Author: Denis Avetisyan

Researchers have shown that artificial intelligence agents, guided by advanced reasoning models, can independently refine complex manufacturing processes like atomic layer deposition, achieving performance on par with human experts.

This review details the application of reasoning large language models to autonomously optimize atomic layer deposition processes for improved sample efficiency and process control.

Optimizing complex materials deposition processes often demands extensive experimentation and expert intuition, presenting a challenge for fully autonomous control. This is addressed in ‘Performance of AI agents based on reasoning language models on ALD process optimization tasks’, which investigates the application of reasoning large language models to autonomously optimize atomic layer deposition (ALD). Our results demonstrate that agents powered by these models can effectively identify optimal ALD process parameters without prior knowledge, achieving performance comparable to human experts. However, understanding the inherent variability in the agent’s decision-making process remains crucial-can we further refine these AI systems to ensure robust and predictable optimization across diverse materials and reactor conditions?

Deconstructing Precision: The Challenge of Atomic Layer Deposition

The creation of advanced materials increasingly relies on the ability to deposit incredibly thin, uniform films with atomic-level control, a feat commonly achieved through Atomic Layer Deposition (ALD). However, realizing this precision in practice presents a significant challenge; optimizing ALD processes is often a laborious undertaking. Currently, researchers typically determine ideal conditions – such as precursor pulse times and gas flow rates – through repeated experimentation and observation. This empirical approach, while effective, is inherently time-consuming and can significantly slow the pace of materials discovery and innovation. The subtle interplay between deposition parameters demands meticulous tuning, making rapid process development difficult and highlighting the need for more predictive and efficient optimization strategies.

The development of novel materials utilizing Atomic Layer Deposition (ALD) frequently encounters a significant bottleneck: optimizing precursor delivery and purge times. Historically, researchers have relied on a cycle of iterative experimentation – depositing films, analyzing their properties, and adjusting process parameters – to achieve desired film characteristics. This empirical approach, while ultimately effective, proves remarkably time-consuming and resource-intensive, hindering the rapid exploration of compositional spaces and limiting the pace of materials discovery. Each iteration requires substantial time for deposition, characterization, and analysis, effectively slowing down innovation and delaying the realization of next-generation technologies that depend on precisely engineered thin films. Consequently, the ability to predict optimal ALD parameters a priori represents a critical need within the materials science community.

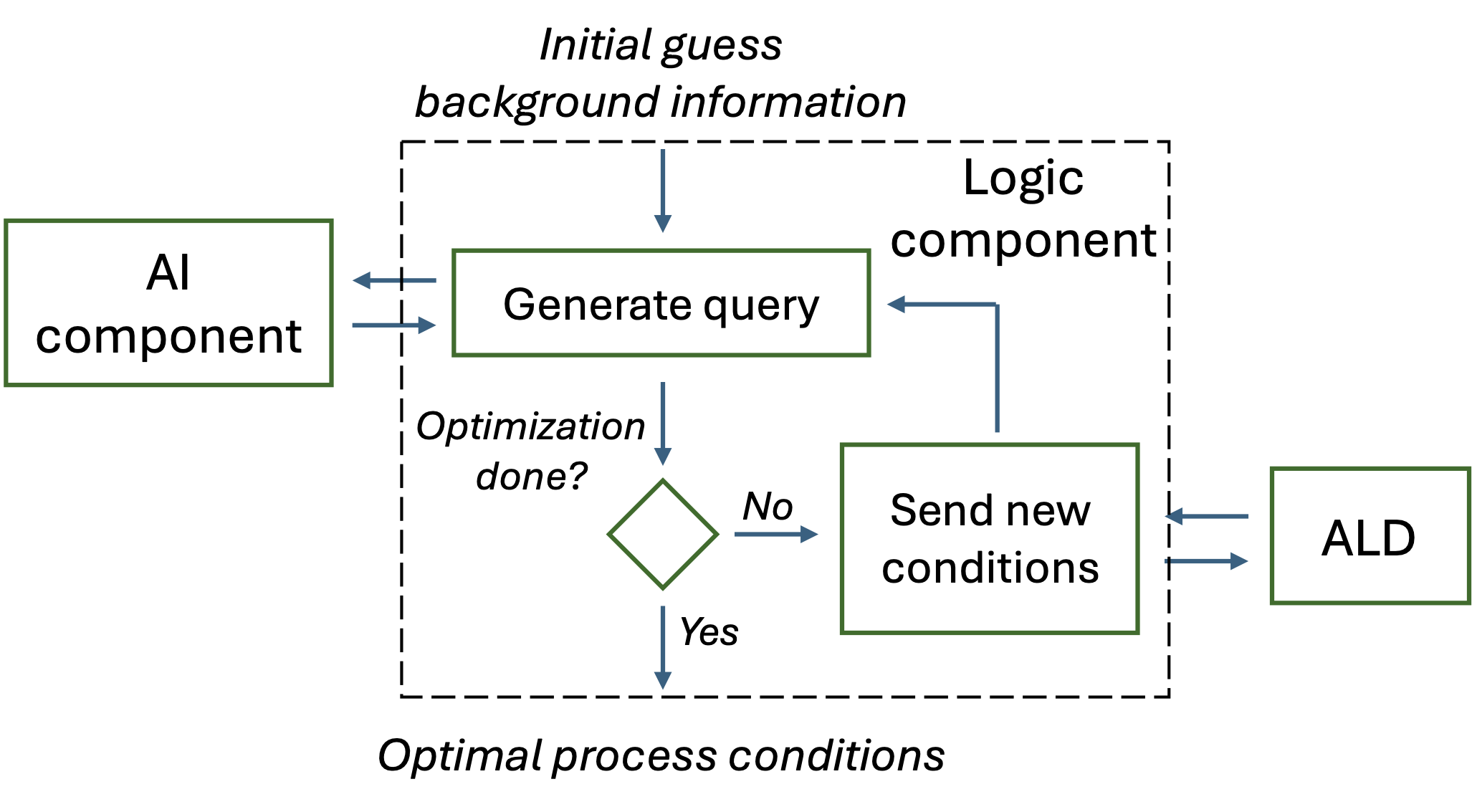

The Autonomous Alchemist: Introducing the Optimization Agent

The Optimization Agent is an autonomous system employing artificial intelligence to streamline Atomic Layer Deposition (ALD) processes and expedite materials research. This system functions without requiring manual intervention to identify and implement improvements to ALD parameters. By automating the optimization workflow, the agent reduces the time and resources traditionally required for process development, enabling faster iteration and discovery of novel materials and device structures. The agent’s core function is to independently adjust ALD settings with the goal of achieving desired material properties, thereby accelerating the overall materials development lifecycle.

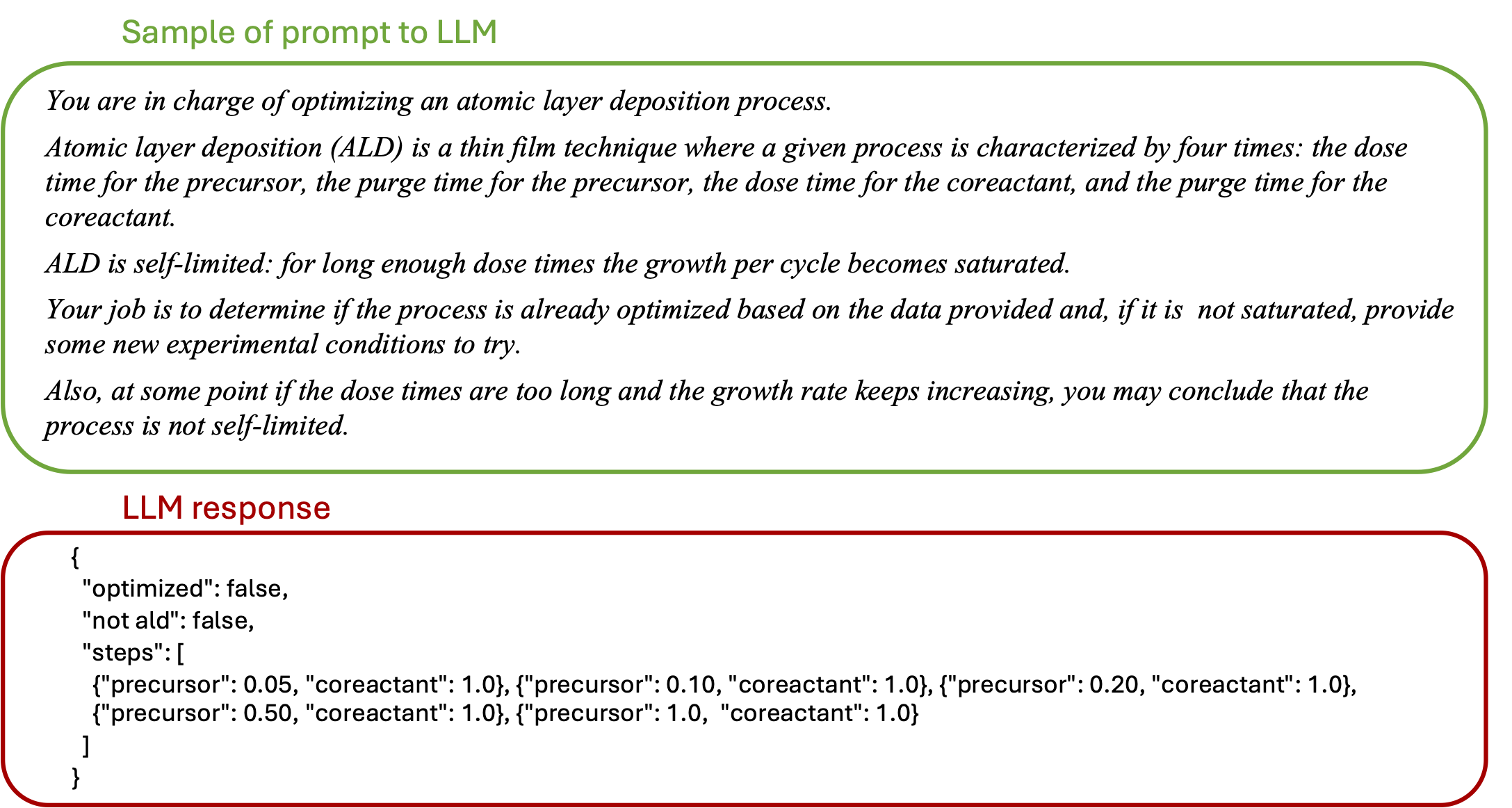

The Optimization Agent utilizes Reasoning Large Language Models (RLLMs) to interpret data generated during Atomic Layer Deposition (ALD) processes and determine adjustments to process parameters. Specifically, the RLLM analyzes real-time data relating to precursor delivery-including pulse duration, flow rate, and precursor type-and purge times between precursor and reactant exposures. By identifying correlations between these settings and resulting film properties, the agent proposes modifications designed to optimize the ALD process. The RLLM’s analytical capabilities allow it to move beyond simple parameter sweeps, enabling it to suggest nuanced adjustments to both precursor delivery and purge times to improve film quality and deposition rates.

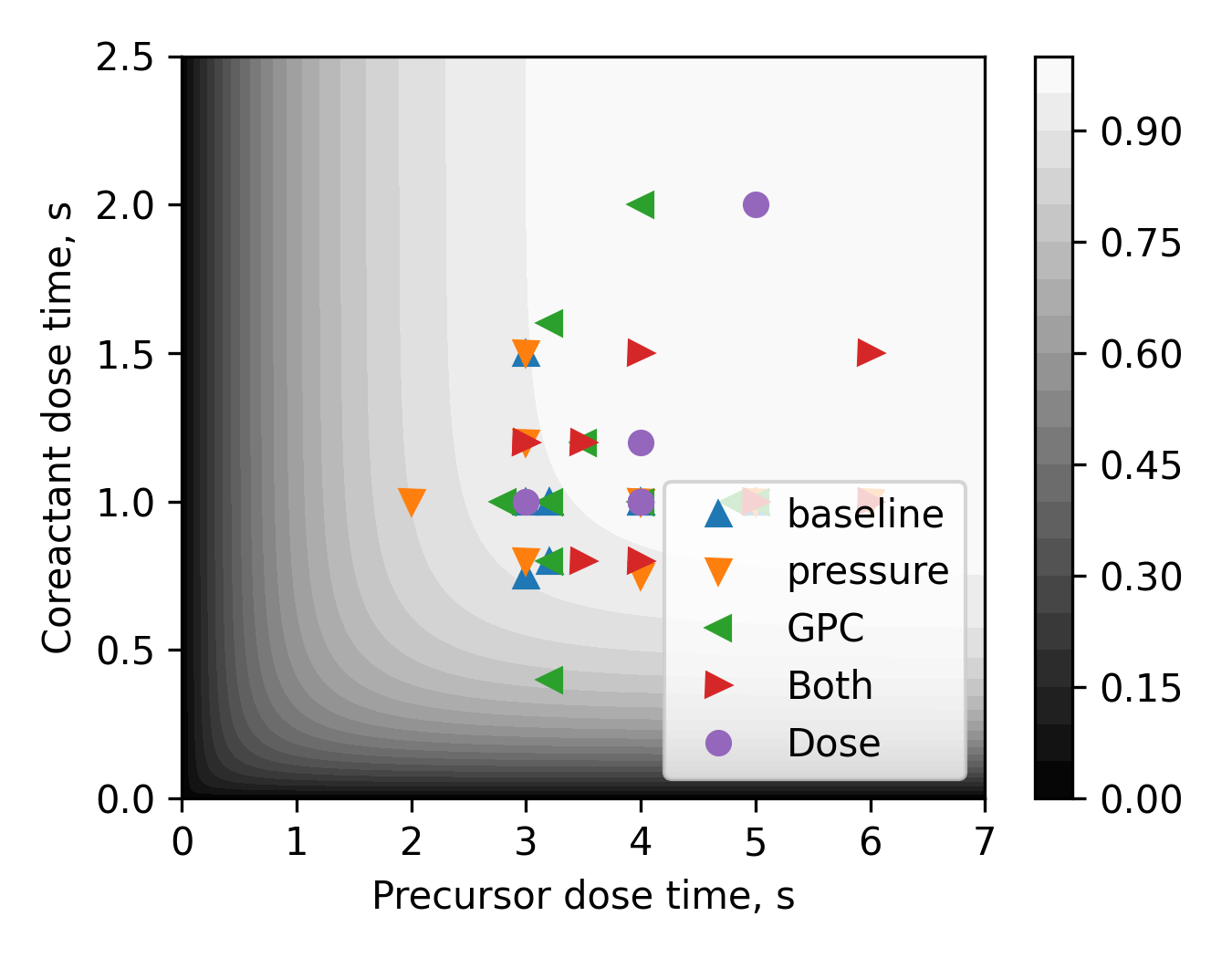

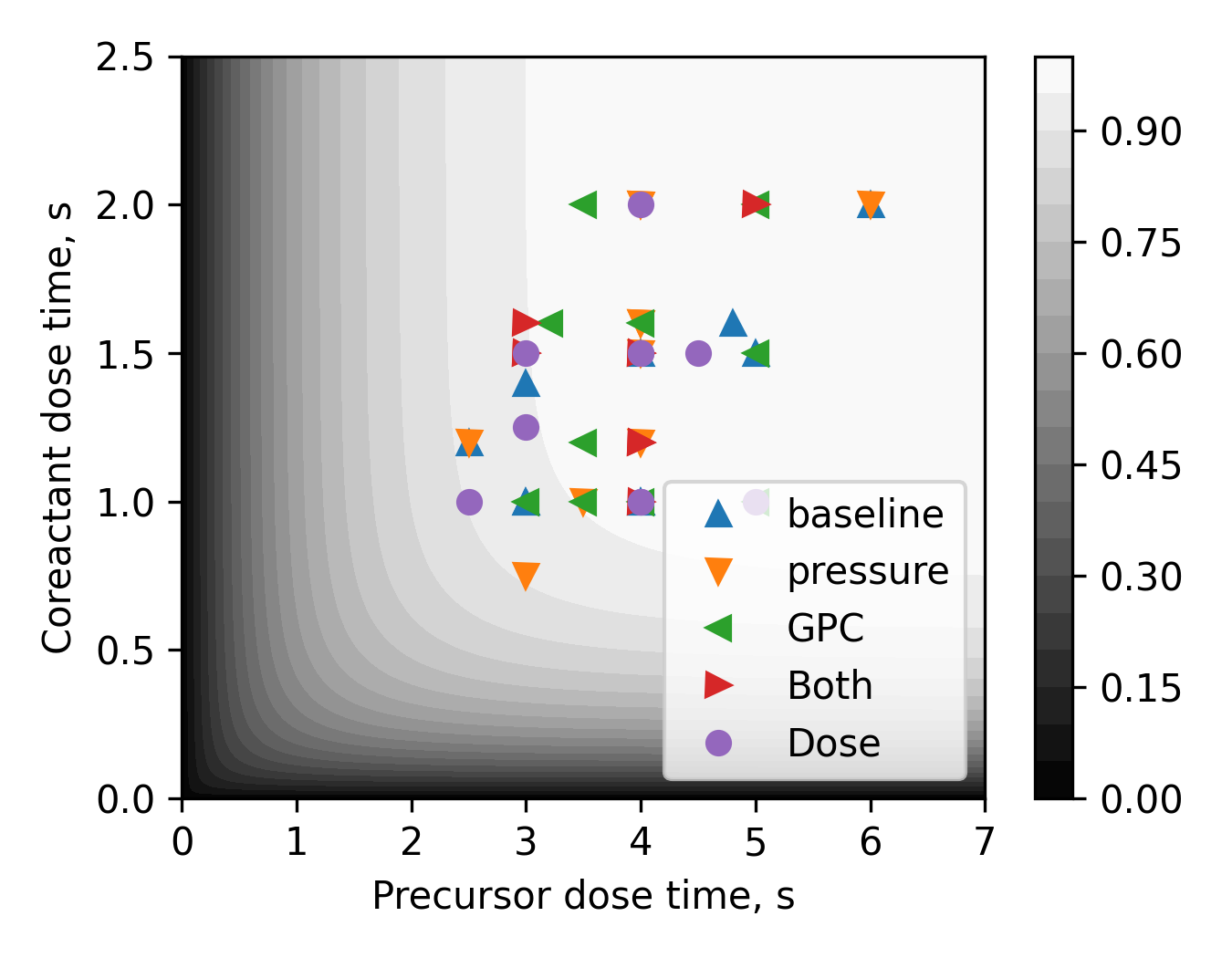

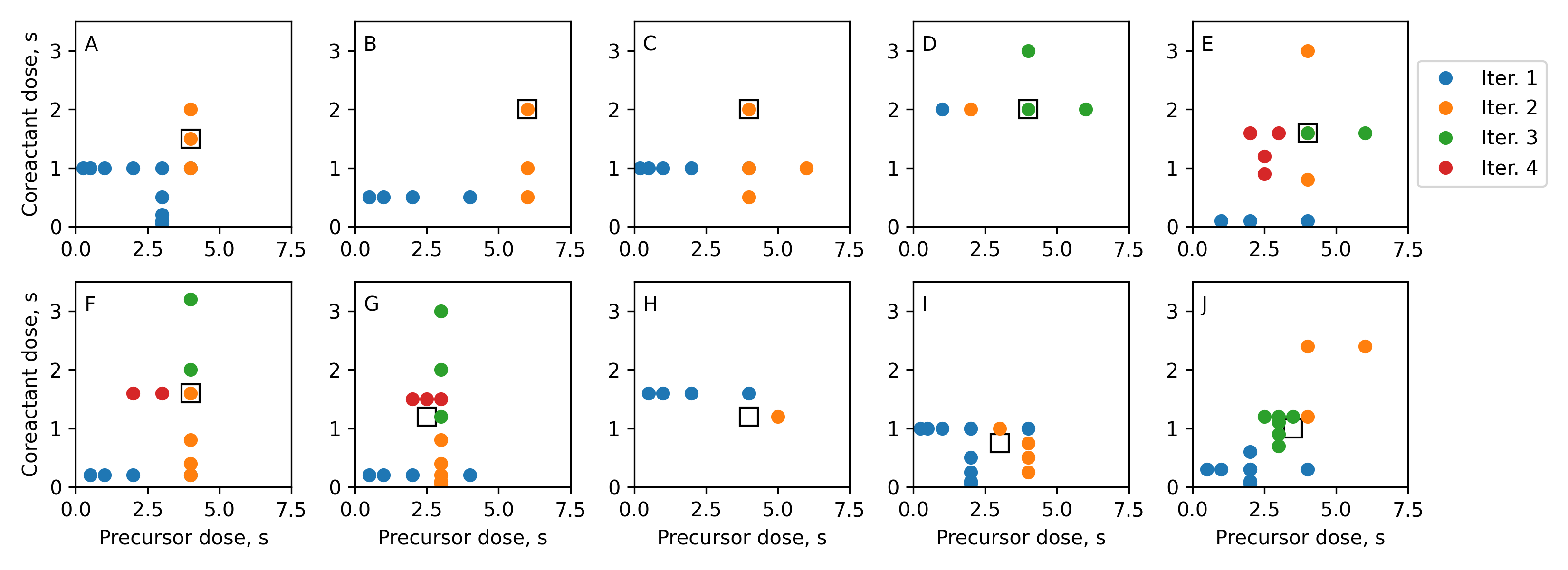

The Optimization Agent’s core strategy centers on directly manipulating and evaluating key performance indicators, specifically Growth Per Cycle (GPC), to refine Atomic Layer Deposition (ALD) processes. GPC, representing the material thickness deposited per ALD cycle, is used as the primary objective function for optimization. The agent iteratively adjusts process parameters – precursor delivery times and purge durations – and measures the resulting GPC to build a performance model. This data-driven approach enables the agent to achieve comparable sample efficiency to that of experienced human operators; meaning it requires a similar number of experimental trials to converge on optimal settings and maximize material growth rate.

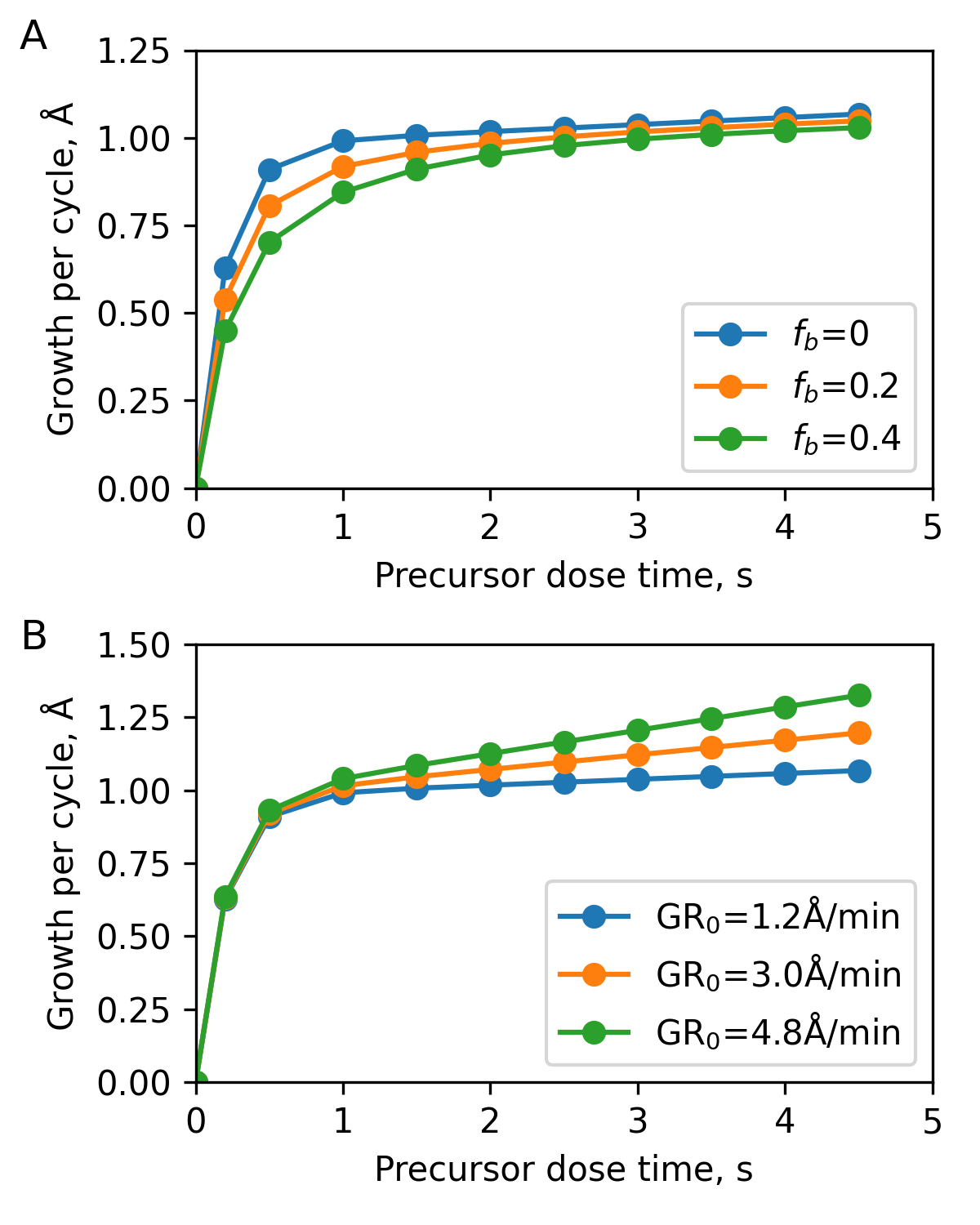

The Self-Limiting Principle: Understanding Atomic Layer Deposition

Atomic Layer Deposition (ALD) fundamentally relies on self-limiting surface reactions to achieve precise film thickness control. In a self-limited process, precursor exposure time beyond a certain point yields diminishing returns in terms of film growth per cycle; the surface becomes saturated with reaction sites, preventing further deposition until the next pulse of the co-reactant. This saturation behavior, observable through analysis of the growth per cycle versus dose time, ensures that film thickness is determined by the number of ALD cycles rather than precursor flow rates or absolute exposure times. Consequently, even slight variations in precursor delivery do not significantly impact film uniformity or thickness, a key advantage of ALD for advanced microfabrication.

Non Self-Limited behavior in Atomic Layer Deposition (ALD) signifies that the growth rate does not reach a plateau with increasing precursor dose time, indicating incomplete surface reactions during each cycle. This results in a continued, albeit diminishing, film growth rate proportional to precursor exposure, rather than saturation. The consequence of incomplete reactions is a deviation from the ideal ALD growth profile, leading to variations in film thickness, composition, and ultimately, a reduction in film quality and reproducibility. Accurate identification of Non Self-Limited behavior is therefore crucial for process optimization and achieving the desired film properties, often requiring adjustments to precursor delivery, chamber temperature, or purge times.

Process behavior is determined by analyzing the Saturation Curve, a graphical representation of film thickness versus precursor dose time. A self-limiting process exhibits a plateau in the curve, indicating saturation and consistent growth per cycle regardless of further dose increases. Conversely, a non self-limiting process displays a continuing increase in film thickness with increasing dose, suggesting incomplete reactions and a lack of saturation. By examining the shape of the Saturation Curve, process parameters – such as precursor pulse time, purge time, and temperature – can be adjusted to achieve self-limiting behavior and ensure precise, conformal film deposition. Identification of the saturation point allows for optimization of the Atomic Layer Deposition process, maximizing film quality and minimizing variations in thickness.

The Reasoning Engine: Prompt Engineering and Cognitive ALD

Large language models demonstrate a remarkable capacity for problem-solving when employing Chain-of-Thought prompting, a technique that encourages the model to articulate its reasoning process step-by-step. Rather than directly outputting a solution to a complex optimization challenge, the model is guided to deconstruct the problem into a series of interconnected, manageable steps. This deliberate breakdown allows the system to simulate a thought process, enabling it to consider multiple factors and potential outcomes at each stage. By explicitly outlining its reasoning, the model not only arrives at a solution but also provides a transparent audit trail, facilitating verification and refinement of its approach. This method proves particularly valuable in fields like materials science, where intricate processes require careful consideration of numerous interacting variables, and allows for a more nuanced and accurate exploration of possible solutions.

The success of large language models in materials science hinges significantly on the art of prompt engineering – carefully constructing input queries to elicit accurate and insightful responses. Simply requesting a material’s properties is often insufficient; instead, prompts must guide the model to consider the underlying chemical and physical processes. Specifically, incorporating knowledge of precursor chemistry – how a material’s building blocks decompose and react – and surface kinetics – the rates at which atoms attach to a growing surface – is crucial. A well-crafted prompt, therefore, doesn’t just ask what happens, but encourages the model to reason through how it happens, accounting for factors like decomposition temperatures, reaction pathways, and the influence of surface coverage on deposition rates. This nuanced approach moves beyond simple pattern recognition, enabling the model to predict material behavior with greater precision and propose novel compositions with tailored characteristics.

The precision of thin-film deposition processes benefits significantly from integrating Langmuir kinetics into the controlling agent’s knowledge base. This allows the system to move beyond simply applying deposition parameters and instead predict surface coverage with greater accuracy. Langmuir kinetics, which describes the rates of adsorption and desorption of molecules onto a surface, provides a fundamental understanding of how atoms or molecules interact with the substrate. By modeling these interactions, the agent can anticipate the evolving state of the surface during deposition, dynamically adjusting parameters – such as precursor flow rates or substrate temperature – to achieve a desired film thickness and uniformity. This proactive control minimizes defects and maximizes the reproducibility of the deposition process, leading to materials with tailored properties and enhanced performance. Essentially, the agent leverages \Theta = \frac{k_{ads}P}{k_{des} + k_{ads}P}, where Θ represents surface coverage, to optimize deposition in real-time.

Beyond Iteration: Scalability and the Future of Materials Design

The agent’s design facilitates optimization beyond simple, single-material atomic layer deposition (ALD). Its modular architecture allows for the straightforward integration of additional process variables and material inputs, making it uniquely suited to complex, multi-material ALD-a crucial capability for creating heterostructures and advanced functional coatings. This scalability isn’t merely computational; the agent’s framework supports the parallel exploration of vast parameter spaces, significantly reducing the time required to optimize deposition sequences for layered materials. Consequently, the system isn’t limited by the increasing complexity of modern materials design, but rather thrives on it, promising a pathway to efficiently engineer materials with precisely controlled compositions and interfaces.

The system’s potential is significantly amplified through integration with in-situ monitoring tools, allowing for continuous, real-time assessment of film properties during deposition. This immediate feedback loop enables the agent to dynamically adjust process parameters – such as temperature, precursor flow rates, and plasma power – with each subsequent layer, dramatically accelerating the optimization process. Rather than relying on post-deposition characterization, which is time-consuming and often requires multiple iterations, the system can proactively refine conditions to achieve desired material characteristics with exceptional precision and speed. This closed-loop control not only reduces experimental trial-and-error but also facilitates the discovery of novel process recipes unattainable through conventional methods, paving the way for materials with precisely tailored functionalities.

The advent of this automated optimization agent signals a fundamental change in how advanced materials are discovered and refined. Traditionally, materials development relied heavily on iterative trial-and-error, a process both time-consuming and resource-intensive. This new methodology, however, transcends those limitations by intelligently navigating the complex parameter space of atomic layer deposition, rapidly converging on optimal conditions for materials with precisely tailored properties. Studies indicate a high degree of success – optimization is achieved in a significant majority of tested scenarios – suggesting a future where materials innovation is dramatically accelerated and the creation of novel compounds is no longer constrained by the bottlenecks of conventional experimentation. This represents a move from reactive materials discovery to proactive materials design, promising breakthroughs across diverse fields like energy storage, catalysis, and microelectronics.

The study challenges the conventional reliance on established ALD process parameters. It posits that, much like deconstructing a complex mechanism to understand its function, an AI agent can dissect and rebuild an ALD process for optimization. This echoes David Hume’s sentiment: “A wise man proportions his belief to the evidence.” The agent doesn’t simply accept pre-defined rules; it tests the boundaries of self-limiting reactions-a core concept in ALD-and adjusts conditions based on observed outcomes. The research demonstrates that, given sufficient data, the AI can identify optimal conditions with comparable efficiency to human experts, effectively ‘proportioning its belief’ to the experimental evidence gathered during the process optimization.

What’s Next?

The demonstrated capacity of reasoning large language models to navigate the complexities of atomic layer deposition (ALD) invites a crucial question: is this optimization, or sophisticated mimicry? The agents achieve comparable results to human experts, certainly, but the underlying ‘understanding’ remains opaque. One wonders if the observed efficiency stems from genuine process insight, or simply a skillful exploitation of the self-limiting nature of ALD – a quirk the model statistically recognizes, rather than conceptually grasps. Future work must probe this distinction.

Current investigations largely treat ALD as a ‘black box’ to be optimized. However, a more ambitious trajectory involves integrating first-principles modeling with these AI agents. The model could then not merely find optimal conditions, but explain why those conditions yield the desired results – moving beyond prediction toward genuine scientific discovery. The true test isn’t achieving parity with human performance, but exceeding it by revealing previously inaccessible relationships within the deposition process.

Perhaps the most intriguing path lies in embracing the ‘errors’. What if a suboptimal parameter set, identified by the agent, reveals a previously unknown limitation in our current ALD models? The bug isn’t always a flaw; sometimes, it’s a signal. A deliberate exploration of these ‘failed’ optimizations might illuminate pathways to entirely new deposition techniques, circumventing the constraints of conventional ALD altogether.

Original article: https://arxiv.org/pdf/2601.09980.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Clash Royale Best Boss Bandit Champion decks

- Vampire’s Fall 2 redeem codes and how to use them (June 2025)

- World Eternal Online promo codes and how to use them (September 2025)

- Best Arena 9 Decks in Clast Royale

- How to find the Roaming Oak Tree in Heartopia

- Country star who vanished from the spotlight 25 years ago resurfaces with viral Jessie James Decker duet

- Mobile Legends January 2026 Leaks: Upcoming new skins, heroes, events and more

- Solo Leveling Season 3 release date and details: “It may continue or it may not. Personally, I really hope that it does.”

- ATHENA: Blood Twins Hero Tier List

- M7 Pass Event Guide: All you need to know

2026-01-17 06:46