Author: Denis Avetisyan

A new framework combines machine learning prediction with human oversight to dramatically accelerate the creation of optimized structural designs.

This review details HiTopAI, a human-in-the-loop topology optimization system leveraging AI to predict user-defined modification regions and enhance structural performance.

While topology optimization holds immense promise for creating high-performance engineering structures, its widespread adoption is hindered by computational cost and limited user control. This paper, ‘AI-Guided Human-In-the-Loop Inverse Design of High Performance Engineering Structures’, introduces a novel framework that integrates a machine learning co-pilot to predict user preferences during the design process. By anticipating desired modification regions, this human-in-the-loop approach accelerates optimization and, in demonstrated examples, improves structural performance by up to 39% with minimal time overhead. Could this AI-guided methodology represent a paradigm shift in how engineers design complex structures, fostering both efficiency and innovation?

Breaking the Mold: The Limits of Traditional Topology Optimization

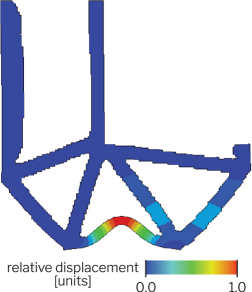

Conventional topology optimization, a powerful technique for generating innovative designs, fundamentally depends on repeated computational simulations. Each iteration involves defining a design space, predicting its performance under given loads using finite element analysis – a method that discretizes a complex problem into smaller, manageable pieces – and then refining the design based on the results. This process, while effective, is inherently computationally expensive, particularly for intricate geometries or demanding performance criteria. The need to repeatedly solve \nabla^2 \phi = 0 – Laplace’s equation representing stress distribution – across numerous design iterations quickly strains available computational resources and limits the speed at which designers can explore the vast design landscape. Consequently, achieving truly optimized structures often requires significant processing time and powerful hardware, presenting a practical barrier to widespread adoption and rapid innovation.

Successfully navigating designs resistant to complex failure modes, such as buckling, presents a considerable challenge for conventional topology optimization. While algorithms can effectively optimize for stiffness or strength under simple loads, predicting and preventing instability requires a nuanced understanding of structural behavior that often exceeds the capabilities of automated processes. Consequently, engineers frequently must manually refine designs generated by these tools, introducing geometric constraints, adjusting material distributions, or implementing specialized bracing strategies. This intervention is critical for ensuring structural integrity, but it introduces a reliance on expert knowledge and slows down the design cycle, as iterative simulations and manual adjustments become necessary to address potentially catastrophic failure scenarios not readily captured by the optimization algorithm itself.

The iterative nature of conventional topology optimization, coupled with its reliance on finite element analysis, presents a significant bottleneck in the design process. Each design iteration demands considerable computational power and time, effectively limiting the number of viable concepts that can be explored within a practical timeframe. This sluggishness isn’t merely a matter of inconvenience; it actively stifles innovation by restricting designers from rapidly prototyping, testing, and refining designs. The substantial resource requirements – processing time, memory, and energy – also create a barrier to entry for smaller teams or those lacking access to high-performance computing infrastructure, ultimately slowing the pace of advancement in fields reliant on optimized structural designs.

The AI Co-Pilot: Introducing HiTopAI

HiTopAI implements a human-in-the-loop topology optimization framework where an AI co-pilot assists in iterative design refinement. This system departs from fully automated optimization by actively incorporating human engineering judgment into the process. The framework functions by presenting suggested design modifications, generated by the AI, to a human designer who then validates or rejects them. This feedback loop allows the AI to learn from human expertise and improves the quality and feasibility of the resulting topology. The iterative nature of this process aims to balance computational efficiency with practical design considerations, ultimately leading to more robust and manufacturable designs.

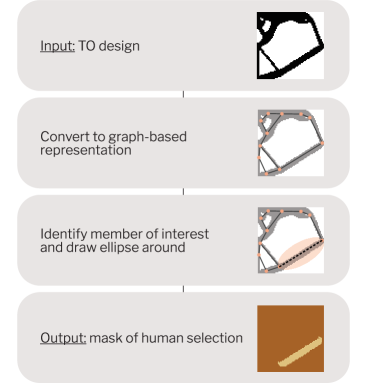

HiTopAI’s AI co-pilot employs a U-Net, a convolutional neural network architecture commonly used for image segmentation, to analyze design geometries and predict areas suitable for material modification. The U-Net processes input data through an encoding path, which captures contextual information, and a decoding path, which enables precise localization of optimal regions. This network is trained on datasets of successful designs, allowing it to identify patterns and correlations between geometry and performance. The output of the U-Net is a probability map indicating the likelihood that material addition or removal in a given region will improve the design’s objective function, such as minimizing weight or maximizing stiffness. The network’s convolutional layers extract hierarchical features, while skip connections between the encoding and decoding paths preserve fine-grained details crucial for accurate prediction.

Traditional topology optimization relies on iterative computational algorithms to achieve desired design performance, often requiring significant processing time and resulting in complex geometries. HiTopAI departs from this approach by integrating a U-Net-based artificial intelligence co-pilot that analyzes existing design patterns and learns from human modifications. This allows the system to predict optimal material distribution based on learned relationships, effectively shifting from a purely algorithmic process to an intelligent system informed by both data and expert knowledge. The AI’s predictive capability accelerates the optimization cycle and facilitates the creation of designs that reflect practical engineering considerations often absent in purely computational solutions.

HiTopAI’s integration of human insight addresses limitations inherent in automated topology optimization. While computational methods can identify structurally sound designs, they often lack the nuanced understanding of manufacturing constraints, material behaviors under complex loads, and real-world performance requirements. By allowing designers to iteratively refine AI-suggested modifications, HiTopAI leverages human expertise to improve design robustness – specifically, its ability to maintain performance under unexpected conditions or variations in input. This human-in-the-loop process also enhances design efficiency by focusing computational resources on promising areas of the design space, reducing the time and cost associated with purely iterative optimization algorithms.

Synthetic Realities: Training the AI Co-Pilot

The training of the U-Net, a convolutional neural network utilized for design modification prediction, requires a substantial volume of accurately labeled data. Acquiring this data through manual annotation is both time-consuming and resource-intensive, creating a significant bottleneck in the development process. To address this, a synthetic data generation process was implemented. This process programmatically creates training examples, circumventing the need for extensive manual labeling and enabling rapid iteration on the AI co-pilot’s learning capabilities. The generated data aims to replicate the characteristics of real-world design scenarios, providing the U-Net with a diverse and representative dataset for effective training.

The synthetic data generation process constructs training datasets by algorithmically defining topology characteristics and applying established criteria to simulate human design preferences. Specifically, the system identifies and prioritizes structural elements based on metrics such as ‘Longest Structural Member’ – favoring examples with extended geometries – and ‘Most Complex Node’, which highlights areas of intricate connectivity. These criteria are used to generate variations in topology, effectively creating a diverse set of training examples without requiring manual annotation, and ensuring the AI co-pilot learns to recognize and replicate patterns representative of preferred design solutions.

The U-Net’s training incorporates the Adam optimizer, a stochastic gradient descent method that adjusts learning rates adaptively for each parameter, and is guided by the Binary Cross Entropy with Logits Loss function BCEWithLogitsLoss . This loss function calculates the cross-entropy between the predicted probabilities and the true binary labels, facilitating accurate differentiation between correct and incorrect design modification predictions. The combination of Adam optimization and BCEWithLogitsLoss ensures efficient convergence during training and optimizes the U-Net’s ability to accurately identify and predict optimal design modifications based on the synthetic data.

The reliance on manually labeled datasets for training machine learning models presents scalability and cost challenges. Synthetic data generation offers a solution by programmatically creating training examples, effectively circumventing the bottlenecks associated with human annotation. This approach allows for the rapid creation of large, diverse datasets tailored to specific training requirements, such as the U-Net topology optimization process. By automating data creation, development timelines for the AI co-pilot are significantly reduced, and the model can be trained on a scale impractical with manual labeling efforts. This accelerated development cycle enables faster iteration and refinement of the AI co-pilot’s capabilities.

Beyond Optimization: Impact and Future Directions

HiTopAI represents a significant advancement in the field of structural design by dramatically accelerating topology optimization workflows. Traditionally, engineers faced lengthy computational processes when attempting to create lightweight yet robust structures; however, this novel approach leverages artificial intelligence to rapidly iterate through design possibilities. By automating and refining the optimization process, HiTopAI allows for the exploration of a far wider design space than previously feasible, ultimately unlocking the potential for truly innovative and high-performance geometries. This capability is particularly impactful in industries demanding intricate and efficient structures, such as aerospace, automotive, and biomedical engineering, where even marginal improvements in performance can yield substantial benefits.

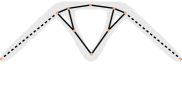

Density-Based Topology Optimization, as integrated within the HiTopAI framework, represents a significant advancement in the pursuit of structurally efficient designs. Unlike traditional methods constrained by predefined shapes, this approach permits material distribution to evolve organically, enabling the creation of highly complex and often counterintuitive geometries. By iteratively removing material where it contributes least to structural performance, the optimization process yields designs with maximized strength-to-weight ratios and enhanced functional capabilities. This freedom in geometrical exploration is particularly valuable when addressing design challenges with complex loading conditions or space constraints, allowing engineers to realize innovative solutions previously unattainable through conventional design practices and fostering a new era of lightweight, high-performance structures.

Recent advancements in generative design leverage artificial intelligence to substantially enhance structural integrity. Specifically, HiTopAI has demonstrated a remarkable 39% improvement in buckling load performance when compared to traditionally designed structures. This signifies a considerable leap in a component’s ability to withstand compressive forces without deformation, directly translating to safer and more durable products. This performance gain is particularly noteworthy as it indicates that AI-driven topology optimization isn’t merely creating novel forms, but genuinely improving the engineering capabilities of the designed components. The improvement suggests potential applications in fields demanding high structural resilience, such as aerospace, automotive engineering, and civil infrastructure, where even incremental increases in load capacity can have significant implications for safety and longevity.

A key benefit of integrating HiTopAI into topology optimization workflows lies in its remarkable efficiency. While achieving a substantial 39% improvement in buckling load performance – a critical metric for structural integrity – the system introduces only a 4% increase in overall design time. This minimal overhead signifies a significant advancement over traditional methods, which often demand extensive computational resources and lengthy processing times for comparable performance gains. The reduced design cycle allows engineers to explore a wider range of design possibilities and iterate more rapidly, fostering innovation and accelerating the development of high-performance structures without sacrificing productivity. This balance between improved performance and maintained efficiency positions HiTopAI as a compelling tool for future engineering applications.

A critical advancement facilitated by HiTopAI lies in its ability to maintain structural integrity during the topology optimization process, as evidenced by a significantly improved graph connectivity rate. Post-modification analysis reveals that 76.0% of the design’s structural elements remain connected and functional, a substantial leap from the 58.3% achieved with traditional skeletonization methods. This heightened connectivity is not merely a numerical improvement; it directly translates to more robust and reliable designs, minimizing the risk of stress concentrations and potential failure points. By preserving a greater degree of structural interdependence, HiTopAI enables the creation of complex geometries without sacrificing performance or dependability, paving the way for innovative engineering solutions.

The pursuit of optimal engineering structures, as detailed in HiTopAI, inherently involves a dance with the unpredictable. The framework doesn’t merely find solutions; it actively probes the design space, inviting modifications and leveraging machine learning to anticipate human preferences. This echoes Andrey Kolmogorov’s sentiment: “The most important discoveries often come from challenging established assumptions and exploring the boundaries of what is known.” The system, much like a seasoned engineer, doesn’t shy away from ‘breaking’ initial designs – identifying areas for refinement through predicted user input. This constant testing of limits, guided by both algorithmic prediction and human intuition, ultimately seeks to reverse-engineer the most efficient and robust structural forms. The core concept of topology optimization, therefore, isn’t about avoiding failure, but rather about systematically finding the points of potential weakness to fortify them.

Beyond the Blueprint

The presented framework, while demonstrating a clear acceleration of the topology optimization cycle, inherently highlights the black box nature of preference prediction. The machine learning co-pilot doesn’t understand design intent; it correlates visual patterns with human choices. This begs the question: how much true innovation is sacrificed at the altar of efficiency? Future work must move beyond simply mirroring existing biases and explore methods to actively challenge a designer’s initial assumptions – perhaps by introducing controlled “errors” into the predicted modification regions, forcing a re-evaluation of the design space.

Furthermore, the current reliance on image segmentation as the primary input modality feels… quaint. Structural performance isn’t solely a visual problem. Integrating multi-physics simulations directly into the preference learning loop, allowing the co-pilot to ‘feel’ the consequences of design choices beyond aesthetics, represents a logical, if computationally demanding, progression. One wonders if the ultimate goal isn’t an AI co-pilot at all, but a system capable of autonomously formulating and testing design hypotheses, relegating the human to the role of a skeptical observer.

Ultimately, this work isn’t about finding the best design, but about systematically dismantling the constraints that limit design exploration. The true measure of success won’t be faster optimization, but the generation of genuinely unexpected, and potentially superior, structural forms – designs that a human, operating alone, would never have conceived. The path forward lies not in refining the existing framework, but in deliberately breaking it, and building something stranger in its place.

Original article: https://arxiv.org/pdf/2601.10859.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Clash Royale Best Boss Bandit Champion decks

- Vampire’s Fall 2 redeem codes and how to use them (June 2025)

- World Eternal Online promo codes and how to use them (September 2025)

- Best Arena 9 Decks in Clast Royale

- Country star who vanished from the spotlight 25 years ago resurfaces with viral Jessie James Decker duet

- ‘SNL’ host Finn Wolfhard has a ‘Stranger Things’ reunion and spoofs ‘Heated Rivalry’

- Solo Leveling Season 3 release date and details: “It may continue or it may not. Personally, I really hope that it does.”

- JJK’s Worst Character Already Created 2026’s Most Viral Anime Moment, & McDonald’s Is Cashing In

- M7 Pass Event Guide: All you need to know

- Kingdoms of Desire turns the Three Kingdoms era into an idle RPG power fantasy, now globally available

2026-01-20 05:35