Author: Denis Avetisyan

Researchers have developed a modular, deformable surface that enables adaptable and distributed grasping of multiple objects with a surprisingly low number of actuators.

![The MANTA-RAY platform demonstrates multi-object target reaching capabilities through both hardware implementation and simulation on a [latex]3 \times 3 \times 3[/latex] modular configuration, extending to single-object reach on a smaller [latex]2 \times 2 \times 2[/latex] platform-a scalable architecture hinting at inherent limitations as complexity increases.](https://arxiv.org/html/2601.21884v1/figs/target/sim3x3.png)

This work introduces MANTA-RAY, a multi-modular soft robotic platform for distributed control and heterogeneous object manipulation.

While dense actuator arrays enable complex manipulation on soft surfaces, their scalability is limited by increasing system complexity. This work introduces the ‘Multi-Modular MANTA-RAY: A Modular Soft Surface Platform for Distributed Multi-Object Manipulation’-a novel, fabric-based platform that achieves scalable object handling through distributed control and reduced actuator density. By employing a modular design and a geometric transformation-driven PID controller, the multi-module MANTA-RAY successfully manipulates diverse objects-including fragile items-and enables parallel manipulation across larger areas. Could this approach unlock more adaptable and robust robotic systems for real-world applications requiring versatile object handling?

The Inevitable Failure of Rigid Grasping

Conventional robotic grippers, often relying on parallel-jaw or suction-cup mechanisms, frequently falter when confronted with the unpredictable nature of real-world objects. These designs excel in structured environments handling identical items, but struggle with variations in shape, size, fragility, or surface texture. The limitations stem from a lack of nuanced control and the inability to dynamically adjust to an object’s unique geometry. A simple grasp, effective on a standardized cube, proves inadequate for irregularly shaped produce, delicate electronics, or tools requiring precise orientation. This inherent inflexibility necessitates human intervention in many automation scenarios, hindering the potential for fully autonomous robotic systems and limiting their widespread applicability in diverse industries.

Current robotic manipulation systems frequently falter when confronted with the unpredictable nature of real-world objects, largely due to a lack of adaptability. While capable of performing repetitive tasks with standardized items, these systems struggle with variations in shape, size, and material properties – a commonplace occurrence outside of controlled factory settings. This inflexibility stems from reliance on pre-programmed grasps and rigid end-effectors, which cannot conform to the unique contours of each object. Consequently, automation efforts are often limited to highly structured environments, and the broader deployment of robots in fields like logistics, agriculture, and domestic assistance remains significantly hindered. Addressing this limitation requires a shift towards more versatile manipulation strategies, capable of dynamically adjusting to the characteristics of whatever object is being handled.

The limitations of conventional robotic grasping are driving a shift towards manipulation strategies centered on adaptable surfaces. Rather than relying on pre-defined grips, researchers are developing systems that conform to an object’s unique geometry, distributing forces across a broader contact area. This approach-often utilizing soft robotics, granular materials, or electrostatic adhesion-allows for a more secure and versatile hold on objects with irregular shapes, delicate structures, or varying material properties. These conforming surfaces promise to overcome the challenges posed by real-world variability, enabling robots to reliably handle a wider range of items and paving the way for more robust and flexible automation in manufacturing, logistics, and even healthcare.

![The MANTA-RAY platform, a [latex]1 \times 1 \times 0.7[/latex] meter multi-modular system utilizing nine textile actuators and an Arduino Uno controller, demonstrates adaptive manipulation of diverse objects, as shown in simulation and physical experiments.](https://arxiv.org/html/2601.21884v1/figs/img1.png)

The Illusion of Control: Introducing MANTA-RAY

The MANTA-RAY platform employs a flexible fabric sheet as its primary grasping interface, coupled with a matrix of individually controlled linear actuators positioned beneath the surface. These actuators, when activated, induce localized deformations in the fabric, allowing it to conform to objects with varying geometries and surface properties. The density and arrangement of these actuators determine the granularity of control and the platform’s ability to execute complex grasping motions. This system achieves adaptable grasping without relying on traditional rigid manipulators or pre-defined gripper shapes, enabling it to handle a wider range of object types and sizes.

The MANTA-RAY platform achieves object manipulation through controlled deformation of its fabric surface. This deformation is enacted by an underlying array of linear actuators which raise and lower portions of the fabric, allowing it to envelop objects of varying size and geometry. By conforming to the object’s contours, the platform creates a distributed contact area, maximizing friction and providing a stable grasp. This method eliminates the need for discrete, rigid fingers, and instead relies on the fabric’s adaptability to secure the object without applying concentrated pressure that could cause damage. The resulting grasp is maintained through continuous adjustment of the actuators, ensuring stability during manipulation.

The MANTA-RAY platform’s design incorporates principles of soft robotics to achieve manipulation without the use of rigid components. This is accomplished through a flexible fabric surface actuated by an array of linear actuators, allowing the system to passively conform to grasped objects. This inherent compliance distributes forces over a larger contact area, reducing localized stress concentrations that could damage fragile or irregularly shaped items. Consequently, the platform minimizes the risk of breakage or deformation during handling, making it suitable for applications involving delicate materials such as produce, biological samples, or glassware.

The Mirage of Scalability: Multi-Modular Configuration

The MANTA-RAY platform’s manipulation capabilities are significantly expanded through a multi-modular configuration. This approach involves physically connecting multiple independent manipulation modules to create a larger, unified manipulation surface. Each module contributes to the overall workspace, effectively increasing the system’s reach and allowing for manipulation of objects exceeding the dimensions of a single module. This interconnected design facilitates the creation of a scalable manipulation system, enabling adaptation to diverse task requirements and object sizes without requiring a complete redesign of the core robotic components.

Effective multi-modular manipulation relies on precise actuator placement to minimize discontinuities during object transfer and maintain consistent control. Specifically, actuator spacing must account for the range of motion of each module and the characteristics of the manipulated object to prevent jerking or loss of contact. Careful consideration of this spacing ensures smooth transitions as an object moves from the workspace of one module to the next, allowing for coordinated movements across the entire interconnected surface. Insufficient spacing can lead to control instability, while excessive spacing reduces the system’s ability to maintain consistent force or position control during transfers.

The multi-modular configuration of the MANTA-RAY platform directly enables object transfer across its surface, expanding the scope of possible manipulation tasks. By interconnecting multiple modules, the system overcomes the workspace limitations of a single unit, allowing objects to be moved and manipulated over a larger area. This capability is crucial for applications requiring assembly, sorting, or complex rearrangement of items, as it facilitates continuous manipulation without requiring manual intervention to reposition objects between distinct work areas. The resulting extended workspace increases operational efficiency and enables the execution of manipulation sequences that would be impractical or impossible on a traditional, fixed-area platform.

The MANTA-RAY platform demonstrates reliable object manipulation across a one cubic meter (1x1x1 meter) workspace with a surprisingly limited actuation count of nine actuators. This efficiency is achieved through a strategic arrangement and coordinated control of these actuators, distributing their influence across the entire manipulation surface. The system is not reliant on an actuator for every point of contact or degree of freedom; instead, it leverages the interconnected modular design to extend the effective reach and capability of each actuator, enabling manipulation throughout the 1x1x1 meter volume despite the minimal hardware investment.

The MANTA-RAY platform utilizes distributed control strategies to coordinate movements across multiple modules during parallel manipulation. This approach divides the computational load, enabling real-time control even with an expanded manipulation surface. Specifically, the system maintains a consistent control frequency of 20 Hz while simultaneously managing multiple modules, which is critical for stable and accurate object handling. This is achieved through localized control loops within each module, combined with a communication network facilitating data exchange and coordinated motion planning, avoiding the performance bottlenecks associated with centralized control architectures.

![On a hardware platform, the robot successfully reaches for various objects, consistently positioning them within a [latex]3[/latex] cm threshold of the target (red star) after starting from an initial position (green circle) along a defined path.](https://arxiv.org/html/2601.21884v1/figs/target/cylinder_target_reaching_20251027-170827_trajectory.png)

The Inevitable Limits of Coordinated Transfer

The system achieves object transfer through a carefully orchestrated interplay of coordinated actuation, enabling modules to pass items via controlled sliding and rolling motions. This strategy moves beyond simple grasping and releasing; instead, it relies on precise movements calculated to maintain object momentum and stability during the handover process. Actuators within each module work in concert, applying forces that guide the object along a predetermined trajectory, minimizing disruptions and ensuring a smooth transition between modules. This approach allows for reliable object transfer even with varying object shapes – as demonstrated by differing levels of precision for sphere and cube passing – and represents a key step towards more complex cooperative robotic behaviors.

To facilitate efficient object transfer between robotic modules, a sophisticated path planning strategy leverages the principles of Manhattan geometry. This approach simplifies movement to cardinal directions – effectively restricting motion to aligned pathways – allowing the system to rapidly calculate the shortest sequence of modules an object must traverse. By prioritizing these rectilinear routes, the planning algorithm minimizes overall travel distance and reduces the time required for object handover. The resultant paths aren’t merely about brevity; they represent a significant optimization for energy expenditure and operational speed, ensuring a streamlined and effective transfer process. This focus on Manhattan distance contributes to the system’s overall robustness and scalability, as it simplifies the computational demands of path planning even in complex, multi-module configurations.

Precise object manipulation relies on a sophisticated interplay between desired movement and actuator control, achieved through the implementation of geometric transformation algorithms. These algorithms effectively translate a target object position and orientation into the specific configurations required of each actuator within the system. By calculating the necessary rotations and translations, the algorithms account for the kinematic relationships between actuators and the object, ensuring accurate positioning despite the complexities of multi-module coordination. This computational process considers factors such as actuator reach, joint limits, and potential collisions, generating a precise set of instructions that enable smooth and reliable object transfer. The resulting accuracy allows the system to consistently achieve movements with minimal error, as demonstrated by positioning metrics recorded during experimentation.

A key achievement of this robotic system lies in its precision during object transfer; the mean positioning error consistently remains below 1 centimeter. This level of accuracy is enabled by a tightly integrated approach to path planning and actuation control, ensuring objects are reliably delivered to their intended destinations. Rigorous testing, conducted through both MuJoCo simulation and real-world OptiTrack experiments, confirms this performance across a variety of object shapes, including spheres and cubes, and demonstrates the robustness of the system even with minor disturbances. Such precise manipulation capabilities are crucial for advanced robotic applications requiring delicate handling and reliable object exchange, paving the way for more complex automated tasks.

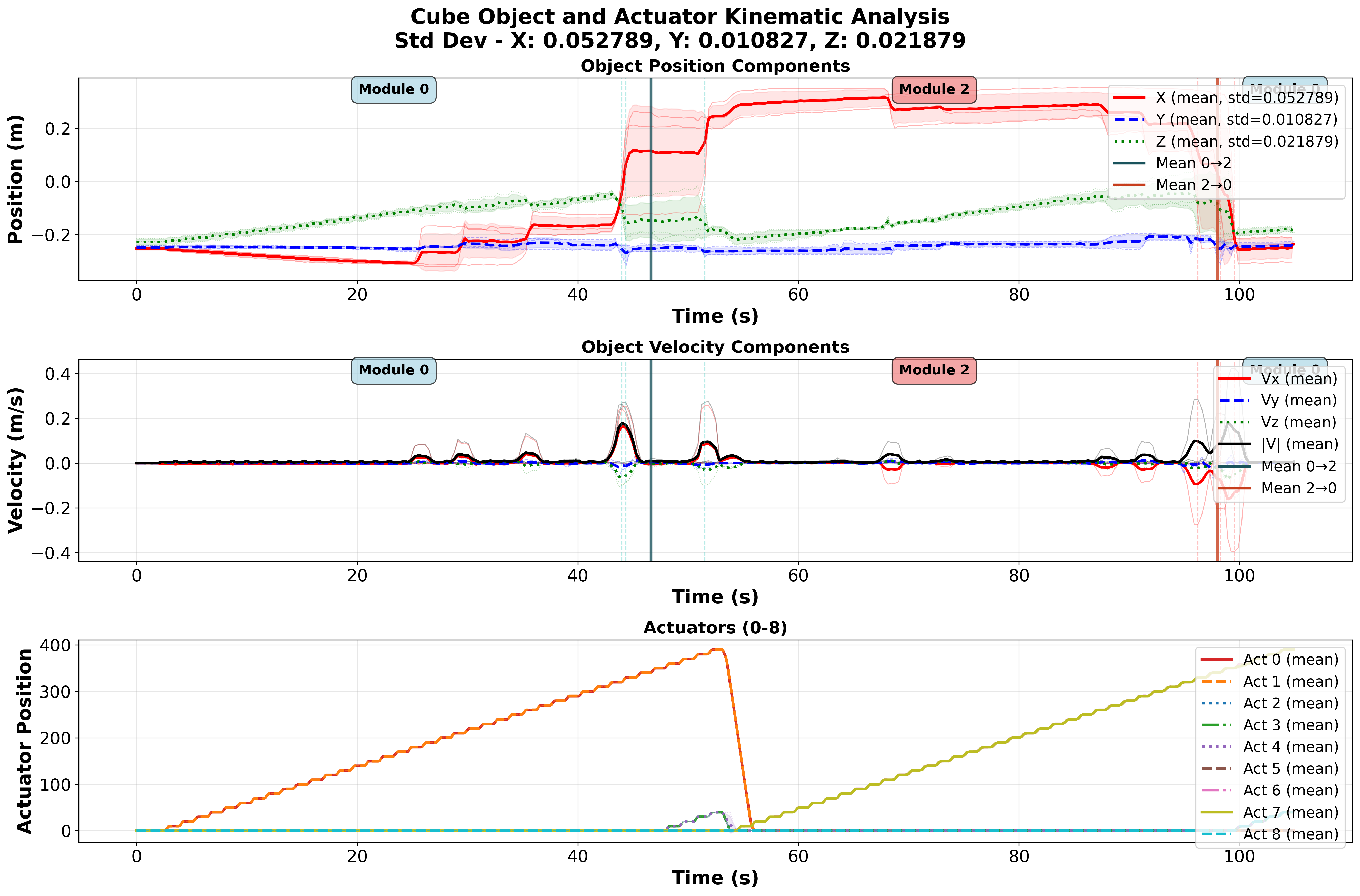

Rigorous testing of the object transfer system reveals a high degree of precision in both sphere and cube manipulation. Across the three spatial dimensions, sphere passing exhibited remarkably low standard deviations – 0.0085 m, 0.0048 m, and 0.0049 m, respectively – indicating consistent and accurate placement. While cube passing demonstrated slightly larger deviations – 0.0528 m, 0.0108 m, and 0.0219 m – these values still represent a substantial achievement in robotic handling, suggesting the system effectively adapts to differing object geometries and maintains a reliable transfer capability. These metrics validate the coordinated actuation and geometric transformation algorithms as effective methods for precise object manipulation in dynamic robotic systems.

Rigorous validation confirms the coordinated object transfer system’s performance across simulated and physical environments. Utilizing the MuJoCo physics engine, the system underwent extensive testing to refine algorithms and predict behavior before implementation on a physical platform. This was then complemented by OptiTrack motion capture experiments, providing ground truth data to assess the system’s accuracy and repeatability in the real world. These combined efforts demonstrate the system’s robustness, consistently achieving precise object manipulation despite variations in initial conditions and external disturbances, and solidifying its potential for reliable operation in complex scenarios.

The pursuit of scalable manipulation, as demonstrated by the MANTA-RAY system, inevitably introduces layers of complexity. This work, with its modular approach to distributed control, isn’t about building a solution, but cultivating a responsive ecosystem. As Ken Thompson observed, “There’s no such thing as a finished program.” The system’s inherent adaptability, allowing it to handle heterogeneous objects through a limited actuator count, feels less like a triumph of engineering and more like a graceful acceptance of future limitations. The perfect architecture remains a myth, yet it’s in striving for it that such elegant, flexible systems emerge – systems destined to evolve beyond their initial design, accepting that everything optimized will someday lose flexibility.

What Lies Ahead?

The proliferation of modular robotic systems, as demonstrated by MANTA-RAY, invites a reassessment of control paradigms. The reduction in actuator count, while laudable, merely shifts the burden – not eliminates it. The true challenge isn’t minimizing actuation, but accepting the inevitability of unpredictable states. Monitoring, then, becomes the art of fearing consciously, a constant anticipation of emergent behaviors rather than a quest for absolute command. This platform will not yield perfect manipulation; it will offer increasingly nuanced revelations about the limits of control itself.

Scalability, frequently invoked as a primary goal, often masks a deeper anxiety: the desire to build systems that outgrow their designers. MANTA-RAY’s architecture, while adaptable, is still a prophecy of future failure. The heterogeneity of manipulated objects, and the surfaces themselves, will inevitably expose the brittleness of any pre-defined control scheme. The field must move beyond attempting to solve manipulation and embrace the design of systems that recover gracefully from its inherent messiness.

True resilience begins where certainty ends. The next iteration will not be about finer control or increased precision. It will be about systems capable of self-diagnosis, self-repair, and – crucially – the capacity to learn from their own failures, transforming unexpected outcomes into opportunities for adaptive reconfiguration. The goal is not a flawless machine, but a persistently evolving ecosystem.

Original article: https://arxiv.org/pdf/2601.21884.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Heartopia Book Writing Guide: How to write and publish books

- Gold Rate Forecast

- Battlestar Galactica Brought Dark Sci-Fi Back to TV

- January 29 Update Patch Notes

- Genshin Impact Version 6.3 Stygian Onslaught Guide: Boss Mechanism, Best Teams, and Tips

- Learning by Association: Smarter AI Through Human-Like Conditioning

- Mining Research for New Scientific Insights

- Robots That React: Teaching Machines to Hear and Act

- Katie Price’s new husband Lee Andrews ‘proposed to another woman just four months ago in the SAME way’

- UFL soft launch first impression: The competition eFootball and FC Mobile needed

2026-02-01 20:37