Author: Denis Avetisyan

Researchers have created the first macro-scale rotary motor built from folded structures and powered by electrostatic forces, opening up new possibilities for deployable robotics.

This work demonstrates a functional, macro-scale electrostatic origami motor utilizing a Kresling cylinder design for collapsible actuation.

While foldable robots offer advantages in portability and adaptability, existing designs rely on bulky actuators or limited motion types. This paper details the development of a novel ‘Macro-Scale Electrostatic Origami Motor’-a collapsible rotary actuator leveraging electrostatic principles and a Kresling cylinder structure. The prototype achieved a 2.5:1 expansion ratio, reaching 1440 rpm at -29 kV with a torque density of 0.04 Nm/kg, demonstrating the feasibility of a macro-scale, foldable rotary actuator. Could this approach pave the way for a new generation of deployable robots and flexible electromechanical systems?

Beyond Conventional Actuation: Embracing Electrostatic Potential

The prevalence of electromagnetic motors in modern technology belies inherent constraints that become increasingly problematic at smaller scales. These motors rely on magnetic fields generated by current-carrying coils, a process which demands substantial material volume and energy input, hindering miniaturization efforts. As devices shrink, maintaining comparable torque output becomes exponentially more difficult, requiring increasingly complex designs and powerful magnetic materials. Furthermore, the very nature of electromagnetic induction leads to energy losses through eddy currents and hysteresis, reducing overall efficiency – a critical limitation for battery-powered applications and sustainable engineering. Consequently, despite their widespread use, conventional motors are reaching the limits of their scalability and performance, prompting exploration into alternative actuation methods like electrostatic systems.

Electrostatic motors present a compelling alternative to conventional electromagnetic designs, particularly in applications demanding small size and minimal power consumption. These devices leverage the forces generated by electric fields, enabling potentially dramatic reductions in both weight and energy use – crucial for micro-robotic systems and precision instruments. However, realizing practical electrostatic motors is not without significant hurdles. The inherently weak nature of electrostatic forces necessitates extremely small gaps between moving parts, creating manufacturing challenges and increasing susceptibility to contamination. Furthermore, achieving sustained rotational motion requires clever designs to overcome the limited torque generated and maintain stable operation, often involving complex electrode geometries and sophisticated control algorithms to prevent unwanted oscillations or static cling. Ongoing research focuses on innovative materials, advanced fabrication techniques, and novel control strategies to enhance both the power output and reliability of these promising micro-actuators.

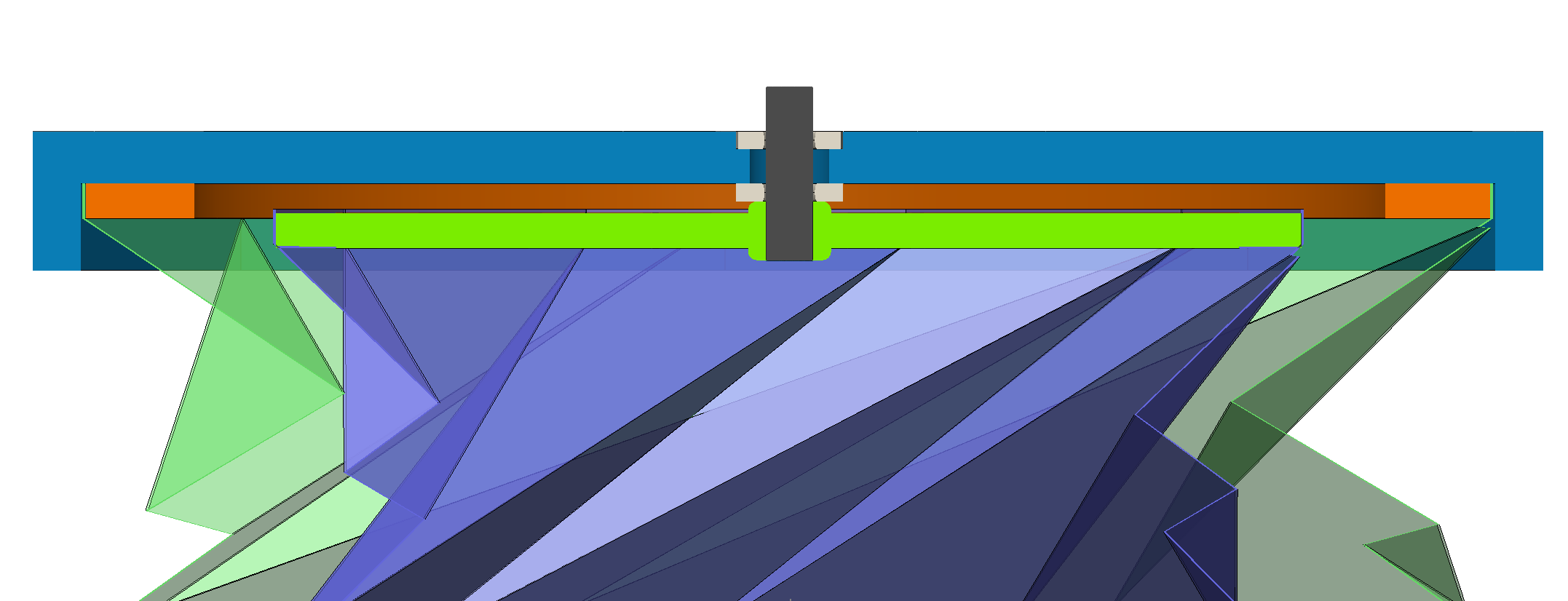

![This electrostatic origami motor expands from [latex]26.5\,\text{mm}[/latex] to [latex]66.0\,\text{mm}[/latex] and maintains a stable, deployed position without external force after unfurling from its stowed configuration.](https://arxiv.org/html/2601.21976v1/media/unfurled3.jpg)

Origami’s Geometry: A Foundation for Minimalist Motion

The Kresling cylinder, employed as the core structural element of the motor, is a cylindrical structure formed by creasing a flat sheet into a repeating pattern of mountain and valley folds. This origami-based design exhibits high bending resistance due to the geometric interlocking of its facets, distributing stress across the entire structure rather than concentrating it at single points. This inherent rigidity, achieved with a lightweight construction, allows the motor to withstand external forces and maintain its shape during operation. The pattern’s ability to expand and contract axially while resisting radial deformation is critical to the motor’s function, providing both support and a degree of compliance.

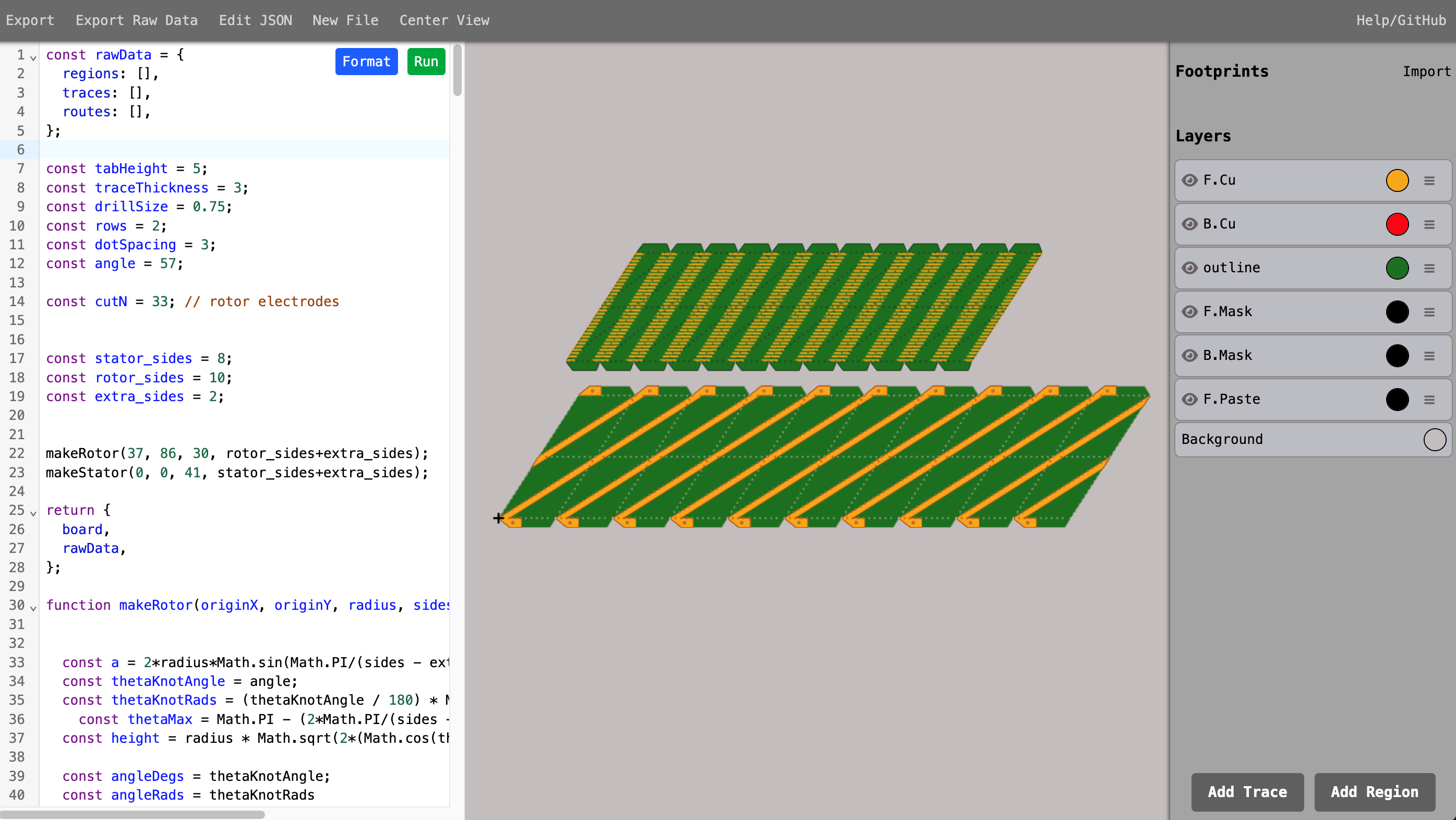

Flexible Printed Circuit Boards (FPBs) are utilized in the motor’s construction to serve as both the structural components of the rotor and stator, and to integrate the necessary electrical circuitry. FPBs enable the creation of complex, three-dimensional geometries that are not readily achievable with traditional rigid printed circuit boards. This is achieved through the use of thin, flexible substrates – typically polyimide – onto which conductive traces and components are deposited. The inherent flexibility of FPBs allows for repeated bending and flexing without compromising electrical performance, and facilitates the tight integration of wiring directly into the structural elements of the rotor and stator, reducing assembly complexity and minimizing parasitic inductance.

Rigid components of the motor are manufactured using 3D printing techniques, enabling the creation of complex geometries necessary for housing and supporting the flexible components. To minimize rotational friction and ensure long-term operational stability, the design incorporates Sapphire Jewel Bearings at key contact points. Sapphire was selected due to its high hardness, wear resistance, and low coefficient of friction, significantly reducing energy loss and extending the lifespan of the rotating assembly compared to traditional bearing materials. These bearings provide a consistently smooth rotational axis, critical for maintaining the motor’s precision and efficiency.

Modeling the Invisible: Understanding Corona Discharge

The operation of this motor relies on corona discharge, a phenomenon occurring in the air gap between electrodes due to a strong electric field exceeding the dielectric strength of air. Consequently, the modeling effort centers on accurately representing this ionized region, as it directly influences the motor’s performance characteristics. The air gap is not a simple vacuum; it contains free electrons and ions created by the discharge, altering its electrical conductivity and creating a distributed capacitance. Precise characterization of this ionized air gap requires consideration of gas composition, pressure, electrode geometry, and applied voltage to effectively simulate the electric field distribution and current flow responsible for torque generation.

Effective conductivity, denoted as [latex]\sigma_{eff}[/latex], is employed to represent the electrically conductive properties of the ionized air gap within the motor, simplifying the complex physics of corona discharge for computational modeling. This parameter aggregates the contributions of both neutral and ionized air molecules to electrical conduction, allowing for the treatment of the air gap as a homogeneous medium with a spatially varying conductivity. By incorporating [latex]\sigma_{eff}[/latex] into the motor’s electromagnetic model, simulations can accurately predict the electric field distribution and current flow, directly influencing the calculation of electrostatic forces and ultimately, the generated torque. The value of [latex]\sigma_{eff}[/latex] is dependent on the applied voltage, air pressure, and the concentration of ionizing species, requiring iterative solution techniques to determine its spatial distribution within the air gap for varying operational conditions.

The motor’s design leverages foundational principles of Electrostatic Induction Machines, drawing heavily from the theoretical and experimental work of Heinrich von Quincke and Robert Melcher. Von Quincke’s investigations into electrostatic motors, particularly his use of rotating conductors and induced charges, established key operational concepts. Melcher’s subsequent research extended these principles through detailed analyses of electrostatic fields and forces within conductive media, including models for charge distribution and induced currents. The current design incorporates these established models to predict performance characteristics, optimize electrode geometry, and account for the effects of dielectric materials on electrostatic field strength and charge transfer, ensuring a robust and predictable operational framework.

![The measured steady-state torque of the motor closely matches the model developed in Section III, validated with parameters [latex]R = L = 30 \text{ mm}[/latex], [latex]G = 3.5 \text{ mm}[/latex], [latex]\epsilon_g = \epsilon_0[/latex], [latex]V_{onset} = -{10}.5 \text{ kV}[/latex], and [latex]\alpha = 0.15 \text{ rad}[/latex].](https://arxiv.org/html/2601.21976v1/media/graphs/torque_vs_voltage.png)

Performance Validated: Quantifying Dynamic Capabilities

Precise characterization of the motor’s dynamic performance relied on detailed analysis of its rotational behavior, captured through high-speed camera footage. This technique allowed researchers to move beyond static measurements and quantify both the motor’s rotational speed – reaching a maximum of 1440 rpm – and its acceleration capabilities with a high degree of accuracy. By recording the motor’s motion at a sufficiently high frame rate, subtle changes in velocity could be detected and analyzed, providing valuable insights into its operational characteristics and enabling the precise calculation of key performance metrics. The resulting data forms the foundation for validating the motor’s design and assessing its suitability for targeted applications where both speed and responsiveness are critical.

Precise quantification of the motor’s performance relied heavily on Tracker, a dedicated video analysis software. This tool allowed researchers to meticulously process high-speed camera footage, converting visual data into quantifiable metrics of dynamic behavior. By tracking the motor’s rotation across numerous frames, Tracker enabled the accurate calculation of angular velocity, acceleration, and subsequent torque values. The software’s capabilities extended beyond simple tracking; it facilitated detailed analysis of the motor’s movement patterns, revealing subtle variations and ensuring the reliability of the collected data, ultimately contributing to a comprehensive understanding of its operational characteristics and enabling precise determination of key performance indicators like volumetric torque density.

The motor’s performance characteristics demonstrate a capability of reaching 1440 revolutions per minute when driven by a -29 kilovolt potential. Under these conditions, the motor generates a peak torque of 0.2 millinewton-meters; however, when subjected to a typical operational load, the output torque settles at a consistent 0.15 mN m. This distinction between peak and loaded torque highlights the motor’s ability to maintain substantial rotational force even under practical working conditions, suggesting efficient energy conversion and stable operational behavior within the designed parameters.

The motor’s design prioritizes compactness and power, yielding a notable volumetric torque density – a measure of torque generated per unit volume. In its operational, deployed state, the motor achieves a volumetric torque density of 0.54 N m m⁻³. However, a key innovation lies in its ability to transition to a stowed configuration, dramatically increasing this metric to an impressive 1.35 N m m⁻³. This substantial increase demonstrates the design’s efficiency in minimizing size without sacrificing performance, offering a significant advantage in applications where space is limited and high torque output is crucial, and highlighting its potential for integration into miniaturized robotic systems and other compact devices.

![High-speed camera data reveals that after being powered on and off, the motor spins down while exhibiting speed oscillations in the [latex]-{29} ext{kV}[/latex] trial, likely caused by axial rotor movement towards the stator end cap.](https://arxiv.org/html/2601.21976v1/media/graphs/speed_time_series.png)

Looking Forward: Expanding the Potential of Minimalist Actuation

The current design isn’t a fixed endpoint, but rather a springboard for further innovation through the exploration of different origami-inspired geometries. Researchers are actively investigating alternative folding patterns, notably the Yoshimura Pattern and the Tachi-Miura Pattern, to optimize the motor’s deployment characteristics and overall performance. These patterns offer potentially greater expansion ratios and tailored stiffness profiles, allowing for customization based on specific application requirements. By leveraging the inherent adaptability of origami principles, future iterations could yield motors with enhanced functionality, increased robustness, and even entirely new methods of actuation – all while maintaining the benefits of compact storage and rapid deployment.

The motor’s construction leverages JSON-PCB, a methodology that dramatically streamlines the fabrication process and unlocks unprecedented design flexibility. This approach allows for the creation of custom circuit board layouts directly from JSON data, effectively translating digital designs into physical prototypes with exceptional speed. Consequently, iterative development cycles are significantly shortened, enabling researchers and engineers to rapidly test and refine motor configurations tailored to specific application requirements. The inherent adaptability of JSON-PCB not only accelerates prototyping but also facilitates the production of highly customized motors with varying sizes, shapes, and performance characteristics – a crucial advantage for specialized micro-robotic systems and other miniaturized devices where off-the-shelf components are often insufficient.

The developed motor distinguishes itself through exceptional kinematic properties, boasting a remarkably low rotor moment of inertia of [latex]4.24 \times 10^{-6} \text{ kg m}^2[/latex]. This characteristic, coupled with a 2.5:1 expansion ratio achieved during deployment, positions the device as a compelling solution for applications demanding precise and efficient movement at miniature scales. Such specifications are particularly advantageous in the burgeoning field of micro-robotics, enabling the creation of agile and responsive systems. Beyond robotics, the compact design and dynamic capabilities offer potential for innovation in areas like minimally invasive medical devices, deployable space structures, and advanced micro-electromechanical systems where size and performance are paramount.

The presented work prioritizes functional simplicity. The macro-scale electrostatic origami motor achieves rotary motion through a deliberately sparse configuration, mirroring a focus on essential mechanics. This aligns with Vinton Cerf’s observation: “The Internet treats everyone the same.” While ostensibly about network protocols, the sentiment extends to engineering design; the most robust systems are those built on universal principles, readily adaptable and broadly applicable. The Kresling cylinder’s inherent ability to transition between flattened and expanded states exemplifies this principle, demonstrating a foundational geometry capable of driving complex actuation with minimal components. The elegance resides not in intricacy, but in efficient execution of fundamental laws.

Further Refinements

The demonstration of macro-scale electrostatic actuation through folded structures, while a necessary first step, exposes the inherent challenges of scaling this approach. Current reliance on corona discharge for charge generation introduces limitations in operational lifespan and repeatability. The pursuit of more stable, efficient charge delivery mechanisms – perhaps exploring triboelectric effects or integrated flexible charging systems – represents a critical avenue for future work. Simplification, naturally, is paramount.

Beyond charge generation, the material science underpinning these foldable actuators demands reconsideration. The present design, while functional, is constrained by the mechanical properties of available flexible substrates. A shift towards self-healing polymers or intrinsically stretchable conductors could unlock more complex and robust origami designs, diminishing the need for over-engineering to compensate for material fragility. The elegance of a system is inversely proportional to its reliance on brute force.

Ultimately, the true measure of this work will not be in replicating the existing rotary motion, but in applying these principles to genuinely novel robotic architectures. The Kresling cylinder, while a useful proof-of-concept, is a solution searching for a problem. The field should focus on identifying tasks where the unique advantages of foldable, electrostatically actuated structures – deployability, adaptability, and intrinsic compliance – offer a distinct advantage over conventional actuation methods. Less is demonstrably more.

Original article: https://arxiv.org/pdf/2601.21976.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- MLBB x KOF Encore 2026: List of bingo patterns

- eFootball 2026 Jürgen Klopp Manager Guide: Best formations, instructions, and tactics

- Overwatch Domina counters

- Brawl Stars Brawlentines Community Event: Brawler Dates, Community goals, Voting, Rewards, and more

- eFootball 2026 Starter Set Gabriel Batistuta pack review

- Honkai: Star Rail Version 4.0 Phase One Character Banners: Who should you pull

- Gold Rate Forecast

- 1xBet declared bankrupt in Dutch court

- Lana Del Rey and swamp-guide husband Jeremy Dufrene are mobbed by fans as they leave their New York hotel after Fashion Week appearance

- Clash of Clans March 2026 update is bringing a new Hero, Village Helper, major changes to Gold Pass, and more

2026-01-30 18:01