Author: Denis Avetisyan

This review explores the rapidly evolving field of flexible robotics, focusing on how multiple continuum robot arms are being combined to tackle complex tasks.

![The evolution of collaborative robotics demonstrates a clear trajectory toward increasingly specialized surgical and repair applications, as evidenced by designs ranging from the dual-arm dexterity of the YuMi [13] to dedicated research platforms developed by institutions like the Hong Kong Polytechnic University [14], Waseda University [15], the University of Nottingham [16], and Shanghai Jiao Tong University [17], alongside the established precision of the Da Vinci surgical robot [12].](https://arxiv.org/html/2601.10721v1/x1.png)

A comprehensive survey of design, modeling, control, and applications for multi-arm collaborative continuum robot systems.

While traditional robotics excels in structured environments, complex tasks often demand greater adaptability and dexterity. This paper, ‘Collaborative Continuum Robots: A Survey’, comprehensively reviews the emerging field of multi-arm systems utilizing continuum robots to overcome these limitations. By classifying collaboration modes and detailing advancements in design, modeling, and control, the survey reveals a path toward significantly enhanced task performance and workspace flexibility. Will intelligent design, data-driven modeling, and reinforcement learning unlock the full potential of these collaborative, deformable systems in real-world applications?

The Inevitable Limits of Precision

Conventional surgical robotics, celebrated for their unwavering precision, frequently encounter limitations when confronted with the intricate geometries within the human body. These systems, often employing rigid linkages and bulky actuators, struggle to replicate the nuanced movements of a surgeon’s hand when navigating the convoluted pathways of minimally invasive procedures. While capable of executing programmed tasks with remarkable accuracy, their restricted range of motion and inability to conform to irregular anatomical features can hinder access to target tissues and increase operative complexity. This inflexibility necessitates careful pre-operative planning and potentially limits the surgeon’s ability to adapt to unforeseen circumstances encountered during the procedure, highlighting a critical need for more adaptable robotic platforms.

Current minimally invasive surgical techniques, while offering benefits like reduced trauma and faster recovery, are significantly hampered by the limited range of motion available to robotic instruments. Traditional designs often rely on a fixed number of joints, restricting maneuverability within the body’s narrow passages and around delicate tissues. This lack of degrees of freedom – the ability to move in multiple directions – forces surgeons to make compromises, potentially increasing procedure time and the risk of complications. Existing methods attempt to address this through complex linkages or remote center motion, but these solutions often introduce further mechanical complexity and can still fall short of replicating the natural dexterity of a human hand within a confined surgical field. Consequently, a substantial need exists for robotic systems that can truly navigate and operate effectively within the challenging geometry of minimally invasive access points.

The limitations of current surgical robotics within the confines of minimally invasive procedures demand a fundamental rethinking of robotic design. Traditional rigid systems struggle with the complex geometries and restricted access characteristic of these operations, prompting a move towards highly adaptable robots. These next-generation devices prioritize maneuverability, employing flexible materials, multi-segment architectures, and novel actuation methods to navigate tortuous pathways. The goal is not simply to replicate human dexterity, but to surpass it with robotic systems capable of reaching, orienting, and manipulating tissues in spaces inaccessible to conventional instruments – ultimately promising less invasive procedures, reduced patient trauma, and improved surgical outcomes.

Bio-Inspired Flexibility: The Promise of Continuum Robotics

Continuum robots (CRs) differentiate themselves from traditional rigid-bodied robots through the implementation of highly flexible structures, drawing inspiration from biological systems such as elephant trunks and octopus arms. This design approach allows CRs to navigate complex and constrained environments with greater dexterity and reach than conventional robots. The flexibility is typically achieved using materials like polymers, allowing for infinite degrees of freedom in motion, and enabling the robot to bend, twist, and extend into tight spaces. This enhanced maneuverability is particularly beneficial in applications like minimally invasive surgery, inspection of hard-to-reach areas, and search and rescue operations, where adaptability is crucial.

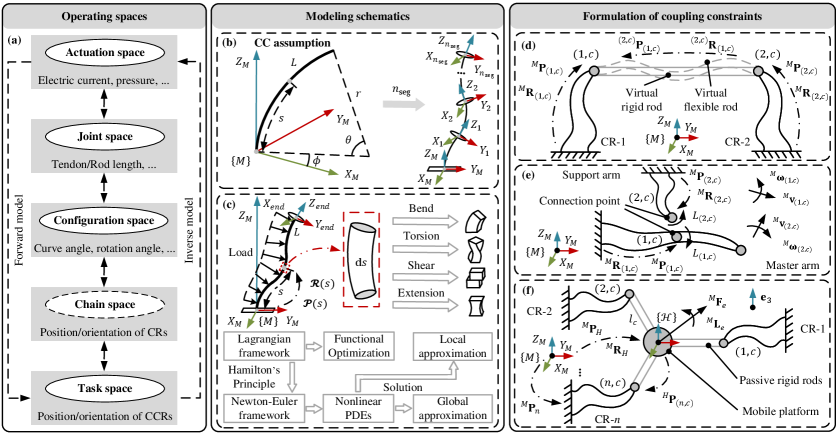

Modeling continuum robots (CRs) necessitates the use of advanced techniques like Cosserat Rod Theory due to their infinite degrees of freedom and highly deformable nature. Unlike traditional rigid-body kinematics, Cosserat Rod Theory describes the robot’s pose not just through position and orientation, but also through curvature and torsion at each point along its flexible spine. This approach accounts for bending and twisting deformations, which are fundamental to CR movement. The theory mathematically defines the relationship between applied forces/torques and resulting deformation, utilizing a differential relationship between the robot’s shape and its internal stresses. It incorporates parameters like flexural rigidity EI and torsional rigidity GJ to quantify the resistance to bending and twisting, respectively, enabling accurate prediction of the robot’s configuration under load. Consequently, Cosserat Rod Theory provides a framework for forward kinematics, inverse kinematics, and dynamic analysis of CRs, crucial for effective control and path planning.

Due to the infinite degrees of freedom inherent in continuum robot (CR) structures, precise control and path planning are computationally expensive. To address this, simplified modeling approaches are frequently used. The Constant Curvature Assumption posits that the robot’s deformation is governed by a single curvature value, reducing the configuration space and enabling more tractable control algorithms. Alternatively, the Pseudo-Rigid-Body Model discretizes the CR into a series of rigid links connected by spherical joints, approximating the continuous deformation with a finite number of parameters. These simplifications allow for the application of established robotics control techniques – typically designed for rigid-bodied robots – to CRs, although at the cost of potentially reduced accuracy in representing complex deformations and dynamic behavior.

Accurate state estimation is crucial for effective control of continuum robots due to their infinite degrees of freedom and complex deformation. Techniques such as the Extended Kalman Filter (EKF) are frequently implemented to estimate the robot’s pose – position and orientation – and internal states, such as curvature or strain, from noisy sensor data. The EKF operates by propagating a Gaussian probability distribution representing the robot’s state through a dynamic model and then updating that distribution based on measurements obtained from sensors like encoders, IMUs, or vision systems. This recursive process minimizes the estimation error and provides a best estimate of the robot’s configuration, enabling precise and reliable control despite uncertainties in both the robot’s dynamics and sensor readings. \hat{x}_{k|k} = \hat{x}_{k|k-1} + K_k(z_k - h(\hat{x}_{k|k-1})) represents the update step, where \hat{x} is the state estimate, z is the measurement, h is the measurement model, and K is the Kalman gain.

Synergistic Systems: The Evolution of Multi-Arm Collaboration

Multi-Arm Collaborative Continuum Robot (MACCR) systems integrate multiple continuum robots (CRs) to achieve capabilities exceeding those of single-arm systems. Individual CRs possess inherent limitations in workspace, load capacity, and dexterity; MACCR configurations address these by combining the strengths of each arm. This approach enables expanded reach, increased payload manipulation, and improved dexterity in complex environments. Combining multiple CRs also offers redundancy, enhancing system robustness and fault tolerance. The specific benefits derived from a MACCR system are directly related to the number of CRs integrated and the chosen collaborative configuration, allowing for tailored robotic solutions for specialized tasks.

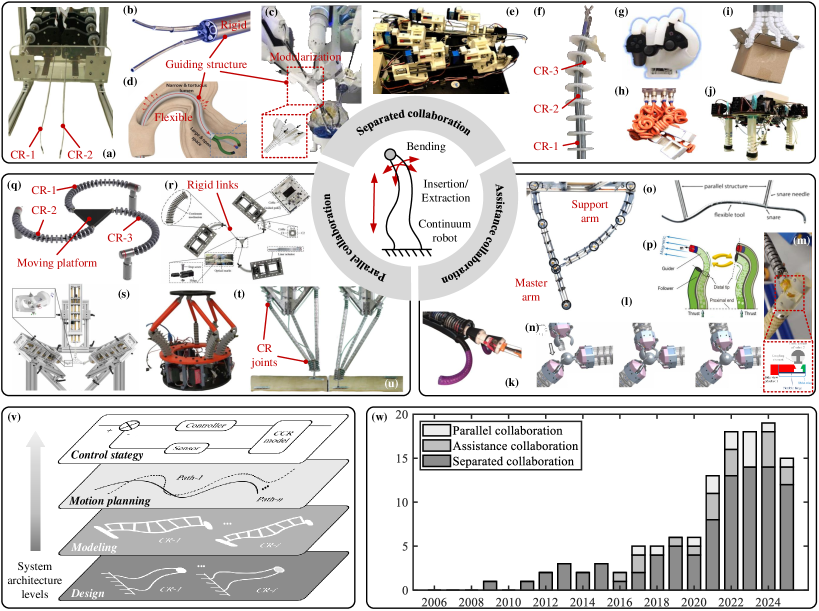

Multi-arm collaborative robotic systems employ distinct collaboration modes to achieve varying degrees of operational synergy. Separated Collaboration involves each robotic arm performing independent tasks within a shared workspace, requiring minimal inter-arm coordination. Assistance Collaboration designates one arm as the primary manipulator while others provide support – for example, holding a part or counteracting external forces – leading to improved stability and payload capacity. Parallel Collaboration utilizes all arms concurrently to perform a single, complex task, such as manipulating a large object or executing intricate assembly procedures, which demands precise synchronization and trajectory planning to avoid collisions and maximize efficiency.

Effective coordination of multi-arm collaborative robotic systems necessitates advanced control strategies such as Hierarchical Control and Switching Control. Hierarchical Control decomposes the complex task into sub-tasks, assigning each to individual arms while a higher-level controller manages interactions and prevents collisions. Switching Control dynamically allocates tasks between arms based on real-time performance metrics and environmental changes, optimizing for efficiency and robustness. These strategies address the increased complexity of kinematic and dynamic coupling inherent in multi-arm systems, enabling precise and synchronized movements that would be unattainable with independent single-arm control. Furthermore, these approaches facilitate adaptability to unforeseen circumstances and allow for seamless transitions between different collaboration modes.

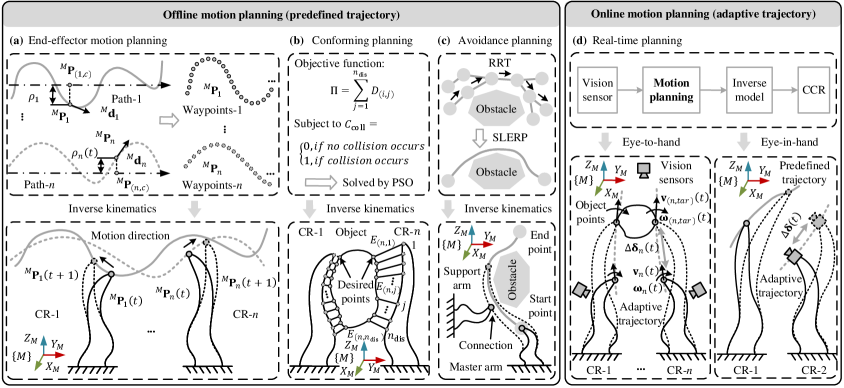

Online Motion Planning facilitates real-time trajectory generation and adaptation in multi-arm robotic systems by continuously calculating and modifying robot paths based on dynamic environments and task requirements. This is frequently achieved through the integration of Reinforcement Learning (RL), where agents learn optimal policies through trial and error, and Offline Motion Planning, which pre-computes feasible trajectories for rapid access. Combining these techniques allows for robust performance; Offline Planning provides initial trajectories and safe fallback options, while RL refines movements and adapts to unforeseen circumstances. The resulting system enables robots to react to changes in real-time, improving efficiency and reliability in complex tasks by dynamically adjusting trajectories rather than relying solely on pre-programmed sequences.

The Convergence of Physics and Machine Learning: Intelligent Control Systems

Physics-Informed Neural Networks (PINNs) are rapidly becoming a cornerstone in advanced control systems, particularly where accurate modeling of complex physical phenomena is crucial. These networks distinguish themselves by seamlessly integrating governing physical equations directly into the machine learning process. Unlike traditional neural networks that rely solely on data, PINNs leverage established physical principles – such as those defining continuous deformations – as a form of regularization. This approach dramatically improves the network’s ability to generalize to unseen scenarios and reduces the need for massive datasets. By satisfying physical constraints during training, PINNs not only predict system behavior more accurately but also exhibit enhanced robustness against noisy data or incomplete observations, leading to more reliable and predictable control outcomes. The result is a powerful synergy where data-driven learning is guided and constrained by fundamental physical laws, fostering a new generation of intelligent control systems.

The predictive power of Physics-Informed Neural Networks (PINNs) receives a significant boost when incorporating the principles of Cosserat Rod Theory, a mathematical framework describing the mechanics of slender bodies. This integration isn’t merely about adding data; it’s about fundamentally shaping the learning process with established physical laws. Cosserat Rod Theory provides constraints on the expected behavior of flexible structures – how they bend, twist, and deform under stress – and these constraints are directly embedded into the neural network’s loss function. Consequently, the network isn’t simply memorizing training data but learning a solution that adheres to realistic physical possibilities. This approach dramatically improves generalization, allowing the PINN to accurately predict behavior even in scenarios not explicitly encountered during training, and also enhances robustness against noisy or incomplete data, leading to more reliable control strategies for complex robotic systems.

The fusion of physics-based modeling and machine learning yields control systems notable for their heightened efficiency and dependability, particularly when navigating challenging and unpredictable conditions. Traditional control methods often struggle with the inherent uncertainties present in real-world applications, requiring extensive recalibration or exhibiting diminished performance. However, by embedding physical constraints directly into the learning process, these networks demonstrate a remarkable ability to extrapolate beyond training data and maintain stable, accurate control even amidst disturbances or incomplete information. This robustness stems from the network’s inherent understanding of the system’s underlying physics, allowing it to anticipate and compensate for variations in a way purely data-driven approaches cannot. Consequently, the resulting control strategies require less computational power and fewer corrective actions, optimizing performance and resource allocation in dynamic environments.

The convergence of physics-based modeling and machine learning promises a revolution in surgical robotics, potentially enabling fully autonomous interventions characterized by remarkable precision and adaptability. By embedding the established principles of mechanics – such as those governing soft tissue deformation and instrument interaction – directly into the learning algorithms, robotic systems can move beyond purely data-driven approaches. This allows for more robust performance in unpredictable surgical environments and reduces the reliance on extensive training datasets. Consequently, autonomous surgical robots, guided by this integrated intelligence, could navigate complex anatomical landscapes, execute intricate maneuvers with sub-millimeter accuracy, and dynamically adjust to unforeseen circumstances – ultimately enhancing patient outcomes and expanding the possibilities of minimally invasive surgery.

The survey of collaborative continuum robots reveals a landscape where predictability yields to emergent behavior. These systems, unlike rigid counterparts, are defined by their adaptability, their ability to reshape themselves within an environment. This echoes a sentiment articulated by Robert Tarjan: “Everything built will one day start fixing itself.” The very nature of continuum robots-their flexible structures and reliance on data-driven modeling-suggests a move away from pre-defined control and toward self-correcting systems. The challenges in motion planning and control aren’t about imposing order, but about cultivating an environment where these robots can navigate complexity and, ultimately, refine their own performance. It’s a prophecy of failure, perhaps, but also of resilient growth.

What’s Next?

The pursuit of collaborative continuum robots inevitably reveals a familiar pattern. The field seeks modularity, distributed intelligence, and adaptable architectures – all attempts to forestall the inevitable consolidation of failure. Each additional arm, each degree of freedom, does not diminish systemic risk; it merely expands the surface area upon which complexity can accrue. These robots will not ‘solve’ a problem so much as relocate it, embedding it within a network of dependencies.

The current emphasis on data-driven modeling and reinforcement learning, while promising, addresses symptoms, not the underlying condition. The system learns to compensate for its own inherent fragility, becoming ever more adept at navigating the precipice of instability. Control, ultimately, is not mastery, but skillful postponement. The more intelligently these robots adapt, the more exquisitely they will fail when faced with genuinely novel circumstances.

The trajectory suggests a future not of robust, independent agents, but of exquisitely intertwined dependencies. These robots will not be tools, but ecosystems – delicate, self-organizing, and ultimately, transient. The challenge, then, is not to build a system that lasts, but to design one that fails gracefully – a paradox the field seems destined to confront, again and again.

Original article: https://arxiv.org/pdf/2601.10721.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Clash Royale Best Boss Bandit Champion decks

- Vampire’s Fall 2 redeem codes and how to use them (June 2025)

- World Eternal Online promo codes and how to use them (September 2025)

- Best Arena 9 Decks in Clast Royale

- Country star who vanished from the spotlight 25 years ago resurfaces with viral Jessie James Decker duet

- M7 Pass Event Guide: All you need to know

- Mobile Legends January 2026 Leaks: Upcoming new skins, heroes, events and more

- Kingdoms of Desire turns the Three Kingdoms era into an idle RPG power fantasy, now globally available

- Solo Leveling Season 3 release date and details: “It may continue or it may not. Personally, I really hope that it does.”

- JJK’s Worst Character Already Created 2026’s Most Viral Anime Moment, & McDonald’s Is Cashing In

2026-01-19 07:39