Author: Denis Avetisyan

A new approach to robotic manipulation distributes force along contact lines, enabling more efficient and robust control for complex tasks.

This review introduces a Force-Distributed Line Contact (FDLC) model and explores its application with trajectory optimization techniques like iLQR and Model Predictive Control.

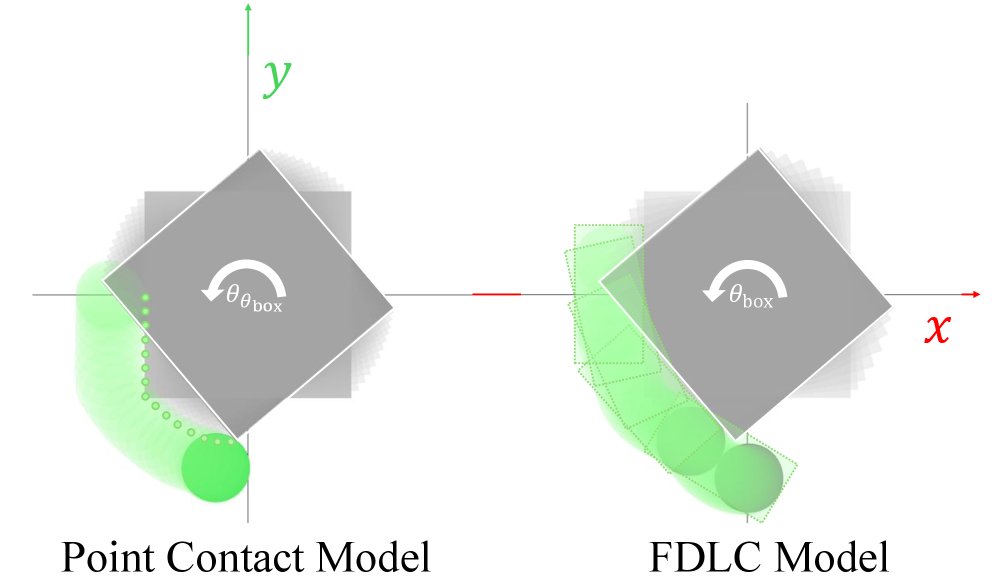

Achieving truly dexterous manipulation requires overcoming the limitations of simplified contact models. This paper, ‘Manipulation via Force Distribution at Contact’, introduces a novel approach to contact modeling-the Force-Distributed Line Contact (FDLC) model-and demonstrates its benefits for trajectory optimization in contact-rich tasks. By distributing forces along contact lines, the FDLC model generates more efficient and robust trajectories compared to traditional point contact methods, as validated through a box rotating task. Could this nuanced approach to contact modeling unlock new levels of adaptability and efficiency in robotic manipulation systems?

The Inevitable Friction of Reality

The future of automation extends far beyond the repetitive simplicity of pick-and-place operations; increasingly, robots are being asked to perform intricate, contact-rich manipulation tasks. Consider applications like assembling delicate electronics, preparing meals, or providing assistance in healthcare – scenarios demanding dexterity and adaptability beyond current capabilities. These aren’t merely movements from point A to point B, but complex interactions involving sustained contact, force control, and real-time adjustments to unpredictable external forces. Successfully navigating these challenges requires robots to not just grasp objects, but to skillfully feel and respond to them, opening doors to a wider range of applications and fundamentally altering how humans and robots collaborate in complex environments.

Conventional robotic control systems frequently depend on meticulously crafted models of the environment and the robot itself, yet these models falter when confronted with the unpredictable nature of physical contact. The real world introduces a multitude of uncertainties – slight variations in object position, unexpected surface friction, or unforeseen collisions – that deviate from the idealized assumptions embedded within these models. This discrepancy leads to inaccurate predictions of forces and motions, resulting in jerky movements, failed grasps, or even damage to the robot or its surroundings. While effective in highly structured environments, this reliance on precision proves problematic for tasks requiring nuanced interaction, such as assembling delicate components or manipulating deformable objects, highlighting the need for more adaptable control strategies.

The difficulty in achieving reliable robotic manipulation stems from a fundamental fragility when encountering real-world uncertainties. Current systems, often built upon precise mathematical models, falter when faced with even slight deviations – a slippery surface, an unexpected obstruction, or the subtle give of a deformable object. This lack of robustness doesn’t merely introduce occasional errors; it actively limits the complexity of tasks a robot can successfully perform. While a robot might reliably grasp a known object in a controlled environment, it struggles with the nuanced interactions required for assembly, delicate handling, or manipulation within cluttered scenes. Consequently, the potential for automation remains constrained, hindering the development of robots capable of truly versatile and adaptable manipulation skills.

Successfully navigating the complexities of real-world manipulation demands a fundamental change in robotic control strategies. Current systems often falter when faced with the unpredictable forces arising from contact with objects and environments; however, recent research emphasizes the necessity of systems capable of explicitly reasoning about these forces. Instead of rigidly following pre-programmed trajectories, robots must dynamically adapt their actions based on tactile feedback and force sensing. This involves developing algorithms that can not only measure contact forces, but also predict their evolution and utilize that information to adjust grip, posture, and movement in real-time. Such an approach promises to unlock a new level of robustness and dexterity, enabling robots to perform intricate tasks – from assembling delicate electronics to assisting in surgical procedures – with a reliability previously unattainable.

![Robot travel distances are shown for trajectories generated with point contact and the FDLC model, with markers indicating when the object reaches the target angle [latex] heta_d[/latex].](https://arxiv.org/html/2602.03350v1/x7.png)

Modeling the Mess: A Necessary Compromise

Model-based manipulation techniques enhance robustness by explicitly incorporating representations of both the robotic system and its surrounding environment. These models, which can range from kinematic descriptions to dynamic simulations incorporating friction and compliance, allow controllers to predict the outcomes of actions and proactively mitigate potential failures. By simulating interactions before execution, these methods enable planning algorithms to generate trajectories that avoid unstable configurations or excessive forces. Furthermore, model-based approaches facilitate adaptation to changing conditions, as the model can be updated based on sensor data to improve accuracy and predictive capability. This contrasts with model-free reinforcement learning, which relies on trial-and-error and can be less reliable in complex or safety-critical scenarios.

Model-based control facilitates manipulation strategies that explicitly incorporate contact dynamics, moving beyond open-loop trajectories. This allows the system to predict and react to forces generated during contact with the environment, improving robustness to external disturbances and modeling inaccuracies. By planning trajectories that maintain stable contact, or actively adjusting to unexpected contact events, these methods enable robots to perform tasks with increased reliability and adaptability, particularly in scenarios involving uncertain or changing environments. This capability is crucial for tasks like assembly, grasping deformable objects, and locomotion over uneven terrain, where consistent contact is essential for successful operation.

The Point Contact Model simplifies initial robotic manipulation calculations by representing contact interactions as occurring at discrete points, rather than across continuous surfaces. This abstraction allows for the derivation of closed-form solutions for forces and motions during contact, significantly reducing computational complexity. While neglecting the detailed geometry of contact, the model accurately captures essential dynamics like normal and friction forces – typically modeled as [latex]F_n = \lambda \cdot n[/latex] for normal force and [latex]F_f = \mu \cdot \lambda \cdot t[/latex] for friction, where λ is the normal compliance, [latex]n[/latex] is the normal vector, μ is the coefficient of friction, and [latex]t[/latex] is the tangential vector. This approach enables rapid prototyping and control design before incorporating more complex, computationally expensive contact models.

The performance of model-based robust control strategies is directly correlated with the fidelity of the contact models utilized; simplified models, while computationally efficient, may fail to accurately represent complex contact dynamics, leading to instability or suboptimal performance. Conversely, highly detailed models, incorporating factors such as friction, compliance, and surface geometry, demand significant computational resources for real-time implementation. The selection of an appropriate contact model therefore requires a trade-off between accuracy and computational cost, and is heavily influenced by the specific manipulation task and the robot’s capabilities. Furthermore, model inaccuracies stemming from unmodeled dynamics, sensor noise, or environmental variations can significantly degrade performance, necessitating robust estimation and adaptation techniques to compensate for these uncertainties.

Embracing Imperfection: Relaxed Models and Optimization

Traditional robotic contact models often assume idealized conditions, such as perfectly defined contact points and frictionless surfaces. Relaxed contact models depart from this approach by explicitly incorporating uncertainty and non-ideal behavior in contact representations. This is achieved by allowing for distributions over contact locations, orientations, and friction coefficients, rather than relying on single, precise values. The rationale is that real-world interactions invariably involve imperfect contact due to factors like surface roughness, material deformation, and sensor noise. By acknowledging these imperfections, relaxed models provide a more accurate and robust basis for trajectory planning and control, particularly when dealing with complex manipulation tasks and unpredictable environments.

The generation of feasible trajectories for robotic hardware is significantly improved by relaxing the assumption of perfect contact. Traditional motion planning often relies on idealized contact models, which are not representative of real-world scenarios involving surface imperfections, material compliance, and external disturbances. These imperfections can lead to trajectory tracking errors and even task failure. By incorporating a degree of tolerance for non-ideal contact-allowing for slight deviations from perfect adherence-the resulting trajectories become more robust to these real-world effects. This relaxation enables the robot to maintain stable contact and successfully execute the desired task despite the inherent uncertainties and imperfections present in the environment and hardware. Consequently, relaxed contact models facilitate the implementation of more reliable and practical robotic systems.

Bi-level optimization, when integrated with optimization-based dynamics, facilitates trajectory generation by formulating the problem as a nested optimization. The inner level focuses on solving the robot’s dynamic equations to determine states and controls, subject to both kinematic and dynamic constraints. This inner optimization produces a nominal trajectory. The outer level then optimizes over trajectory parameters to minimize a cost function, while simultaneously satisfying contact constraints – ensuring feasible interactions between the robot and its environment. This hierarchical structure allows for the simultaneous consideration of robot dynamics, actuator limits, and contact force/position requirements, resulting in trajectories that are both dynamically feasible and compliant with environmental constraints. The optimization-based dynamics component employs mathematical programming to directly incorporate these constraints into the trajectory generation process, improving robustness and performance compared to traditional trajectory planning methods.

Evaluation of the Force-Distributed Line Contact (FDLC) model in a box rotation task demonstrated a reduction in both control effort and travel distance when compared to a traditional point contact model. Specifically, the FDLC model exhibited improved robustness to both contact slip and geometric inaccuracies during trajectory execution. Quantitative results, detailed in Figs. 5 & 7, indicate that distributing the contact force across a line, rather than concentrating it at a single point, allows for more stable and efficient manipulation, particularly in scenarios with imperfect contact conditions.

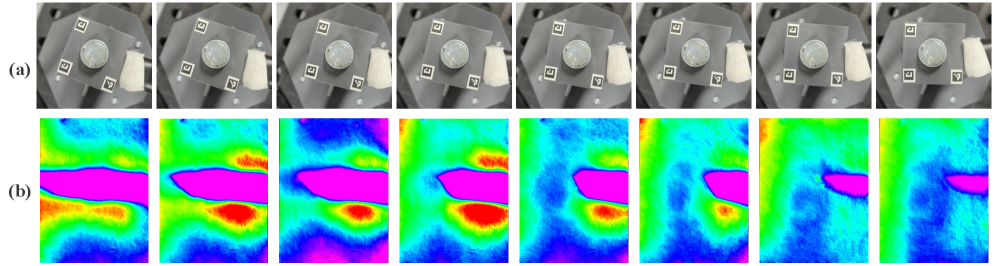

Integrating tactile sensors, such as the GelSight sensor, significantly enhances the perception of contact in robotic manipulation. These sensors provide high-resolution surface normal and force feedback, allowing for the detection of slip, contact location, and contact force magnitude. This data is crucial for refining relaxed contact models by providing ground truth for contact state estimation, enabling the system to adapt to imperfect contact and geometry errors. The resulting feedback loop improves trajectory tracking, reduces reliance on precise modeling, and ultimately enhances the robustness and performance of robotic systems in real-world environments.

![Trajectories generated by the FDLC and point contact models ([latex] heta_{FDLC}[/latex] and [latex] heta_{point}[/latex], respectively) accurately track the desired box orientation ([latex] heta_d[/latex]) and produce corresponding contact forces.](https://arxiv.org/html/2602.03350v1/x8.png)

From Lab to Reality: System Integration and Future Directions

The seamless integration of visual pose estimation, leveraging the distinct patterns of ‘ArUco Markers’, with the capabilities of the ‘UR5e Robot’ establishes a robust framework for accurate object tracking and refined manipulation. This system allows the robot to dynamically perceive an object’s position and orientation in real-time, translating visual data into precise motor commands. By continuously monitoring the ArUco Markers affixed to a target object, the UR5e can adjust its movements, compensating for potential disturbances or inaccuracies in initial positioning. This visual guidance is particularly crucial for tasks demanding high precision, such as assembly, pick-and-place operations, and delicate interactions with fragile components, ultimately enhancing the robot’s adaptability and reliability in complex environments.

A robust robotic manipulation system emerges from the synergistic integration of relaxed contact models, tactile feedback, and visual tracking technologies. By moving beyond the limitations of traditional point-contact assumptions, relaxed models allow the robot to better anticipate and respond to subtle changes in contact forces during interaction with objects. This is further enhanced by incorporating tactile feedback, providing real-time data on contact location and pressure, and visual tracking, which provides contextual awareness of the object’s pose and surroundings. Consequently, the system demonstrates improved performance across a diverse set of manipulation tasks, effectively handling objects with varying shapes, sizes, and surface properties, and adapting to unpredictable scenarios with greater reliability and precision.

Rigorous experimentation revealed a significant performance advantage for the Flexible Data-Limited Contact (FDLC) model in robotic trajectory tracking. Specifically, the FDLC model consistently generated trajectories exhibiting a closer alignment to the desired yaw angle when compared to a traditional point contact model, as visually demonstrated in Figure 9. This improved accuracy stems from the FDLC model’s ability to better represent the nuanced contact dynamics between the robot and the manipulated object, resulting in more precise and reliable control during complex manipulation tasks. The findings underscore the potential of advanced contact models to enhance the dexterity and adaptability of robotic systems, paving the way for more sophisticated applications.

The convergence of robust visual tracking, relaxed contact modeling, and tactile feedback yields a marked improvement in the reliability and adaptability of robotic manipulation systems. This advancement moves beyond the limitations of traditional methods, enabling robots to handle a greater diversity of objects and navigate more complex, unpredictable scenarios. Consequently, the potential applications of this technology are expanding rapidly, particularly within manufacturing environments where automation of intricate assembly tasks is crucial, and in healthcare, where robots can assist with delicate procedures or provide personalized assistance with increased precision and safety. The heightened robustness and adaptability promise to unlock new levels of efficiency and open doors to robotic solutions previously considered impractical or too risky.

The future of robotic manipulation hinges on increasingly sophisticated sensory input and responsive control systems. Current research is actively exploring advanced tactile sensors capable of discerning nuanced object properties – texture, deformation, and slippage – far beyond the capabilities of existing technology. Simultaneously, adaptive control algorithms are being developed to interpret this rich sensory data and dynamically adjust robotic movements, allowing for real-time compensation for uncertainties and disturbances. This synergistic development promises to move beyond pre-programmed routines, enabling robots to handle delicate or unpredictable objects with greater dexterity and reliability. Such advancements are poised to unlock entirely new applications, particularly in fields requiring fine motor skills and human-robot collaboration, and will ultimately redefine the boundaries of robotic autonomy.

The pursuit of increasingly sophisticated contact models feels…familiar. This paper’s Force-Distributed Line Contact (FDLC) approach, while clever in distributing force for manipulation, simply adds another layer of complexity to a domain already brimming with it. It’s a refinement, certainly, but one destined to become tomorrow’s tech debt as requirements inevitably shift. As Brian Kernighan once said, “Debugging is twice as hard as writing the code in the first place. Therefore, if you write the code as cleverly as possible, you are, by definition, not smart enough to debug it.” The elegance of FDLC will undoubtedly collide with the messy reality of production environments, reminding everyone that a ‘good enough’ point contact model, deployed and working, is often more valuable than a theoretically perfect line contact system still in simulation.

What’s Next?

The elegance of distributing force along a contact line is, predictably, only as robust as the models used to predict that distribution. The current formulation sidesteps the messiness of true Hertzian contact, opting for linearity. It works in simulation, of course. The bug tracker, however, will soon catalog the inevitable deviations when faced with surface imperfections, material creep, and the sheer entropy of a real-world assembly process. The question isn’t whether the model is right, but how gracefully it fails.

Expanding this beyond idealized geometries is the obvious, and most painful, path. Point contact models were simplified because they had to be. Now, the field faces the prospect of bi-level optimization over increasingly complex contact manifolds. The computational cost will, naturally, balloon. It won’t be about finding optimal trajectories; it will be about finding trajectories that can be computed before the robot arm rusts.

Ultimately, this work highlights a familiar pattern. A theoretically cleaner approach is developed, demonstrating benefits in controlled conditions. The real test will be how readily it integrates with existing, deeply flawed, but functional systems. It’s a beautiful theory, and the lab demos are compelling. But the robots don’t deploy – they let go.

Original article: https://arxiv.org/pdf/2602.03350.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Robots That React: Teaching Machines to Hear and Act

- Mobile Legends: Bang Bang (MLBB) February 2026 Hilda’s “Guardian Battalion” Starlight Pass Details

- UFL soft launch first impression: The competition eFootball and FC Mobile needed

- Here’s the First Glimpse at the KPop Demon Hunters Toys from Mattel and Hasbro

- eFootball 2026 Epic Italian League Guardians (Thuram, Pirlo, Ferri) pack review

- Katie Price’s husband Lee Andrews explains why he filters his pictures after images of what he really looks like baffled fans – as his ex continues to mock his matching proposals

- Arknights: Endfield Weapons Tier List

- Davina McCall showcases her gorgeous figure in a green leather jumpsuit as she puts on a love-up display with husband Michael Douglas at star-studded London Chamber Orchestra bash

- Olivia Wilde teases new romance with Ellie Goulding’s ex-husband Caspar Jopling at Sundance Film Festival

- 1st Poster Revealed Noah Centineo’s John Rambo Prequel Movie

2026-02-05 03:58