Author: Denis Avetisyan

New research harnesses the power of generative artificial intelligence to create high-performance ship propellers tailored to specific needs.

Conditional Flow Matching, enhanced with data augmentation and CFD-validated surrogate models, enables the inverse design of optimized propeller geometries.

Achieving optimal designs in complex engineering applications often requires extensive iterative simulations and expert knowledge. This is addressed in ‘Generative Design of Ship Propellers using Conditional Flow Matching’, which explores a novel application of generative artificial intelligence for inverse design. By employing conditional flow matching-and augmenting data with less intensive surrogate models-the authors demonstrate the ability to generate diverse propeller geometries meeting specified performance criteria. Could this approach unlock new levels of efficiency and innovation in the design of marine propulsion systems and beyond?

The Constraints of Conventional Propeller Design

Propeller performance represents a substantial factor in overall ship efficiency, directly impacting fuel consumption and operational costs. However, realizing optimal designs through conventional methods proves remarkably challenging. Traditional propeller design relies on a cyclical process of physical model testing and iterative refinement, a procedure both time-consuming and financially demanding. Each design variation necessitates the construction of a physical prototype, followed by extensive testing to evaluate its hydrodynamic characteristics. This process is further complicated by the need for scale models, introducing potential inaccuracies when extrapolating results to full-scale vessels. Consequently, exploring the vast design space – variations in blade geometry, pitch distribution, and other critical parameters – becomes computationally expensive and limits the potential for truly innovative propeller designs that could significantly enhance maritime transport efficiency.

Conventional propeller design has historically depended on accumulated practical data and streamlined mathematical representations, a pragmatic approach that now presents significant limitations. While effective in the past, this reliance hinders a comprehensive investigation of potential designs, effectively narrowing the ‘design space’ available to engineers. Simplified models, though computationally efficient, often fail to capture the complex hydrodynamic interactions crucial for peak performance, and empirical data may not accurately reflect performance in novel operating conditions or with new materials. Consequently, truly innovative propeller geometries – those offering substantial gains in efficiency or reduced noise – can be overlooked, as traditional methods prioritize incremental improvements over bolder, potentially transformative designs. This constraint on exploration ultimately slows the advancement of marine propulsion technology.

Precisely forecasting how a propeller will perform under varied conditions necessitates highly detailed computational simulations, a process that strains even the most powerful computing infrastructure. These simulations account for the complex interplay of fluid dynamics, cavitation effects, and structural mechanics, requiring immense processing power and significant time to complete a single design iteration. Consequently, the traditional design cycle – involving simulation, analysis, physical model testing, and refinement – becomes protracted and expensive, effectively slowing down the development of more efficient and innovative propeller designs. This computational burden limits the number of designs that can be thoroughly evaluated, potentially causing promising configurations to be overlooked and hindering rapid prototyping efforts aimed at optimizing propeller performance for specific vessel requirements.

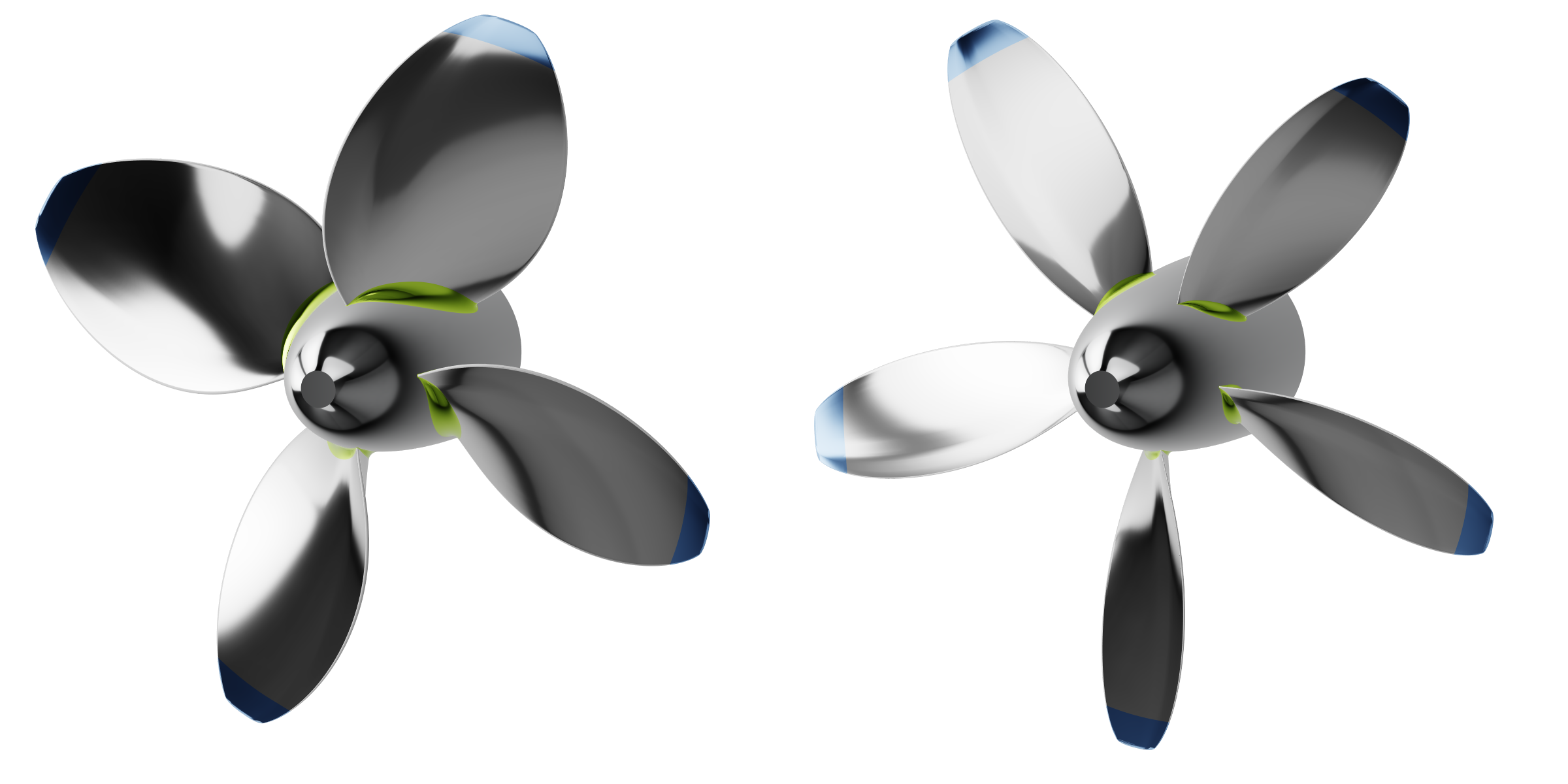

![The CFM model successfully generated three distinct propeller designs [latex]\mathbf{p}_{i}^{\text{Gen}}[/latex] optimized for a target load of [latex]\mathbf{l}^{\text{Target}}=(0.8,1.0,0.1)[/latex].](https://arxiv.org/html/2601.21637v1/images/propsForOneLabel.png)

From Iteration to Prediction: A Paradigm Shift

Simulation-Driven Design (SDD) addresses the inherent constraints of traditional propeller design, which historically relied heavily on empirical data from physical testing and iterative refinement. SDD leverages computational tools – specifically, numerical simulations – to predict propeller performance characteristics before physical prototypes are built. This predictive capability allows engineers to evaluate a broader range of design options, identify potential issues early in the development process, and optimize performance metrics such as thrust, efficiency, and cavitation resistance. The framework systematically integrates modeling, analysis, and optimization, enabling a more efficient and robust design cycle compared to purely experimental approaches.

Computational Fluid Dynamics (CFD) employs numerical methods to solve the Navier-Stokes equations, discretizing the fluid domain around the propeller into a mesh of control volumes. These methods calculate parameters such as pressure, velocity, and turbulence at each point in the mesh, allowing for the prediction of lift, drag, and thrust characteristics. The simulation process involves defining the propeller geometry, specifying the fluid properties (density, viscosity), establishing boundary conditions (inlet velocity, pressure), and selecting appropriate turbulence models (e.g., k-epsilon, k-omega SST). Post-processing of the CFD results yields detailed visualizations of flow patterns, including streamlines, pressure contours, and velocity vectors, enabling engineers to analyze the hydrodynamic performance and identify areas for design improvement.

Optimization algorithms are a core component of simulation-driven design, systematically searching the vast propeller design space to identify configurations that yield optimal performance. These algorithms, which include techniques like genetic algorithms, gradient-based methods, and surrogate modeling, automatically adjust design parameters – such as blade geometry, pitch distribution, and airfoil selection – within defined constraints. Each proposed design is then evaluated using computational fluid dynamics (CFD) simulations to quantify performance metrics like thrust, torque, efficiency, and cavitation inception. The algorithm uses these results to iteratively refine the design, converging on solutions that maximize the desired performance characteristics while satisfying specified operational requirements. This automated process enables the exploration of a much broader range of designs than would be feasible with traditional manual methods, leading to improved propeller performance and reduced design time.

Simulation-Driven Design significantly reduces development timelines and associated expenses by minimizing the need for iterative physical prototyping. Traditional propeller design relies heavily on building and testing multiple physical models to validate performance characteristics, a process that is both time-consuming and costly due to material expenses, manufacturing time, and testing infrastructure requirements. By leveraging computational tools to accurately predict propeller behavior, Simulation-Driven Design enables engineers to virtually explore a wider range of design options, identify potential issues early in the process, and refine designs without the need for physical builds until a highly optimized configuration is achieved. This reduction in prototype iterations translates directly into faster design cycles and substantial cost savings, particularly for complex or high-performance propeller applications.

Bridging Fidelity and Efficiency with Surrogate Models

Surrogate models offer a computationally efficient alternative to direct Computational Fluid Dynamics (CFD) simulations by approximating the relationship between design variables and performance metrics. Traditional CFD requires significant computational resources and time, particularly when evaluating numerous design iterations. Surrogate models, once trained on a limited dataset of high-fidelity CFD results, can predict performance characteristics for new designs with substantially reduced computational cost. This allows engineers to rapidly assess a wider range of design options during the preliminary stages of development, facilitating faster iteration and optimization cycles. The speed gained from employing surrogate models is crucial for complex designs where a single CFD run may take hours or days, effectively making comprehensive design space exploration impractical without approximation techniques.

Several techniques are utilized to construct surrogate models approximating the relationship between design variables and performance metrics. Response Surface Methodology (RSM) employs polynomial functions to model the response surface, providing a relatively simple and interpretable approximation. Kriging, a geostatistical technique, utilizes spatial correlation to predict values, offering greater accuracy but increased computational cost. Neural Networks, particularly Multi-Layer Perceptrons (MLPs), can model highly non-linear relationships and achieve high accuracy with sufficient training data, although they require substantial computational resources and careful hyperparameter tuning. The selection of an appropriate technique depends on the complexity of the relationship, the available computational resources, and the desired level of accuracy.

Surrogate models are constructed through a training process utilizing a deliberately limited dataset generated by high-fidelity Computational Fluid Dynamics (CFD) simulations. This initial dataset establishes the fundamental relationship between input design variables and the resulting performance metrics. Once trained, the surrogate model-whether based on techniques like Response Surface Methodology, Kriging, or Neural Networks-can rapidly predict performance characteristics for design points not included in the original training set. This capability significantly expands the scope of analysis beyond the computationally expensive high-fidelity simulations used for training, allowing for performance evaluation of a much larger design space with substantially reduced computational resources.

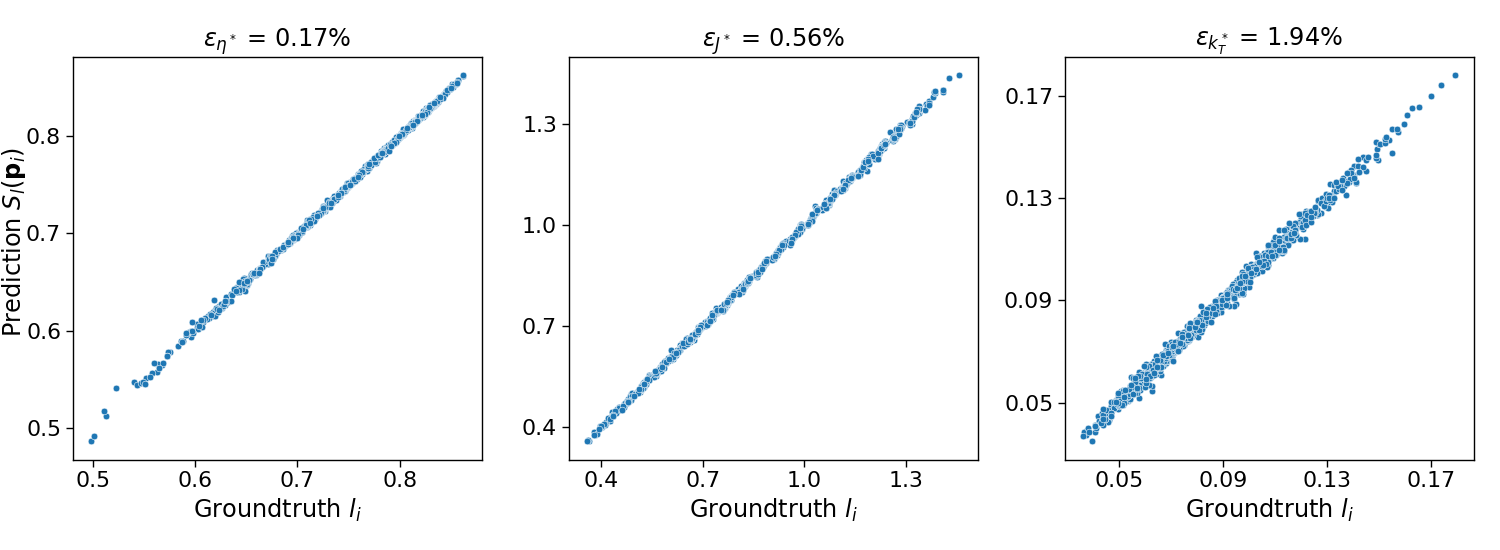

Validation of the surrogate models demonstrated a strong correlation between target and achieved performance labels. This agreement was quantitatively assessed using parity plots, which visually confirmed the model’s predictive capability across the range of design variables. Further analysis was conducted using Mean Relative Error (MRE), providing a numerical measure of the discrepancy between predicted and actual performance. The consistently low MRE values, as detailed in the study’s figures and tables, substantiate the reliability of the surrogate models in accurately representing the high-fidelity simulation data and enabling performance prediction with minimal error.

Analysis of Surrogate Model Error (MRE) revealed label-dependent accuracy, specifically concerning the performance metrics η, J, and kT*. Quantitative results, as presented in accompanying figures and tables, demonstrate that the predictive capability of the surrogate models was not uniform across all labels. The MRE values differed significantly, indicating a trade-off between computational efficiency gained through surrogate modeling and the level of accuracy achieved for each specific performance characteristic. This suggests that certain performance metrics are more readily approximated by the surrogate model than others, and that the choice of surrogate modeling approach or the level of training data may need to be adjusted based on the desired fidelity for each label.

The computational expense associated with high-fidelity simulations, such as Computational Fluid Dynamics (CFD), often limits the number of designs that can be evaluated during optimization studies. Surrogate models mitigate this limitation by providing a computationally efficient approximation of the performance characteristics, allowing for the evaluation of a significantly larger number of design candidates. This expanded design space exploration increases the probability of identifying optimal or near-optimal solutions that might be missed when using a limited set of computationally expensive simulations. Consequently, surrogate models facilitate more robust optimization algorithms and enable a more comprehensive understanding of the design space, including the identification of potential trade-offs and sensitivities.

Generative AI: Designing the Future of Propellers

Propeller design, traditionally a process of iterative refinement guided by human expertise, is undergoing a revolution through the application of generative artificial intelligence. These systems, employing techniques like Normalizing Flows and Conditional Flow Matching, autonomously create propeller geometries tailored to precise performance objectives. Rather than relying on pre-defined shapes, the AI learns the complex relationship between a propeller’s form and its hydrodynamic characteristics from extensive datasets of existing designs and performance data. This allows the algorithms to explore a vast design space, generating novel and potentially superior propellers that might not be conceived through conventional methods. The result is a shift from designing to a desired outcome to specifying the outcome and letting the AI generate the corresponding design, promising significant advancements in efficiency and performance for marine and aerial applications.

Generative artificial intelligence is demonstrating a remarkable capacity to transcend conventional propeller design limitations. These systems aren’t simply iterating on existing forms; they are learning the fundamental relationships between a propeller’s geometry and its hydrodynamic performance through exposure to extensive datasets of existing designs and associated performance metrics. This training allows the models to identify subtle, often non-intuitive, correlations that human designers might overlook. Consequently, the AI can generate entirely novel propeller geometries – shapes that would not typically arise from human ideation – yet demonstrably meet, or even exceed, specified performance targets. The result is a pathway toward propellers optimized for specific applications, pushing the boundaries of efficiency and potentially unlocking new levels of performance in marine and aerial propulsion systems.

The integration of Conditional Flow Matching with specialized parametric design tools, such as CAESES, represents a significant advancement in propeller design automation. This combination allows for the direct generation of three-dimensional geometries, defined by a set of customizable parameters, that are inherently optimized to meet specific performance objectives. Rather than relying on iterative design and analysis cycles, the system learns to map desired performance characteristics – like thrust, efficiency, or cavitation resistance – directly to the geometrical parameters defining the propeller’s shape. This streamlined process not only accelerates the design workflow but also facilitates the exploration of novel configurations that might be overlooked through traditional methods, pushing the boundaries of hydrodynamic performance and enabling the creation of highly efficient and tailored propeller designs.

The refinement of generative AI for propeller design benefits substantially from data augmentation techniques employing surrogate models, especially when training datasets are constrained. These surrogate models, acting as stand-ins for computationally expensive simulations, allow for the creation of synthetic data points that effectively expand the training set. This is particularly impactful when dealing with complex relationships between propeller geometry and performance characteristics – areas where a limited number of initial data points can hinder the learning process. Studies demonstrate that augmenting training data in this manner not only improves the accuracy of the generative models but also consistently outperforms baseline models relying solely on the original, limited dataset, fostering the creation of more efficient and innovative propeller designs.

The effectiveness of generative AI in propeller design is significantly boosted through data augmentation techniques. By strategically expanding the training dataset with intelligently generated variations, these models become more resilient to noise and uncertainty in real-world performance data. This process doesn’t simply increase the quantity of training examples; it enhances the quality of learning, enabling the generative models to better generalize beyond the initial dataset and explore a wider range of potential designs. Consequently, the resulting propellers exhibit improved performance characteristics and demonstrate greater adaptability to varying operational conditions, even when faced with incomplete or imperfect input data-a crucial benefit in the complex field of hydrodynamic design.

The pursuit of optimized ship propeller design, as detailed in this work, echoes a fundamental principle of efficient systems. It distills complex hydrodynamic requirements into a generative process, minimizing unnecessary variables to achieve desired outcomes. This aligns with Bertrand Russell’s observation: “The point of civilization is to lessen suffering.” Though seemingly distant, the reduction of drag and maximization of thrust-achieved through generative AI and surrogate modeling-lessens the energetic ‘suffering’ of propulsion. The method’s reliance on data augmentation, a refinement of the training dataset, further embodies this principle of paring down excess to reveal essential performance characteristics. Clarity is the minimum viable kindness.

The Horizon Recedes

The successful coupling of generative models with computational fluid dynamics, as demonstrated, is not a destination, but a clearing. The immediate benefit – a proliferation of viable propeller designs – obscures a deeper question. Namely, does this represent design, or merely efficient exploration of a parameter space already implicitly understood? The current reliance on CFD as a validation oracle feels… circular. The model learns to mimic established physics, codified in the simulation. True novelty will require disentangling performance characteristics from the geometric primitives themselves, a task demanding more than just larger datasets.

Further refinement must address the limitations inherent in surrogate models. Augmentation is a palliative, not a cure. The fidelity of the generative process remains tethered to the accuracy of the underlying approximation. The pursuit of ‘accuracy’ risks becoming an asymptote, chasing diminishing returns. A more fruitful avenue lies in embracing controlled imperfection – designs that deviate from established norms, but exhibit emergent properties not captured by conventional metrics.

Ultimately, the value proposition rests not on generating more designs, but on distilling design down to its essential elements. The code should be as self-evident as gravity. Intuition, after all, is the best compiler. This work offers a powerful tool, but the true challenge remains: to move beyond optimization, and toward a genuine understanding of hydrodynamic form.

Original article: https://arxiv.org/pdf/2601.21637.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- MLBB x KOF Encore 2026: List of bingo patterns

- eFootball 2026 Jürgen Klopp Manager Guide: Best formations, instructions, and tactics

- Overwatch Domina counters

- Brawl Stars Brawlentines Community Event: Brawler Dates, Community goals, Voting, Rewards, and more

- eFootball 2026 Starter Set Gabriel Batistuta pack review

- 1xBet declared bankrupt in Dutch court

- Gold Rate Forecast

- Clash of Clans March 2026 update is bringing a new Hero, Village Helper, major changes to Gold Pass, and more

- James Van Der Beek grappled with six-figure tax debt years before buying $4.8M Texas ranch prior to his death

- Magic Chess: Go Go Season 5 introduces new GOGO MOBA and Go Go Plaza modes, a cooking mini-game, synergies, and more

2026-02-01 10:24