Author: Denis Avetisyan

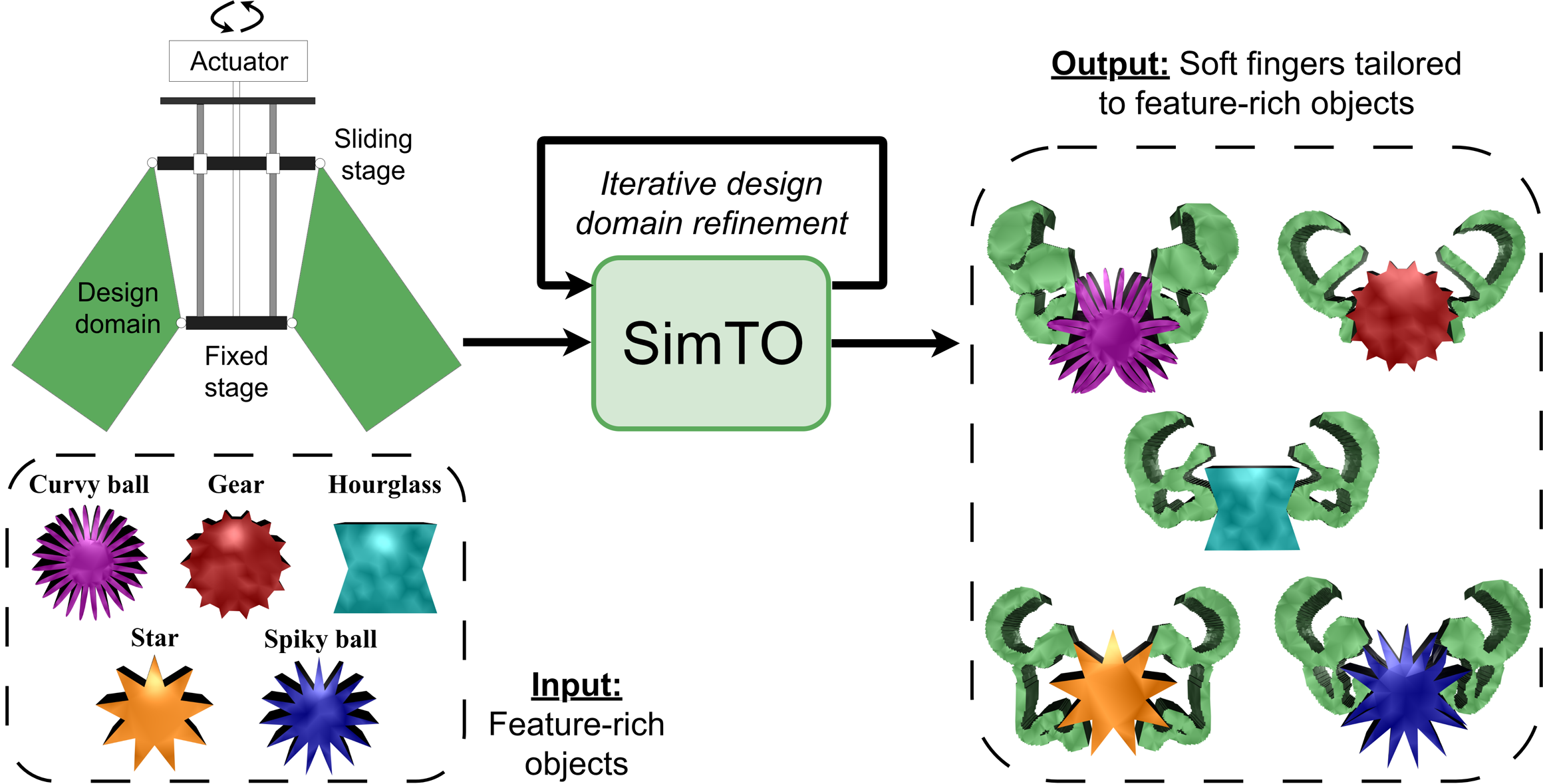

Researchers have developed a new framework that automatically generates custom soft robotic grippers optimized for grasping complex objects, moving beyond the limitations of pre-defined grasp types.

SimTO leverages topology optimization and contact simulation to create bespoke soft grippers designed for objects with varied geometries and design-dependent loads.

While soft robotic grippers excel at handling delicate objects, their application to items with complex geometries and unpredictable contact forces remains a significant challenge. This limitation motivates the development of ‘SimTO: A simulation-based topology optimization framework for bespoke soft robotic grippers’, a novel approach that automates the design of specialized grippers tailored to feature-rich objects. By extracting realistic load cases directly from contact-based physics simulations, SimTO eliminates the need for manual load specification, enabling high-resolution topology optimization. Can this simulation-driven design process unlock a new era of adaptable and robust soft robotic manipulation in diverse applications like manufacturing and agriculture?

The Challenge of Adaptation: Beyond Rigid Grips

Conventional robotic grippers, designed as versatile tools, often fall short when confronted with objects possessing intricate geometries or delicate surfaces. These generalist approaches typically rely on simple, forceful closures, proving inadequate for handling feature-rich items without causing damage or slippage. The inherent challenge lies in the difficulty of adapting to varied object properties – differing weights, fragile components, or irregular shapes – which require nuanced control beyond the capabilities of standard designs. Consequently, automation of tasks involving these complex objects remains a significant hurdle, necessitating the development of specialized gripping solutions capable of replicating the dexterity and sensitivity of a human hand.

Developing robotic grippers capable of reliably handling a diverse range of objects presents a significant engineering challenge, largely due to the iterative nature of design and the complexities of predicting contact forces. Each object’s unique geometry and material properties dictate the forces exerted during grasping, and accurately modeling these interactions is computationally expensive and often requires extensive physical testing. Prototypes must be repeatedly built, tested, and refined to account for unforeseen variables like friction, deformation, and weight distribution – a process that consumes valuable time and resources. The difficulty in anticipating these forces hinders the creation of truly adaptable grippers, pushing designers towards solutions that excel in limited scenarios but struggle with the unpredictable demands of real-world environments.

Current approaches to designing robotic grippers for specific tasks often necessitate the pre-definition of expected loads and forces – a substantial constraint in real-world applications. This reliance on pre-defined parameters limits a gripper’s adaptability when confronted with objects exhibiting unpredictable characteristics, varying weights, or unexpected orientations during the grasping process. Consequently, a gripper optimized for a narrow range of conditions may fail entirely when presented with even slight deviations from its programmed expectations. This inflexibility underscores a critical need for gripper designs capable of dynamically adjusting to unforeseen forces and accommodating the inherent uncertainties present in unstructured environments, paving the way for more robust and versatile robotic manipulation systems.

![This design domain, based on liu2018\\_TObenchmark\\_v2, differs by allowing deformation along [latex]N_f[/latex] simulated gripper-object contact force directions, rotating the input force [latex] \\mathbf{f}_{in} [/latex] by 10[latex]^\circ[/latex], and removing material retention constraints on the lower 80 mm edge.](https://arxiv.org/html/2601.19098v1/figures/design_domain.png)

SimTO: A Framework for Adaptive Design

SimTO implements a novel framework that integrates topology optimization with automated load case generation via contact-based physics simulation. Traditional topology optimization requires pre-defined loads, limiting adaptability in scenarios with variable forces. SimTO circumvents this limitation by utilizing a physics simulator to generate a diverse set of load conditions directly from simulated interactions. These loads, derived from physical simulations of object manipulation or environmental forces, are then automatically applied to the topology optimization process, enabling the creation of designs optimized for a broader range of operational conditions without manual load specification.

Traditional topology optimization requires pre-defined load cases to simulate structural response; however, SimTO circumvents this limitation by dynamically generating loads directly from a physics simulation of the grasping process. This is achieved by simulating the gripper interacting with various objects and extracting the resulting forces and moments as representative load conditions. By eliminating the need for a priori specification of these loads, the framework enables optimization for scenarios where the object’s shape, position, or material properties are unknown or variable, which is particularly advantageous for robotic grippers designed to handle unpredictable objects in unstructured environments. The resulting gripper designs are therefore optimized for robustness and adaptability to a wider range of grasping tasks.

The SimTO framework’s load extraction process relies on contact-based physics simulation to determine forces acting on a design during interaction with objects. This simulation utilizes tools such as Taccel, a finite element analysis engine, to model the physical behavior of components and their environment. Material properties are defined using models like the Neo-Hookean solid, a hyperelastic material model commonly used to represent the behavior of rubber-like materials under large deformations, which is critical for accurately simulating grasping interactions. The resulting simulation data-specifically, the contact forces and moments-are then directly employed as loads in the topology optimization process, eliminating the need for pre-defined load cases.

![SimTO iteratively optimizes 3D compliant mechanisms by alternating between dynamic simulation in the deformed frame [latex]\mathcal{D}[/latex], extraction of in-plane contact forces [latex]\mathcal{R}[/latex], and 2D topology optimization to refine the design.](https://arxiv.org/html/2601.19098v1/figures/method.png)

Under the Hood: The Mechanics of Optimization

The topology optimization framework utilizes the Finite Element Method (FEM) to perform detailed structural analysis of proposed designs. FEM discretizes the design domain into a mesh of elements, each with defined material properties and nodal connectivity. Through this discretization, the framework can approximate the solution to complex structural problems by solving a system of algebraic equations derived from governing physical laws, such as those relating stress, strain, and displacement. This allows for precise evaluation of structural performance metrics – including stiffness, compliance, and stress distribution – under defined loading and boundary conditions, enabling iterative refinement of the design topology to meet specified performance criteria. The accuracy of the analysis is directly dependent on mesh density and element type selection, with finer meshes generally yielding more accurate results at the cost of increased computational time.

The Solid Isotropic Material with Penalization (SIMP) method is utilized as the core algorithm for density-based topology optimization. SIMP operates by assigning a density value to each finite element within the design domain; values approaching 1 represent solid material, while values near 0 represent void. During optimization, these density values are iteratively adjusted based on applied loads and constraints. A penalization factor, typically greater than 1, is applied to the density to promote a clear distinction between solid and void elements, preventing intermediate densities and facilitating the creation of manufacturable designs. This approach allows for efficient exploration of a vast design space by continuously modifying the material distribution until an optimal structural configuration is achieved, meeting specified performance criteria and constraints.

The Optimal Criteria Method (OCM) addresses topology optimization as a multi-objective optimization problem, framing design variables as criteria to be simultaneously satisfied. Unlike gradient-based methods susceptible to local minima, OCM seeks Pareto optimal solutions by iteratively refining the design based on multiple, potentially conflicting objectives – such as minimizing weight and maximizing stiffness. The method employs a sensitivity analysis to determine the influence of each design variable on each objective, then utilizes a weighting scheme to balance competing objectives and drive the optimization process. This improves robustness by avoiding single-point optimization and facilitates the exploration of a range of viable designs, offering a more reliable design process and reducing the risk of suboptimal results.

Expanding the Repertoire: Diverse Grasping Strategies

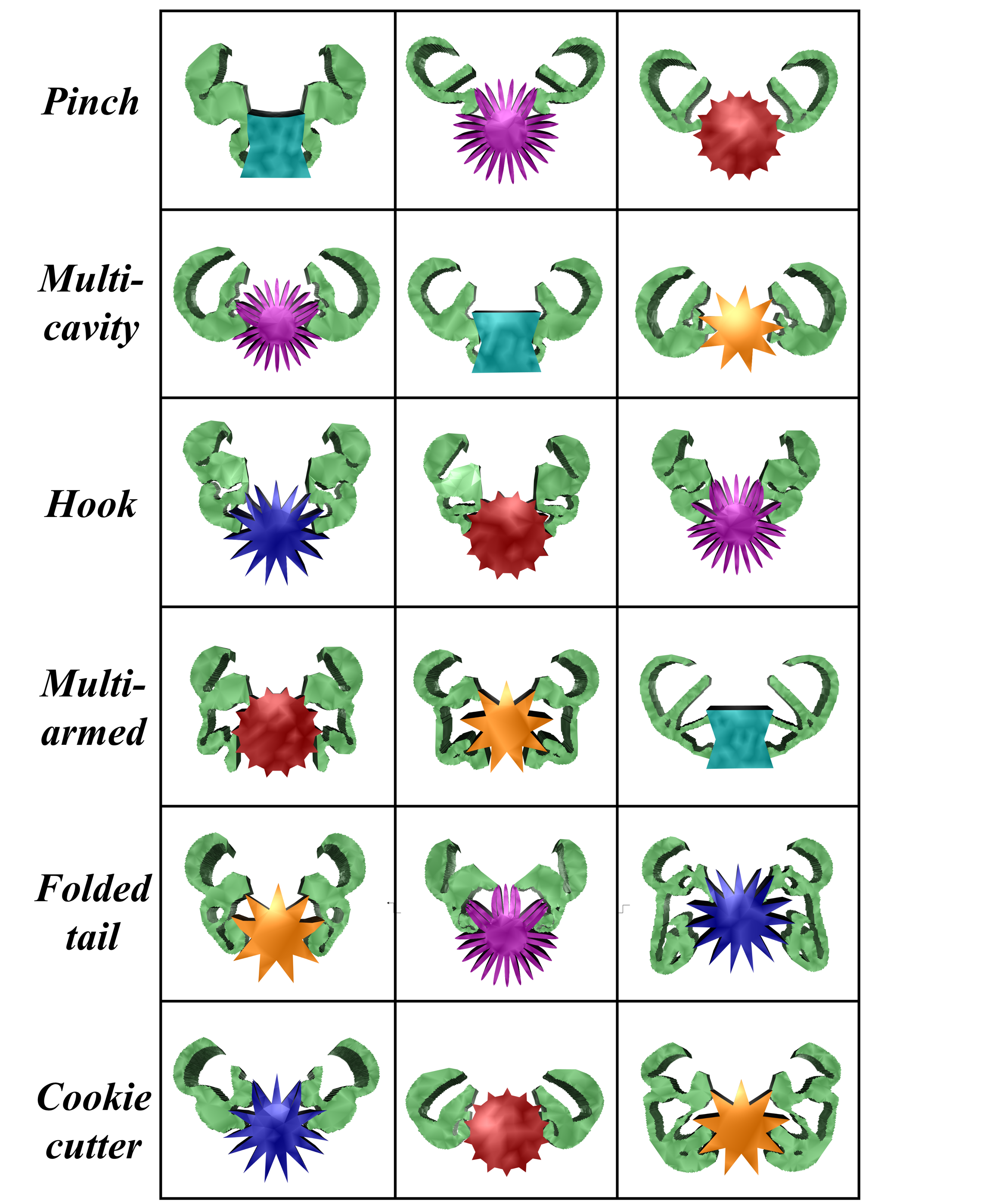

SimTO enables the development of robotic grippers capable of diverse manipulation approaches, tailoring grasp strategies to an object’s unique shape. These strategies include Hook Grasping, ideal for encircling and lifting objects with handles or protrusions; Pinch Grasping, effective for securing objects with flat or cylindrical surfaces; and Cookie Cutter Grasping, which allows a gripper to conform to and enclose irregularly shaped items. By algorithmically exploring design possibilities, SimTO moves beyond the limitations of pre-programmed grips, automatically generating solutions optimized for specific geometries and expanding the range of objects a robot can reliably handle. This adaptability is crucial for real-world applications where robots encounter a vast array of shapes and sizes, demanding a flexible and intelligent approach to grasping.

Beyond conventional grasping approaches, optimized designs generated through SimTO unlock a spectrum of complex manipulation strategies. These include Multi-Cavity Grasping, enabling secure handling of objects with internal voids, and Folded Tail Grasping, which allows for enveloping and stabilizing elongated or flexible items. Perhaps most remarkably, the system facilitates the exploration of Multi-Arm Grasping – coordinating multiple robotic limbs for intricate object manipulation previously considered beyond the reach of automated systems. This progression demonstrates a shift from simple, single-point contact grasps to nuanced, adaptive strategies, significantly broadening the scope of objects a robot can reliably handle and manipulate in unstructured environments.

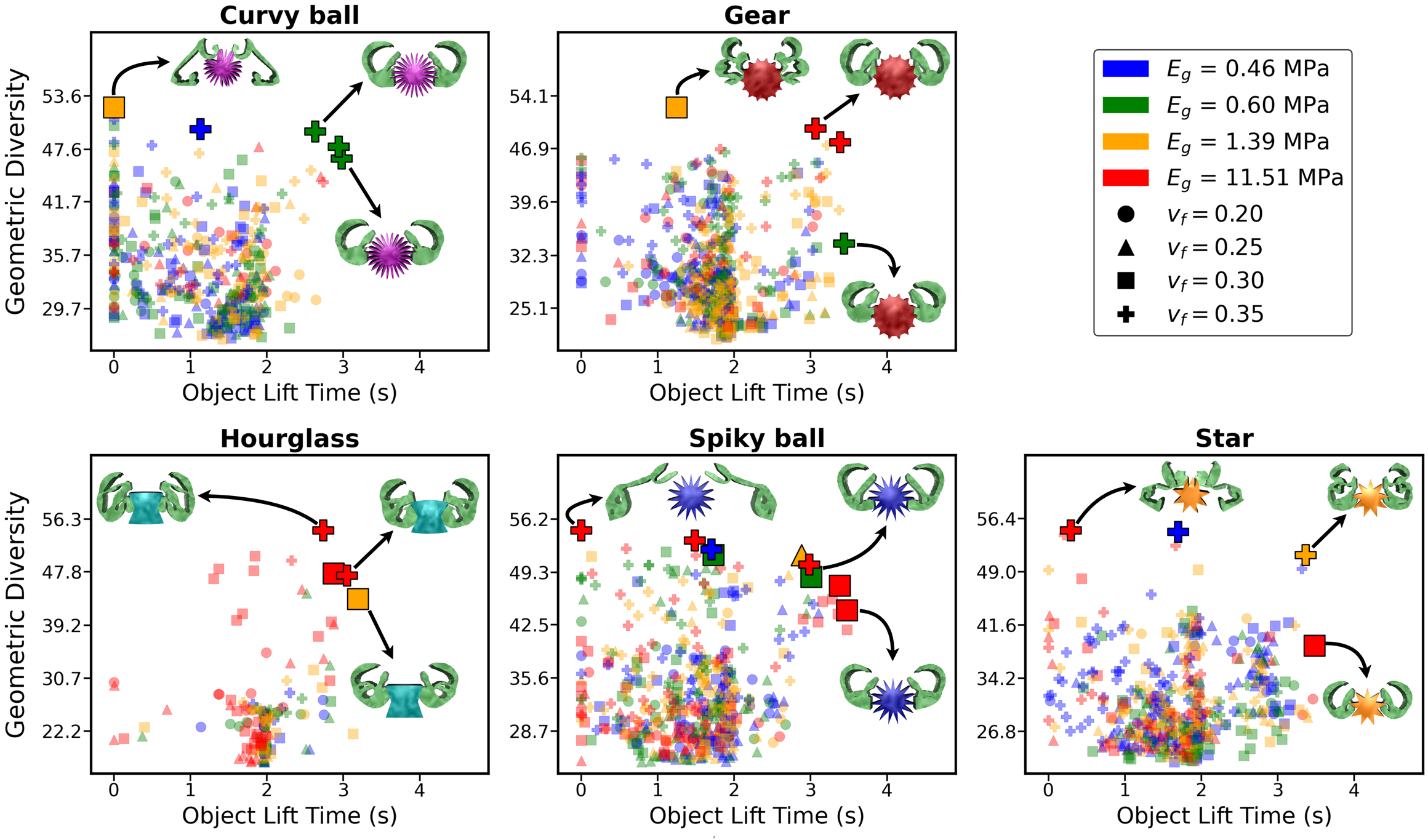

Robotic grasping systems, traditionally constrained by the need for pre-programmed grips tailored to specific objects, are experiencing a leap in versatility through simulation-driven design. Recent advancements demonstrate that optimized gripper designs, generated using the SimTO framework, aren’t limited to handling simple, uniform shapes; instead, they readily adapt to objects with complex geometries and diverse features. This adaptability stems from the system’s ability to rapidly iterate through potential designs, converging on high-performance solutions – remarkably, effective grasping strategies have been identified in as few as one to nine SimTO iterations. This capacity to quickly produce robust, generalized grippers significantly expands the range of objects a robot can reliably manipulate, promising greater autonomy and efficiency in complex tasks and environments.

Recent advancements in robotic grasping have been catalyzed by SimTO, a system capable of autonomously designing effective grippers. Through iterative simulations and optimization, SimTO has successfully identified and implemented six distinct grasping strategies – encompassing approaches like hooking, pinching, and enveloping – that extend beyond traditional robotic manipulation. This isn’t merely a refinement of existing techniques; the system generates novel solutions, including strategies for complex objects and multi-cavity grips, demonstrating a significant expansion in the repertoire of robotic grasping capabilities. The identification of these diverse strategies suggests a pathway towards more adaptable and versatile robots, capable of handling a wider range of objects and tasks with greater efficiency and reliability.

The presented SimTO framework embodies a principle of reductive design. It systematically eliminates unnecessary complexity in the creation of soft robotic grippers, focusing solely on the forces required for successful manipulation. This mirrors the pursuit of essential information – discarding extraneous data to reveal the underlying structure. As Claude Shannon observed, “The most important thing in communication is to convey information with the least amount of redundancy.” SimTO achieves this by eschewing pre-defined load cases, instead deriving necessary parameters directly from physics simulations – a clear instance of minimizing redundancy and maximizing efficient design. The framework’s iterative process distills the optimal form from a multitude of possibilities, arriving at a solution defined by function, not arbitrary complexity.

Beyond the Grip

The presented framework addresses a persistent difficulty: designing for the unpredictable. It moves, commendably, toward a system that requires fewer preconditions – eliminating the need to anticipate every possible grasping scenario. Yet, a system that defines its success by the breadth of its ignorance remains, at its core, a reactive measure. True elegance lies not in accommodating complexity, but in diminishing it at the source.

Future iterations should, perhaps, shift focus from simulating contact to preventing the need for it. A gripper that inherently understands an object’s fragility, rather than simply reacting to applied force, represents a more fundamental resolution. The current reliance on iterative simulation, while effective, implies a degree of structural uncertainty. A system that designs from certainty, rather than toward it, would be a marked improvement.

Ultimately, the pursuit of bespoke grippers is a proxy for a larger challenge: creating systems that function intuitively in unstructured environments. The ultimate test will not be how many objects a gripper can manipulate, but how gracefully it avoids manipulating those it shouldn’t. A system that needs instructions has already failed; simplicity remains the ultimate courtesy.

Original article: https://arxiv.org/pdf/2601.19098.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- Heartopia Book Writing Guide: How to write and publish books

- EUR ILS PREDICTION

- VCT Pacific 2026 talks finals venues, roadshows, and local talent

- Lily Allen and David Harbour ‘sell their New York townhouse for $7million – a $1million loss’ amid divorce battle

- Gold Rate Forecast

- Battlestar Galactica Brought Dark Sci-Fi Back to TV

- January 29 Update Patch Notes

- How to have the best Sunday in L.A., according to Bryan Fuller

- Everything to Know About the Comics Behind Ryan Murphy’s Wild New Series The Beauty

- Streaming Services With Free Trials In Early 2026

2026-01-29 07:02