Author: Denis Avetisyan

A new autonomous agent leverages the power of natural language to navigate vast scientific literature and accelerate the discovery of materials with targeted properties.

This work introduces the Materials Knowledge Navigation Agent (MKNA), demonstrating an automated workflow for identifying high Debye temperature materials via knowledge retrieval and computational modeling.

Traditional materials discovery relies heavily on expert intuition and computationally intensive simulations, creating a bottleneck in the development of advanced technologies. This work introduces the Materials Knowledge Navigation Agent (MKNA), a language-driven system designed to translate scientific intent into automated workflows for materials exploration. By autonomously extracting knowledge from both literature and databases, MKNA successfully rediscovered known ultra-stiff materials and proposed previously unreported, thermodynamically stable Be-C-rich compounds with high [latex]\Theta_D[/latex] values. Could this approach usher in a new era of autonomous, language-guided materials science, accelerating the pace of innovation across diverse fields?

The Enduring Challenge of Materials Discovery

The development of new materials has historically been a protracted and costly endeavor, largely dependent on synthesizing and testing numerous candidate compounds in a process akin to informed guesswork. This ‘trial-and-error’ approach demands significant time, labor, and resources, as researchers must physically create and characterize materials, often with limited predictive power regarding their ultimate properties. The sheer volume of potential material combinations – encompassing diverse elements and their stoichiometries – creates a vast chemical space that is practically impossible to explore comprehensively through purely experimental means. Consequently, the pace of materials innovation is often constrained, hindering advancements in fields ranging from energy storage and aerospace engineering to biomedicine and sustainable technologies. This reliance on physical experimentation not only limits the speed of discovery but also necessitates substantial investment in specialized equipment and highly skilled personnel, creating a significant barrier to entry for many researchers and institutions.

Despite the transformative potential of computational materials science, predicting material properties relies heavily on the fidelity of the theoretical models employed-models which often incorporate approximations and simplifications that introduce inaccuracies. These models, ranging from density functional theory to molecular dynamics, demand significant computational resources, particularly when simulating complex materials or exploring extended timescales. The inherent trade-off between accuracy and computational cost limits the scope of simulations; a highly accurate calculation for even a modest system can be prohibitively expensive, while faster, less accurate methods may yield unreliable predictions. This challenge necessitates ongoing development of more efficient algorithms, improved force fields, and the exploitation of high-performance computing infrastructure to effectively navigate the vast landscape of potential materials and accelerate discovery.

The pursuit of materials boasting high Debye temperatures presents a considerable obstacle in advanced materials science. This temperature, indicative of the maximum vibrational frequency of atoms within a material, directly correlates with its ability to withstand extreme conditions and maintain structural integrity at elevated temperatures – qualities essential for applications ranging from jet engine components to high-power electronics. Traditional methods for identifying such materials are often hampered by the sheer number of potential chemical compositions and crystal structures, requiring extensive experimentation and characterization. Computational approaches, while offering a potential shortcut, are frequently limited by the accuracy of interatomic potentials and the computational expense of simulating atomic vibrations, making the reliable prediction of high Debye temperatures a persistent and demanding challenge in the field.

The sheer scale of possible materials presents a formidable obstacle to innovation. Combinatorial chemistry suggests an astronomical number of potential compounds-far exceeding what can be realistically synthesized and tested using conventional methods. This vast ‘chemical space’ isn’t simply large, but also highly complex, with subtle changes in composition or structure potentially leading to drastically different properties. Current materials discovery approaches, even those incorporating computational screening, often rely on searching limited subsets of this space, guided by intuition or existing knowledge. Consequently, materials with truly novel and potentially groundbreaking characteristics may remain hidden, as systematic exploration is hampered by computational limitations and the prohibitive cost of physical experimentation. Addressing this challenge necessitates developing more efficient search algorithms and predictive models capable of intelligently navigating this immense landscape and prioritizing promising candidates for further investigation.

MKNA: An Autonomous Agent for Intelligent Materials Design

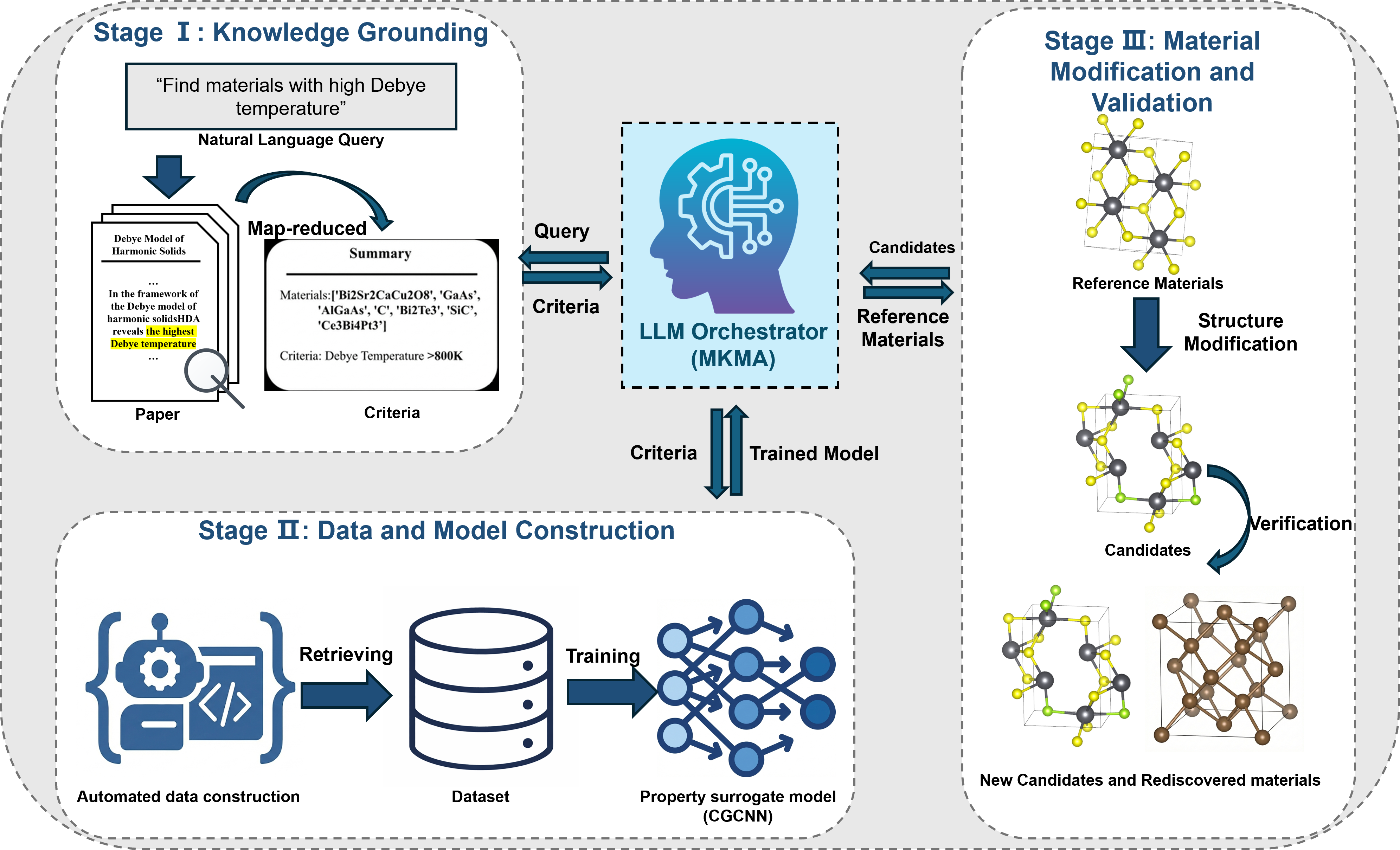

The Materials Knowledge Navigation Agent (MKNA) is an artificial intelligence framework developed to accelerate the process of materials discovery through automation. This system moves beyond traditional, manual methods of materials research by employing AI to autonomously propose, evaluate, and refine potential material compositions and structures. MKNA aims to reduce the time and resources required to identify novel materials with desired properties by integrating computational tools and knowledge databases into a self-directed research cycle. The framework is designed to operate without constant human intervention, enabling continuous exploration of the materials space and potentially uncovering materials that would be difficult to find through conventional approaches.

The Materials Knowledge Navigation Agent (MKNA) employs a LangChain orchestration layer to facilitate communication and data exchange between diverse computational resources and knowledge repositories. This integration allows MKNA to access and utilize tools such as materials databases, quantum mechanical solvers, and machine learning models without requiring bespoke interfaces. LangChain manages the sequential and parallel execution of these tools, handling data transformations and ensuring compatibility between different input/output formats. Specifically, it enables the agent to chain together multiple operations-for example, querying a database, performing a calculation on the retrieved data, and then using the result as input for a subsequent machine learning prediction-to achieve complex materials design tasks.

The Materials Knowledge Navigation Agent (MKNA) employs GPT-5-mini as its primary reasoning engine for processing materials data and directing research. This large language model facilitates semantic interpretation of scientific literature, databases, and computational results, allowing MKNA to identify relevant relationships and patterns. GPT-5-mini’s capabilities enable the agent to formulate testable hypotheses regarding material properties and performance, and subsequently guide computational experiments or simulations to validate these predictions. The model’s reasoning process underpins MKNA’s autonomous exploration of the materials space, iteratively refining its understanding and focusing investigation on promising candidates.

The Materials Knowledge Navigation Agent (MKNA) employs an autonomous agent framework to enable iterative scientific decision-making without direct human intervention. This framework incorporates components for task planning, tool utilization, and observation analysis. Specifically, MKNA utilizes a loop consisting of hypothesis generation, computational prediction via integrated tools, and subsequent analysis of results to refine its search strategy. This cyclical process allows the agent to independently explore the materials space, assess the validity of its hypotheses, and converge on potentially promising materials candidates. The overarching framework manages this process, coordinating the various computational tools and knowledge sources to achieve automated materials discovery.

![Comparison of Debye temperature distributions reveals that MKNA-modified stable candidates exhibit a significant shift towards ultra-stiff regimes ([latex]\sim1500-1700 K[/latex]), identifying previously unreported Be-C-rich frameworks while aligning with literature-derived evidence supporting a grounded threshold of [latex]\\Theta_{D} > 800 K[/latex] and expanding beyond the broad range ([latex]\\sim100-2200 K[/latex]) observed in the Materials Project database.](https://arxiv.org/html/2602.11123v1/DebyeT_Comparision.png)

Building the Knowledge Base: Data Mining and Predictive Modeling

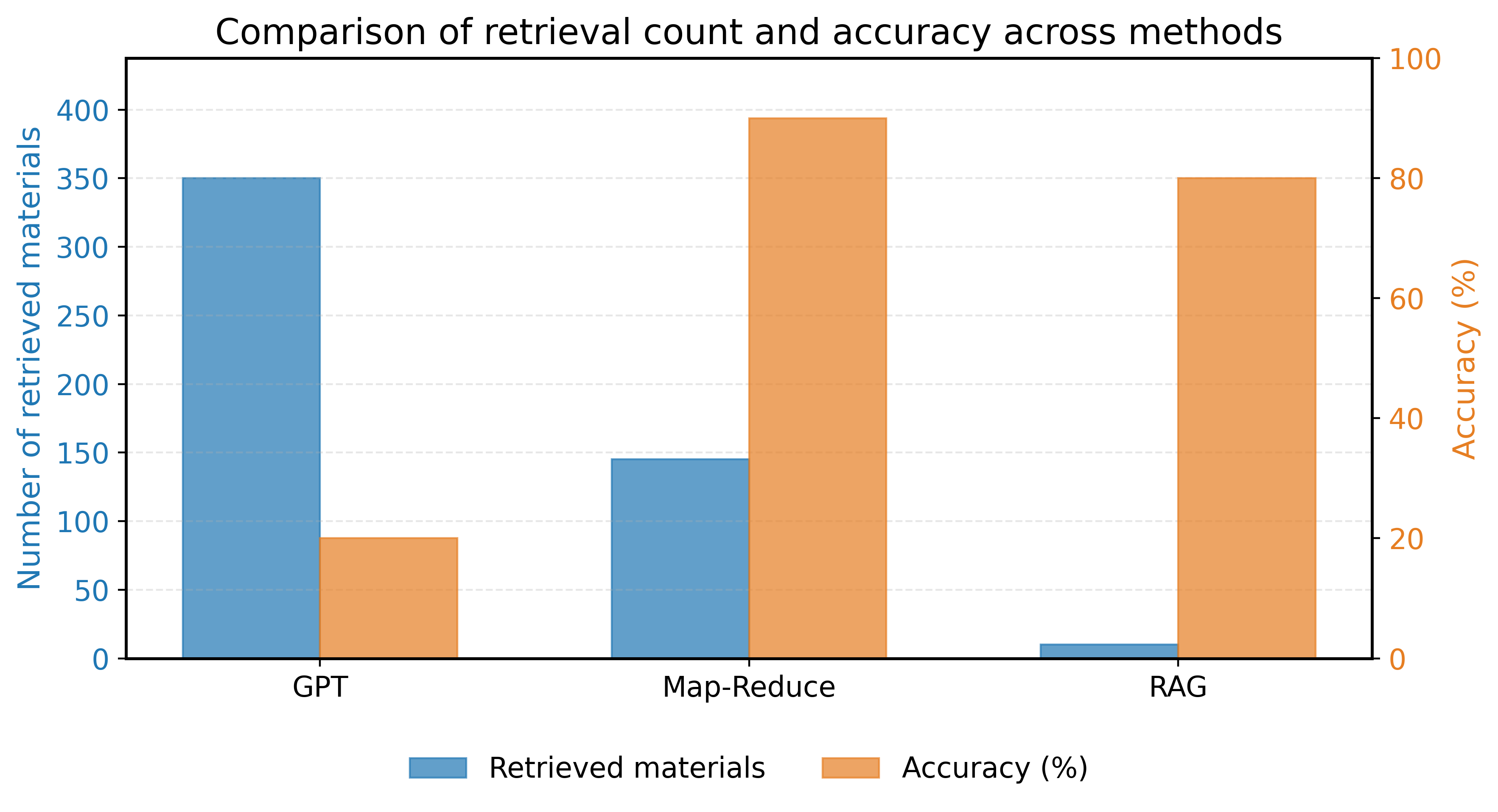

MKNA utilizes literature mining to systematically extract structured data from published scientific literature. This process employs a Map-Reduce Extraction methodology, enabling the processing of large volumes of text to identify and categorize material properties, compositions, and relationships. The extracted data is then formatted into a structured knowledge base, facilitating computational analysis and reasoning. This approach allows MKNA to leverage existing scientific knowledge, supplementing data obtained from computational methods and high-throughput calculations, and providing a broader context for materials property prediction.

The enrichment of the agent’s understanding of material properties and relationships is achieved through the aggregation of data extracted from scientific literature and computational predictions. This data encompasses a broad range of material characteristics, including chemical composition, crystal structure, and associated physical properties. By establishing connections between these attributes, the agent can infer properties of novel materials or predict behavior under specific conditions. This interconnected knowledge base facilitates scientific reasoning by enabling the agent to identify patterns, formulate hypotheses, and evaluate the validity of predictions based on established material science principles. The agent’s capacity to leverage these relationships is central to its ability to perform tasks requiring material selection, design optimization, and property prediction.

MKNA incorporates computationally predicted material properties, supplementing data extracted from scientific literature. Predictions are generated using graph neural networks, specifically the CGCNN and M3GNet methodologies, to estimate material characteristics. Performance of these predictive models was evaluated on a held-out test set, yielding a Root Mean Squared Error (RMSE) of 247 K and an R-squared value of 0.68. These metrics indicate the predictive capability of the integrated computational methods in estimating material properties, providing a quantitative assessment of their accuracy and reliability.

High-throughput Density Functional Theory (DFT) calculations are a primary source of training data for MKNA. These workflows systematically compute material properties across a broad compositional space, leveraging existing large-scale databases such as the Materials Project, AFLOW, OQMD, and NOMAD to maximize data availability and minimize computational cost. Data obtained from these sources includes, but is not limited to, energy, band structure, and atomic forces. The resulting datasets are essential for training machine learning models used in property prediction and materials discovery, providing a foundational level of accuracy against which literature-derived data can be validated.

Exploring Chemical Space: Structure Modification and Validation

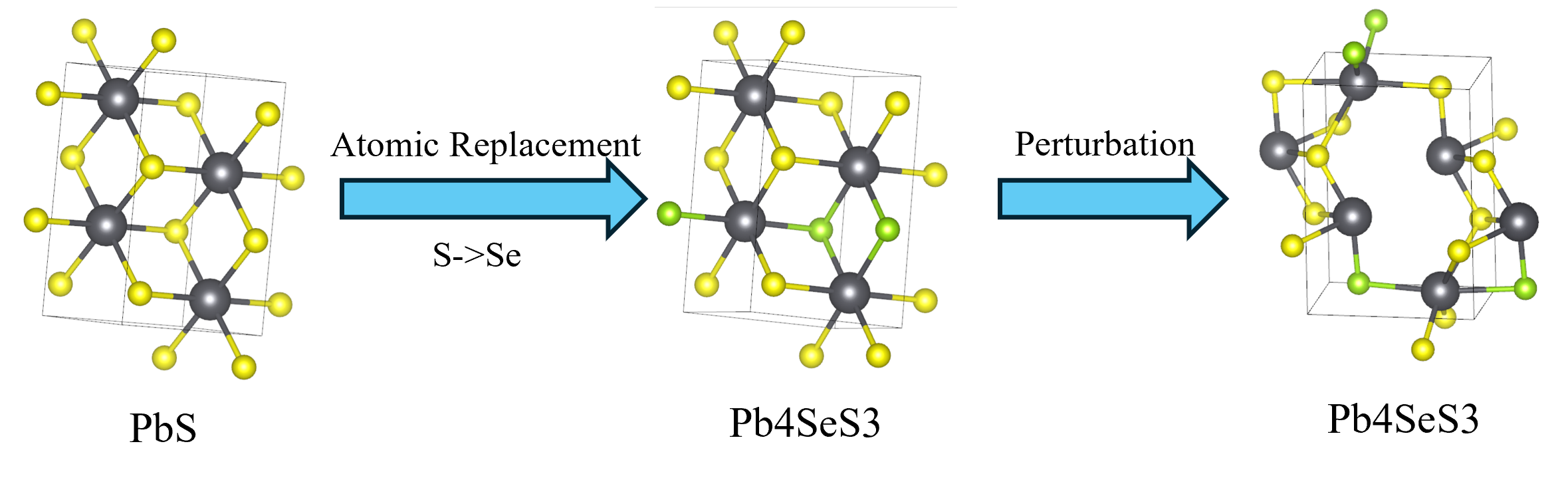

Material Knowledge Nucleation Agent (MKNA) employs both substitutional and perturbative techniques to systematically alter existing material structures. Substitution involves replacing atoms within a lattice with different elements, while perturbation introduces minor structural changes such as strain or displacement. These modifications are not random; the agent utilizes algorithms to intelligently explore structural variations based on predefined parameters and objectives. The process allows for the creation of numerous candidate materials from a single initial structure, facilitating rapid exploration of chemical space and the potential discovery of novel compounds with desired properties. This active modification approach is a core component of MKNA’s materials design workflow, enabling iterative refinement and optimization of material structures.

Material Knowledge Network Agents (MKNA) utilize established structure-property relationships to inform structural modifications. These relationships define how alterations to a material’s composition or atomic arrangement impact its macroscopic properties, such as thermal conductivity, mechanical strength, and Debye temperature. The agent’s understanding, derived from existing datasets and predictive models, allows it to prioritize modifications likely to yield desired property outcomes. Specifically, the agent assesses how changes in bond lengths, angles, and atomic species will affect phonon propagation – a key determinant of Debye temperature – and guides the modification process accordingly. This targeted approach minimizes computational cost by focusing on potentially viable candidate materials, rather than exploring modifications randomly.

Candidate materials generated through structural modification are assessed for Debye temperature using predictive modeling techniques. Materials failing to meet predefined stability criteria – specifically, an energy per atom exceeding 0.05 eV/atom – are discarded. Those that do satisfy this criterion may undergo further computational refinement to improve predictive accuracy and validate structural integrity. This tiered evaluation process prioritizes materials exhibiting both desired thermal properties and inherent structural stability, ensuring the viability of candidates for subsequent investigation.

Beryllium-carbon (Be-C) frameworks are investigated as candidate materials for achieving high Debye temperatures due to their predicted structural properties. Utilizing the MKNA (Material Knowledge and Neural Network Agent) predictive capabilities, these frameworks are evaluated based on elasticity-derived Debye temperature calculations. Validation demonstrates a high degree of accuracy, with the calculated Debye temperatures exhibiting an error of less than 5% when compared to established literature values for similar compounds. This level of predictive accuracy supports the exploration of Be-C frameworks as viable high-temperature materials and confirms the efficacy of MKNA in guiding material discovery.

Towards Accelerated Materials Innovation: A New Paradigm

Materials discovery is undergoing a fundamental transformation with the advent of Machine-Knowledge-Navigation Acceleration, or MKNA. Historically, the development of new materials has relied heavily on serendipity and iterative experimentation – a process often described as trial-and-error. MKNA, however, represents a shift towards intelligent exploration, leveraging the power of machine learning algorithms to predict material properties and guide the design process. This proactive approach moves beyond simply testing existing compounds; instead, it allows researchers to computationally screen vast chemical spaces, identify promising candidates, and prioritize experimental efforts. By systematically navigating the complex landscape of materials science, MKNA drastically reduces the time and resources traditionally required to uncover novel materials with targeted functionalities, paving the way for breakthroughs in diverse fields like renewable energy and advanced electronics.

Materials development traditionally involves a cyclical process of design, fabrication, and testing, often requiring significant time and resources. Machine Knowledge-guided Navigation of the Atomic (MKNA) paradigm drastically accelerates this process by automating crucial steps within that cycle. Through robotic experimentation and data-driven analysis, MKNA minimizes the need for manual intervention, enabling rapid prototyping and characterization of materials. This automation not only shortens the time required to discover novel materials, but also substantially lowers the associated costs by reducing labor and material waste, paving the way for more efficient and economical innovation across diverse fields like energy storage and advanced electronics.

The potential of materials knowledge networks and automated experimentation lies in the creation of materials specifically designed for targeted applications. This isn’t simply about discovering new materials, but crafting substances with precisely tuned properties – enhanced conductivity for next-generation electronics, improved energy density for advanced batteries, or increased efficiency in solar energy conversion. By leveraging computational modeling and high-throughput experimentation, researchers can systematically explore vast compositional spaces, identifying materials optimized for performance characteristics previously unattainable. This tailored approach promises breakthroughs across diverse fields, accelerating innovation in areas ranging from sustainable energy technologies to lightweight structural materials and beyond, ultimately offering solutions to pressing global challenges.

The trajectory of materials knowledge and new applications (MKNA) is set to be significantly bolstered by a concentrated effort towards robust experimental validation. Current research endeavors prioritize bridging the gap between computational prediction and real-world performance, aiming to create a self-correcting cycle where experimental data directly informs and refines predictive models. Simultaneously, the scope of MKNA is being broadened to address increasingly complex materials systems – encompassing multi-component alloys, heterogeneous interfaces, and materials exhibiting emergent properties. This expansion necessitates the development of advanced algorithms capable of navigating vast compositional spaces and accurately predicting the behavior of these intricate materials, ultimately accelerating the discovery of solutions for pressing technological challenges in areas like sustainable energy and advanced electronics.

The pursuit of accelerated materials discovery, as demonstrated by the Materials Knowledge Navigation Agent (MKNA), necessitates a rigorous focus on fundamental principles. MKNA’s ability to navigate complex scientific literature and connect natural language descriptions to computational modeling mirrors a holistic understanding of interconnected systems. This echoes Blaise Pascal’s observation: “All of humanity’s problems stem from man’s inability to sit quietly in a room alone.” While seemingly unrelated, the quote underscores the importance of focused inquiry and distilling core truths – a principle central to MKNA’s design. The agent’s success hinges on stripping away extraneous information to identify materials exhibiting desired properties, like high Debye temperatures, demonstrating that simplicity often unlocks the most profound insights.

Beyond the Horizon

The demonstration of an autonomous agent navigating the materials knowledge space is not, of course, a solution. It is merely a refined articulation of the problem. The agent, while adept at connecting natural language queries to computational predictions, remains fundamentally reliant on the existing corpus of materials data – a dataset inherently biased towards explored chemistries and structures. The true challenge lies not in accelerating the search within the known, but in expanding the boundaries of what is knowable. Future iterations must grapple with the implicit assumptions embedded within the training data and develop mechanisms for genuine novelty – for venturing confidently beyond the well-trodden paths.

Furthermore, the focus on a single property – Debye temperature, while a useful benchmark – risks creating a system optimized for a narrow objective. Materials are rarely judged on isolated characteristics. Their utility arises from a complex interplay of properties, often contradictory. A more holistic approach requires agents capable of balancing competing demands, of understanding the trade-offs inherent in materials design. This necessitates a shift from predictive modeling to generative design, where the agent actively proposes novel compositions and structures, guided not by a single metric, but by a nuanced understanding of functional requirements.

The architecture, at present, functions as a sophisticated filter. But good architecture is invisible until it breaks, and only then is the true cost of decisions visible.

Original article: https://arxiv.org/pdf/2602.11123.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Clash of Clans Unleash the Duke Community Event for March 2026: Details, How to Progress, Rewards and more

- Gold Rate Forecast

- Star Wars Fans Should Have “Total Faith” In Tradition-Breaking 2027 Movie, Says Star

- KAS PREDICTION. KAS cryptocurrency

- Christopher Nolan’s Highest-Grossing Movies, Ranked by Box Office Earnings

- eFootball 2026 Jürgen Klopp Manager Guide: Best formations, instructions, and tactics

- Jujutsu Kaisen Season 3 Episode 8 Release Date, Time, Where to Watch

- Jason Statham’s Action Movie Flop Becomes Instant Netflix Hit In The United States

- Jessie Buckley unveils new blonde bombshell look for latest shoot with W Magazine as she reveals Hamnet role has made her ‘braver’

- How to download and play Overwatch Rush beta

2026-02-12 14:08