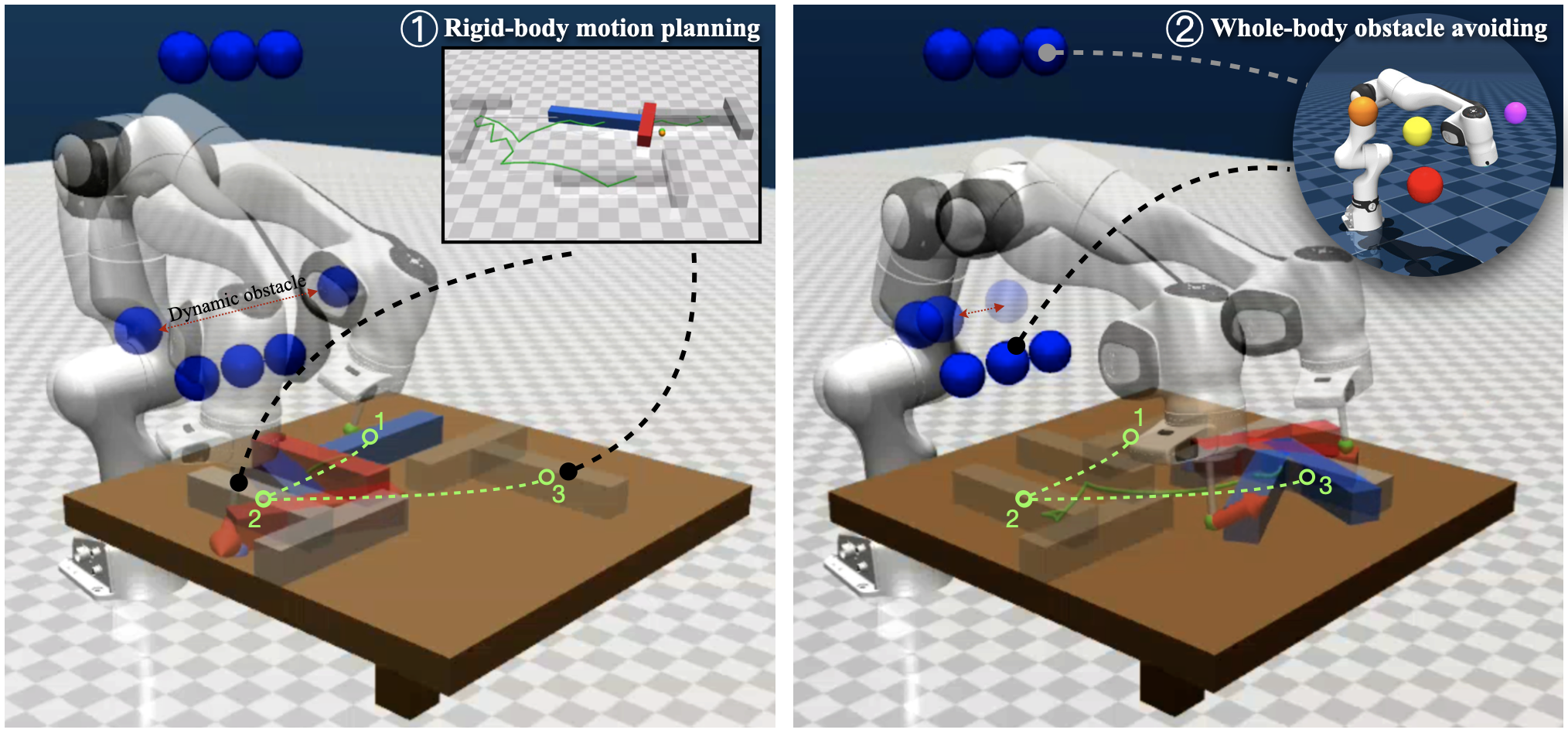

Robust robotic manipulation in cluttered environments demands planners reconcile free-space motion with sustained contact, yet existing approaches often simplify contact or struggle with transitions between contact modes. This paper introduces ‘A Unified Complementarity-based Approach for Rigid-Body Manipulation and Motion Prediction’, presenting Unicomp-a novel framework that models both free and contact dynamics within a single complementarity-based formalism. By representing interactions as coupled linear and nonlinear complementarity problems, Unicomp enables principled transitions and real-time optimization, even with non-convex contact scenarios and capturing effects like torsional friction through an ellipsoidal limit surface [latex]\mathcal{N}=4[/latex]. Could this unified approach unlock more stable and adaptable robotic behaviors for complex manipulation tasks?

Modeling Contact: Bridging the Gap Between Simulation and Reality

The reliable operation of robots in real-world scenarios fundamentally depends on their ability to interact with the environment through physical contact. However, accurately modeling these interactions using traditional continuous dynamics – the mathematical description of motion over time – presents significant challenges. These methods often demand immense computational resources, particularly when dealing with complex geometries or rapid movements, rendering real-time control impractical. Furthermore, continuous simulations are prone to numerical instability, meaning small errors can accumulate and lead to unrealistic or even catastrophic outcomes, especially during impacts or when friction is involved. Consequently, achieving robust and efficient contact simulation remains a core hurdle in robotics, motivating the exploration of alternative approaches that can overcome these limitations.

The accurate simulation of physical interactions, particularly impacts and friction, presents a significant challenge to conventional robotics control systems. Existing methods, often rooted in continuous dynamics, demand extensive computational resources to resolve the complex forces generated during contact, creating bottlenecks for real-time applications. Furthermore, these approaches are prone to numerical instability when dealing with the abrupt changes in velocity and force inherent in impacts, leading to inaccurate simulations and potentially jeopardizing control precision. This difficulty in modeling contact efficiently and reliably directly limits a robot’s ability to plan and execute complex manipulations, navigate dynamic environments, and interact safely with unpredictable objects – ultimately hindering the development of truly adaptable and intelligent robotic systems.

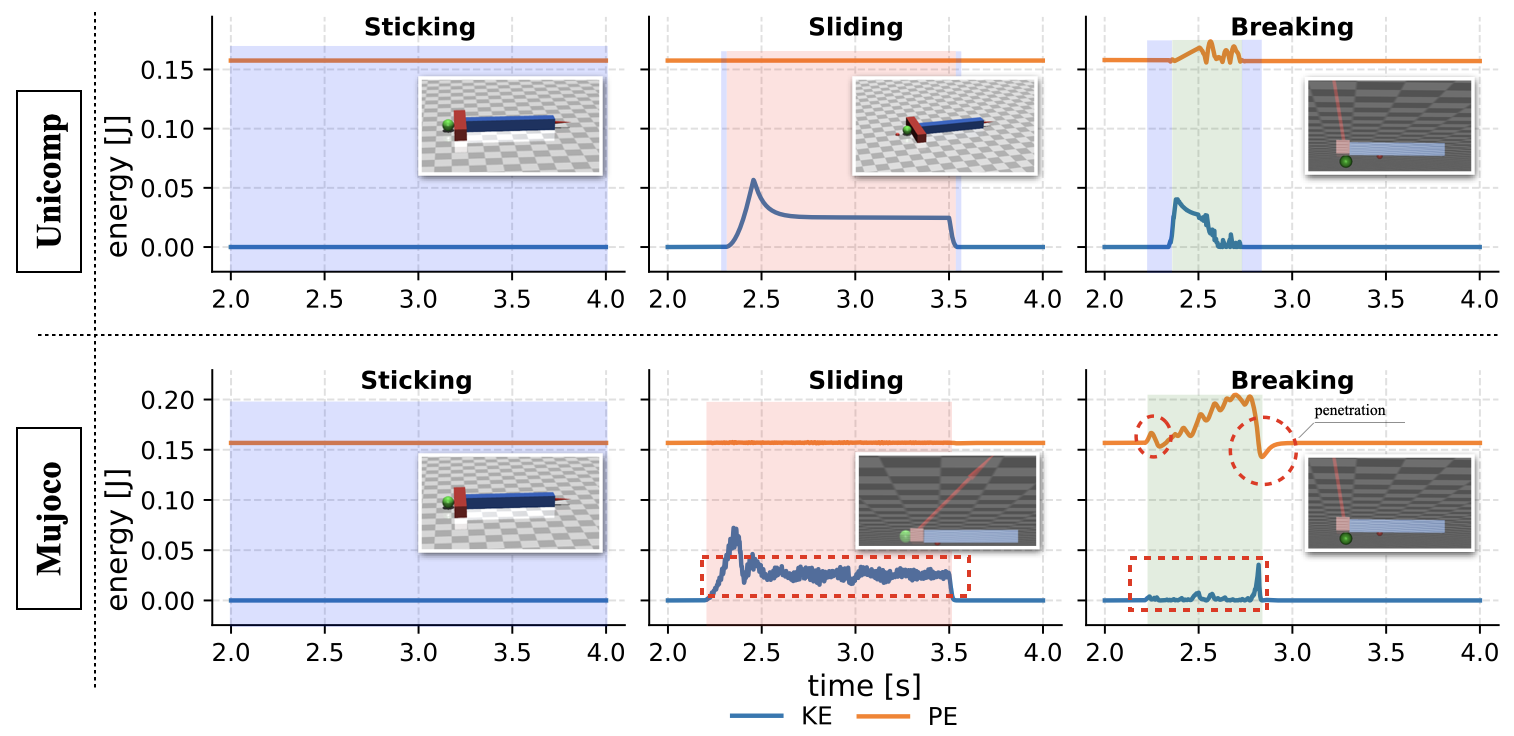

Discrete dynamics presents a compelling alternative to traditional continuous methods for simulating physical contact, offering improvements in both robustness and computational efficiency. By representing time as a series of distinct steps, this approach avoids the numerical instabilities often encountered when solving differential equations that govern continuous systems, particularly during high-velocity impacts or frictional interactions. This discretization allows researchers to formulate contact mechanics as a set of algebraic equations, solvable with efficient numerical techniques, and enables real-time control and planning for robotic systems. Furthermore, discrete-time simulations inherently handle collisions as instantaneous events, simplifying the modeling of complex contact scenarios and reducing the computational burden associated with resolving interpenetrations – a crucial advancement for applications demanding rapid and reliable responses in dynamic environments.

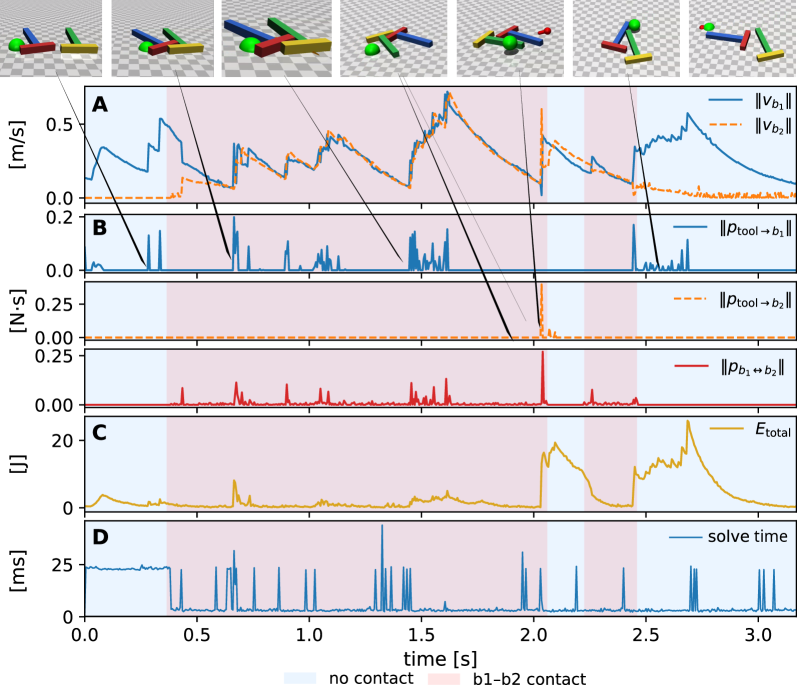

Unicomp: A Framework Rooted in Physical Complementarity

Unicomp utilizes a complementarity-based formulation to model both free-space motion and frictional contact interactions within a dynamic simulation. This approach casts the contact problem as a set of inequalities representing non-penetration and friction constraints. These inequalities, combined with equations of motion, are solved using a specialized solver that efficiently determines the active constraints at each time step. The complementarity formulation allows for the natural handling of impacts and transitions between sticking and sliding friction, accurately representing complex contact scenarios without requiring explicit penetration resolution or ad-hoc constraint enforcement. This results in a stable and robust simulation capable of handling a variety of physical interactions.

Unicomp utilizes Impulse-Based Dynamics to propagate the simulation state, offering computational efficiency when dealing with impacts and collisions. This approach calculates changes in linear and angular velocity directly from impulse forces, bypassing the need for explicit constraint solving at each time step. By formulating motion updates as discrete impulses [latex] \Delta v = J^T \Delta \lambda [/latex], where [latex] J [/latex] is the Jacobian matrix and λ represents the impulse magnitude, the framework minimizes numerical drift and allows for stable simulations even with high-velocity impacts. This method is particularly advantageous for real-time applications as it reduces computational cost compared to traditional time-integration schemes, enabling the handling of numerous contact events at a frequency of 1000 Hz.

Unicomp’s contact handling utilizes a dedicated Contact Detection module to identify collisions between simulated bodies in each time step. Following collision detection, appropriate contact forces – calculated based on material properties and penetration depth – are applied to the involved bodies. This process, optimized for computational efficiency, enables Unicomp to maintain real-time performance, consistently achieving a simulation frequency of 1000 Hz. This high frequency is critical for accurately capturing dynamic interactions and ensuring stability in simulations involving rapid movements and numerous contacts.

Defining Frictional Limits: A Principle of Maximum Power Dissipation

The Ellipsoidal Limit-Surface Model for frictional contact is derived from the Maximum Power Dissipation Principle, which posits that, at the point of impending motion, friction forces will dissipate the maximum possible power consistent with the applied loads. This principle mathematically translates into an ellipsoidal representation of the friction cone, allowing for a non-linear relationship between normal force and tangential (frictional) force/moment. The resulting ellipsoid’s axes are scaled by the normal force, [latex]F_n[/latex], and a material-dependent friction coefficient, μ, effectively capturing the limits of static and dynamic friction. This ellipsoidal formulation accurately represents the complex interplay between force and moment at the contact surface, accounting for scenarios where the friction force and moment are simultaneously active and constrained by the adhesion limit.

The Ellipsoidal Limit-Surface Model, when integrated with a Linear Complementarity Problem (LCP), enforces physically realistic contact forces by mathematically defining allowable force ranges and preventing their violation. The LCP formulation specifically addresses the non-penetration condition and ensures that contact forces are non-negative under compression, while allowing for zero force when surfaces separate. This constraint is crucial for simulating stable contact as it avoids unrealistic force values or behaviors that would occur if forces were allowed to exceed frictional limits or act in tension across a contact surface. Solving the LCP within the simulation loop determines the magnitude of the contact forces, guaranteeing they remain within the bounds defined by the material properties and geometric constraints of the contact.

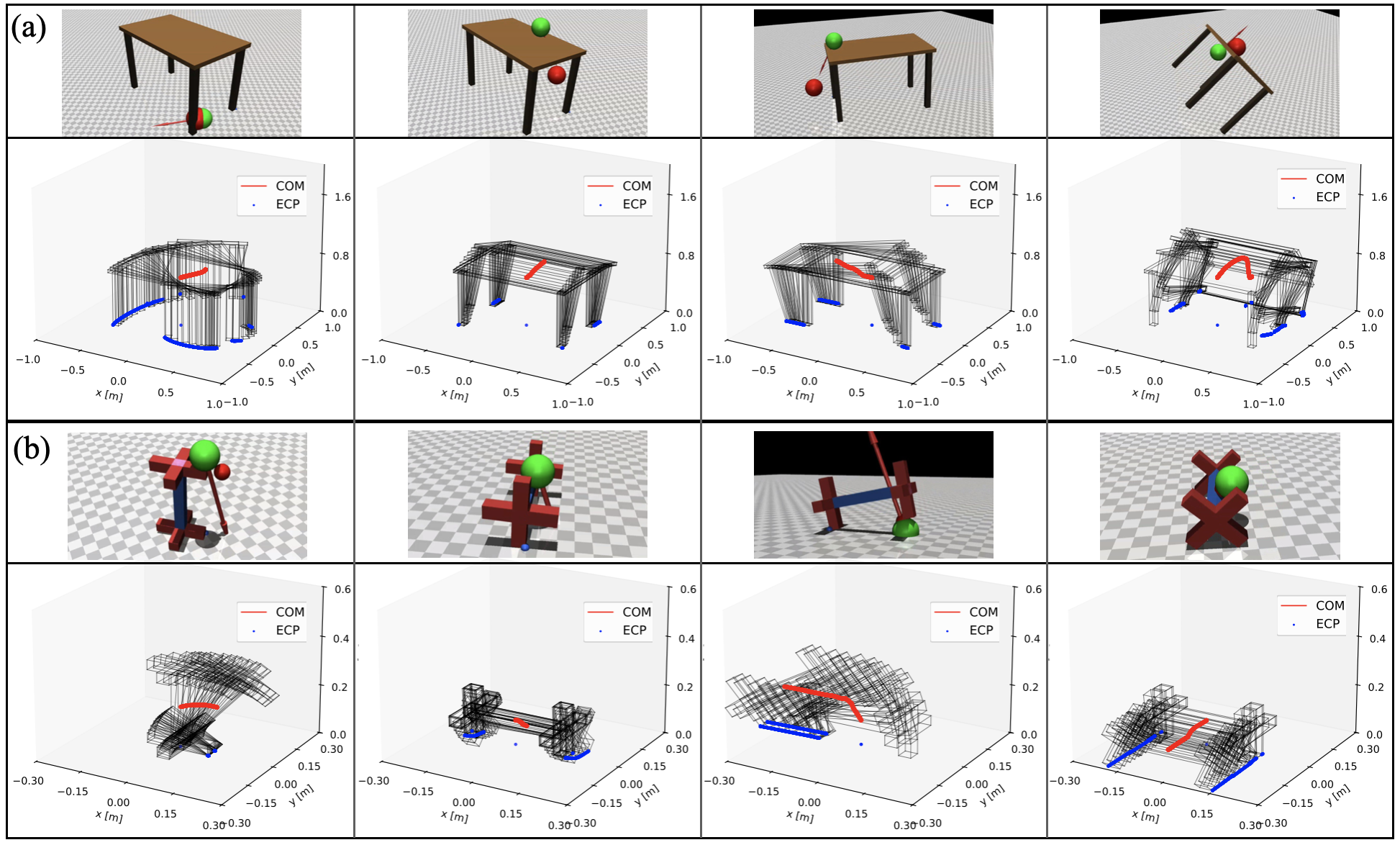

Unicomp facilitates stable contact transitions in multi-body dynamics simulations by avoiding reliance on pre-defined contact modes or fixed-contact assumptions. This is achieved through a formulation that inherently manages mode switching as a consequence of force and displacement calculations, eliminating the need for explicit mode enumeration or complex switching logic. Consequently, the system accurately propagates impulses and resulting motion across interconnected bodies, allowing for realistic simulation of complex interactions and maintaining stability even with significant dynamic changes and contact sequences within the scene.

![During tool-driven pushing, complementarity signatures-[latex]s \approx 1[/latex] for sliding and [latex]s < 1[/latex] for sticking-persist despite non-smooth excitation from tool contact, indicating consistent contact mechanics at the block-ground contact point ([latex]\Lambda\_{n}, \boldsymbol{\Lambda}, s, \rho\_{t}, \rho\_{r}[/latex]).](https://arxiv.org/html/2602.04522v1/x1.png)

Extending Capabilities: Whole-Body Control and Trajectory Optimization

Robotic systems operating in complex environments require robust strategies for preventing collisions, and Unicomp addresses this challenge with a computationally efficient approach to contact event management. Rather than relying on exhaustive, real-time environmental mapping, Unicomp prioritizes rapid detection of impending contact, allowing for immediate adjustments to the robot’s trajectory. This is achieved through a unique formulation that streamlines the calculation of contact forces and leverages simplified dynamics models, drastically reducing the computational burden compared to traditional methods. The system doesn’t merely identify potential collisions; it also provides a framework for quickly generating reactive control actions, ensuring the robot can dynamically respond to unforeseen obstacles and maintain stable, collision-free operation across its entire body. This speed and efficiency are critical for applications demanding real-time responsiveness, such as collaborative robotics and dynamic locomotion.

Task-Space Impedance Control forms the core of a robot’s ability to dynamically adapt to external forces and maintain stable interactions with its surroundings. Rather than rigidly following a pre-planned trajectory, this technique allows the robot to modulate its stiffness and damping characteristics in the task space – the space defined by the robot’s desired end-effector position and orientation. Essentially, the robot behaves as a virtual spring-damper system, resisting unexpected forces while simultaneously conforming to gentle contacts. This is achieved by mapping joint torques to desired end-effector behavior, enabling nuanced responses to disturbances and facilitating the execution of complex manipulations, even in uncertain or dynamic environments. The result is a robot that doesn’t simply react to its environment, but actively regulates its interaction, promoting both safety and precision.

The capacity for robots to navigate complex environments hinges on their ability to plan and execute movements that avoid obstacles while remaining fluid and efficient. By integrating Unicomp with surface sampling techniques and trajectory optimization algorithms, researchers have achieved significant advancements in this area. Surface sampling allows the robot to build a detailed representation of its surroundings, identifying potential contact points and feasible pathways. This information is then fed into trajectory optimization, which refines the robot’s planned path to minimize travel time, energy consumption, and the risk of collisions. The result is a system capable of generating remarkably smooth and safe motions, even in dynamic and cluttered spaces, effectively bridging the gap between theoretical planning and real-world robotic execution.

The presented work, Unicomp, embodies a holistic approach to rigid-body manipulation, recognizing that simplification invariably introduces trade-offs. This mirrors the observation of Blaise Pascal: “The eloquence of angels is not syllogistic.” While the framework employs mathematical rigor to model contact dynamics and collision avoidance, its true strength lies in its unified treatment of complex interactions, avoiding the pitfalls of overly prescriptive methods. Just as Pascal suggests that pure logic fails to capture the full scope of understanding, Unicomp acknowledges that rigid-body systems are rarely defined by simple, pre-defined contact modes; instead, a comprehensive model of complementarity is required to truly represent the system’s behavior.

What Lies Ahead?

The elegance of Unicomp resides in its attempt to sidestep the brittle categorization inherent in most contact models. Yet, systems break along invisible boundaries-if one cannot accurately represent the potential for contact, even with a unified framework, the inevitable divergence from reality will manifest as instability. The current formulation, while demonstrating real-time capabilities, still implicitly relies on a reasonably accurate initial guess for the contact manifold. Future work must address the robustness of the system when faced with significant uncertainty in this initial state, or, more radically, develop methods to learn the contact manifold directly from sensor data.

A crucial limitation lies in the computational cost of solving the complementarity problem, particularly as the number of contact points increases. While the current implementation achieves real-time performance, scaling to highly complex manipulation tasks-consider the dexterous assembly of intricate objects-will demand novel algorithmic approaches. Exploring the interplay between complementarity programming and learning-based techniques, such as neural networks trained to predict contact forces, offers a potential avenue for acceleration.

Ultimately, the true test of this approach-and indeed, of any framework for robotic manipulation-is its capacity to handle the unexpected. A system that anticipates not just the how of contact, but the where and when of its failures, is a system approaching genuine intelligence. The challenge is not merely to model contact, but to model the absence of contact-the subtle shifts in geometry and force that herald a loss of stability, and to respond before the inevitable cascade begins.

Original article: https://arxiv.org/pdf/2602.04522.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Clash of Clans Unleash the Duke Community Event for March 2026: Details, How to Progress, Rewards and more

- Brawl Stars February 2026 Brawl Talk: 100th Brawler, New Game Modes, Buffies, Trophy System, Skins, and more

- Gold Rate Forecast

- MLBB x KOF Encore 2026: List of bingo patterns

- eFootball 2026 Show Time Worldwide Selection Contract: Best player to choose and Tier List

- Free Fire Beat Carnival event goes live with DJ Alok collab, rewards, themed battlefield changes, and more

- Brent Oil Forecast

- Magic Chess: Go Go Season 5 introduces new GOGO MOBA and Go Go Plaza modes, a cooking mini-game, synergies, and more

- eFootball 2026 Starter Set Gabriel Batistuta pack review

- Overwatch Domina counters

2026-02-05 19:12